Global rank:

2,874

/

121,028

Skill pts: 11

About

✨ Mechanical Engineer | CAD • Simulation • MEP Specialist ✨

With 12+ years of cross-functional engineering experience, I bring a strategic blend of design, analysis, and execution. I turn ideas into manufacturable, performance-validated, and field-ready solutions—whether it’s a product, a system, or a full-scale building workflow.

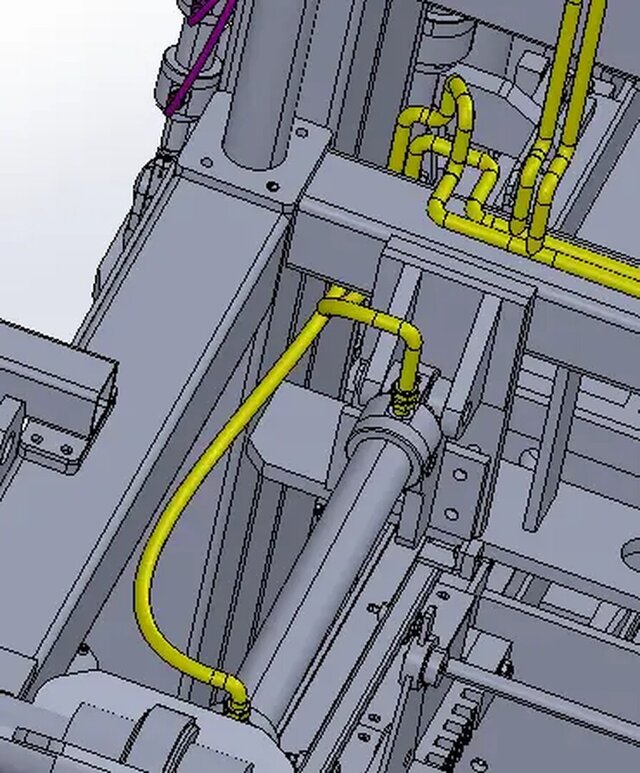

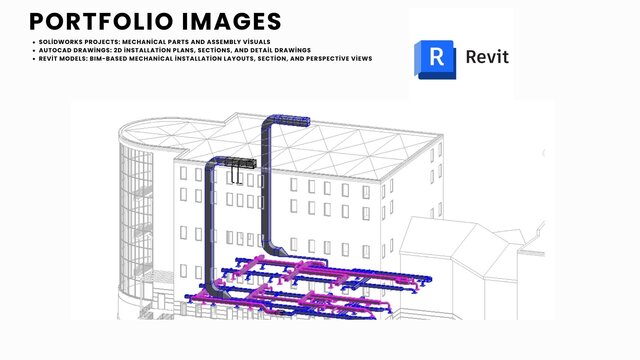

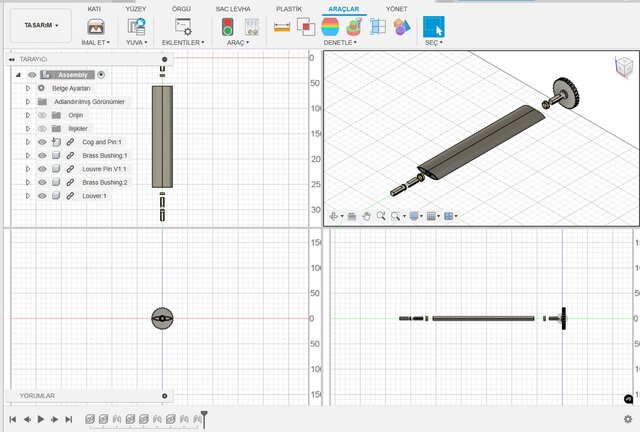

⭐Tools: SolidWorks | Fusion 360 | AutoCAD | Revit | ANSYS | SAP2000 | STA4CAD | Inventor | Excel | MS Project

Core Expertise:

⭐Design & Product Development

End-to-end design of mechanical parts, plastic components, and industrial products—ready for real-world production.

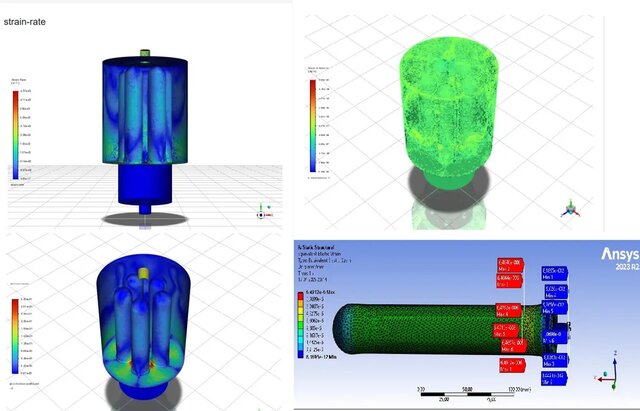

⭐Simulation & Analysis

FEA & CFD-based structural, thermal, and fluid flow validation for optimized, reliable performance.

⭐MEP & Project Coordination

HVAC, plumbing (clean, waste, fire), BIM clash control, BOQ/BOS documentation, and interdisciplinary integration.

Why Work With Me?

⭐Holistic project vision—from concept to execution

⭐Field-tested, buildable solutions

⭐Precision-driven and detail-focused

⭐ Strong communicator across all disciplines

⭐ Fast, focused, and quality-oriented delivery

Let’s connect and make your vision real—with results that are engineered to perform.

