Parametric Design of Polyhedral Dice

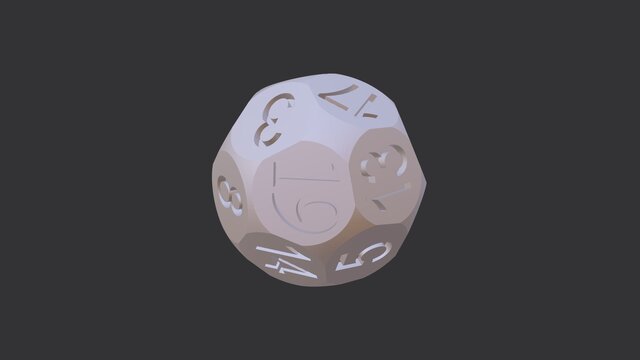

I designed a full set of high-precision polyhedral dice ranging from D14 to D30, optimized for both CNC machining and high-resolution 3D printing. Each die was carefully modeled in SolidWorks with consistent chamfering, pip alignment, and weight-balanced geometry to ensure fair rolling behavior. Individual STEP and STL files were generated for each model to allow seamless integration into CAM or slicing software. The design includes both engineering-grade modeling for production and a clean assembly file for rendering purposes.

This work required a deep understanding of geometric constraints, symmetry principles, and aesthetic balance. The resulting models are ideal for tabletop game manufacturers or collectors seeking custom dice production.

Each die was uniquely configured based on its number of faces, ensuring proper face distribution and rotational symmetry. Chamfer widths and edge fillets were parametrically adjusted to minimize wear during usage and enhance tactile feedback.

Files (7)

License:

CC - Attribution

Learn more

Published