... more »

« less

With 12+ years of cross-functional engineering experience, I bring a strategic blend of design, analysis, and execution. I turn ideas into manufacturable, performance-validated, and field-ready solutions—whether it’s a product, a system, or a full-scale building workflow.

⭐Tools: SolidWorks | Fusion 360 | AutoCAD | Revit | ANSYS | SAP2000 | STA4CAD | Inventor | Excel | MS Project

Core Expertise:

⭐Design & Product Development

End-to-end design of mechanical parts, plastic components, and industrial products—ready for real-world production.

⭐Simulation & Analysis

FEA & CFD-based structural, thermal, and fluid flow validation for optimized, reliable performance.

⭐MEP & Project Coordination

HVAC, plumbing (clean, waste, fire), BIM clash control, BOQ/BOS documentation, and interdisciplinary integration.

Why Work With Me?

⭐Holistic project vision—from concept to execution

⭐Field-tested, buildable solutions

⭐Precision-driven and detail-focused

⭐ Strong communicator across all disciplines

⭐ Fast, focused, and quality-oriented delivery

Let’s connect and make your vision real—with results that are engineered to perform.

Service offers

Experience

-

Freelance Mechanical & Structural Engineer | Design • Simulation • MEP

Freelancer.com · Freelance

Oct 2018 –

Present

7 yrs 3 mos

Australia

Providing end-to-end engineering solutions since 2018, I specialize in mechanical design, structural analysis, and MEP coordination. My projects include product development, FEA & CFD simulations, HVAC & plumbing system design, and interdisciplinary project management for global clients.

Delivered manufacturable and field-ready designs for products and buildings.

Performed advanced simulations for structural, thermal, and fluid flow analysis.

Coordinated multidisciplinary MEP projects with BIM integration and BOQ preparation.

Worked with clients from diverse industries to deliver high-quality, timely solutions - Mechanical Engineer Department of Construction and Technical Affairs · Full-time Sep 2018 – Present 7 yrs 4 mos Ankara, Ankara, Türkiye Department of Construction and Technical Affairs, I was responsible for the preparation of mechanical installation implementation projects, including quantity surveying, cost estimation, progress payments, and technical specification documentation for public buildings within the university's investment program. I carried out on-site inspections and compliance audits of mechanical systems such as HVAC, fire protection, plumbing, and heating–cooling installations. My duties included design verification, contractor supervision, and performance testing. I also developed projects tailored to institutional needs, prepared tender documents via EKAP (Electronic Public Procurement Platform), and performed post-tender technical supervision.

- Research And Development Engineer Dekoplas Plastik Industry · Part-time Nov 2012 – Mar 2025 12 yrs 4 mos Kayseri, Kayseri, Türkiye Worked as an R&D Engineer, focusing on the development of innovative plastic injection-molded products. Designed and improved products with an emphasis on functionality, manufacturability, and cost-efficiency, in line with customer and market expectations. Conducted material selection, mechanical and thermal performance evaluations, and draft angle optimizations specific to injection molding processes. Coordinated with cross-functional teams to develop prototypes, validate designs through testing, and support mass production readiness. Contributed to intellectual property processes by preparing documentation and supporting patent applications for novel designs.

- Production Engineer ASTOR A.Ş. · Full-time Mar 2016 – Aug 2018 2 yrs 5 mos Ankara, Ankara, Türkiye At Astor Transformer, as Core Unit Supervisor, I oversaw the manufacturing processes of transformer cores in line with the weekly production plan. I coordinated the cutting, stacking, magnetic circuit assembly, and insulation of grain-oriented electrical steel sheets, ensuring compliance with quality standards. I prepared daily, weekly, and monthly production reports and provided technical support for production planning and work study processes. I contributed to the prototyping and preparation stages of newly designed core types prior to mass production. I actively supported the coordination of casting, chipless forming, machining, and welding processes on the production line, contributing to overall factory and operations organization.

- Maintenance Engineer Form Sünger ve Yatak Sanayi Ticaret A.Ş. · Full-time Nov 2013 – Nov 2015 2 yrs Kayseri, Kayseri, Türkiye Managed the maintenance engineering activities of form sponge production lines, focusing on both reactive and proactive maintenance strategies. Designed and executed preventive, predictive (condition-based), and reliability-centered maintenance programs to optimize equipment availability and extend asset life. Spearheaded root cause failure analyses (RCFA) to systematically reduce recurrent failures. Implemented CMMS (Computerized Maintenance Management System) for tracking maintenance KPIs such as MTTR, MTBF, and overall equipment effectiveness (OEE). Collaborated with cross-functional teams to ensure adherence to ISO standards and improve maintenance workflows.

Education

- Erciyes University Bachelor’s Degree, Mechanical Engineering 2008 – 2012 Activities and Societies: Active member of the Solar Car Project Team, participating in the design and construction of solar-powered vehicles for national competitions. Involved in the Mechanical Engineering Society and various technical workshops focused on renewable energy and automotive technologies.

Other experience

-

Freelance Mechanical Design Engineer

Self-employed | 2020 – Present

Designing and simulating mechanical systems using ANSYS, SolidWorks, and AutoCAD.

Key projects include filtration systems, hydraulic actuators, and marine gearbox analysis.

Licenses & Certifications

- ANSYS Fluent Specialist – ANSYS Certified Training Feb 2014 – Present

- SolidWorks Professional (CSWP) Aug 2012 – Present