Global rank:

375

/

119,717

Skill pts: 111

1

1st

Gold

1

Finalist

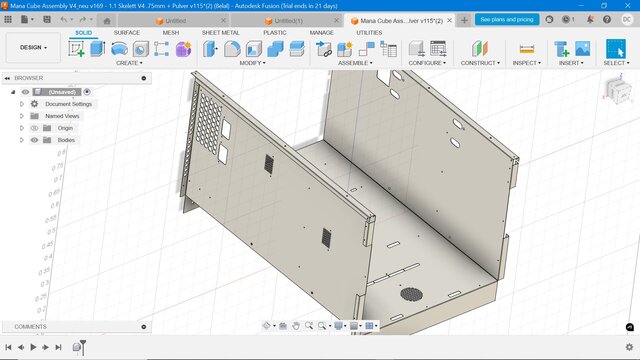

2D and 3D Solid Modeling

3D Mechanical Design

Design for Manufacturing

Fluid Dynamics

Preparing 3D models

About

As an accomplished Mechanical Engineer with a wealth of experience in the field and a mastery of SOLIDWORKS design software, I have consistently demonstrated my ability to contribute to projects with innovative solutions, meticulous attention to detail, and a deep understanding of engineering principles. Throughout my career, I have leveraged my SOLIDWORKS proficiency to enhance product development, streamline manufacturing processes, and bring designs from concept to reality.

Key Skills and Expertise:

SOLIDWORKS Proficiency: With years of hands-on experience, I possess an in-depth understanding of SOLIDWORKS, utilizing its various modules and features to create intricate 3D models, assemblies, and detailed drawings. My ability to efficiently navigate the software empowers me to design complex geometries, ensuring optimal fit, form, and function.

Design Optimization: I am skilled in employing SOLIDWORKS simulation tools to analyze and optimize designs for structural integrity, thermal performance, and fluid dynamics. This expertise enables me to identify potential design flaws early in the development process, saving valuable time and resources.

Parametric Modeling: Leveraging the power of parametric modeling, I create adaptable and flexible designs that can be easily modified to accommodate design changes or variations. This approach enhances the agility of design iterations and accelerates the development cycle.

Collaborative Workflows: My proficiency extends to SOLIDWORKS' collaborative features, facilitating seamless communication with cross-functional teams, stakeholders, and clients. I excel at sharing designs, gathering feedback, and incorporating revisions to ensure alignment with project goals.

Design for Manufacturing (DFM): I have a keen understanding of DFM principles and utilize SOLIDWORKS to design products that are optimized for efficient manufacturing processes. This includes considerations for assembly, materials, machining, and production scalability.

Assembly Modeling: I am adept at creating intricate assembly models, utilizing SOLIDWORKS' tools for interference detection, motion analysis, and virtual prototyping. This skill enables me to simulate real-world behavior, identify potential clashes, and validate product functionality.

Detailed Drawings and Documentation: My expertise extends to producing comprehensive and accurate technical drawings, annotations, and documentation using SOLIDWORKS. This ensures that the manufacturing and assembly processes are well-guided and error-free.

Innovation and Problem Solving: I thrive on solving complex engineering challenges and leveraging SOLIDWORKS to develop innovative solutions. Whether it's creating custom components, exploring alternative designs, or addressing unforeseen issues, my SOLIDWORKS proficiency enhances my problem-solving capabilities.

Continuous Learning and Adaptability: In the rapidly evolving field of mechanical engineering and software development, I am committed to staying updated with the latest SOLIDWORKS features, enhancements, and best practices. My adaptability allows me to incorporate new techniques and tools into my workflow for continuous improvement.

... more »

« less

Key Skills and Expertise:

SOLIDWORKS Proficiency: With years of hands-on experience, I possess an in-depth understanding of SOLIDWORKS, utilizing its various modules and features to create intricate 3D models, assemblies, and detailed drawings. My ability to efficiently navigate the software empowers me to design complex geometries, ensuring optimal fit, form, and function.

Design Optimization: I am skilled in employing SOLIDWORKS simulation tools to analyze and optimize designs for structural integrity, thermal performance, and fluid dynamics. This expertise enables me to identify potential design flaws early in the development process, saving valuable time and resources.

Parametric Modeling: Leveraging the power of parametric modeling, I create adaptable and flexible designs that can be easily modified to accommodate design changes or variations. This approach enhances the agility of design iterations and accelerates the development cycle.

Collaborative Workflows: My proficiency extends to SOLIDWORKS' collaborative features, facilitating seamless communication with cross-functional teams, stakeholders, and clients. I excel at sharing designs, gathering feedback, and incorporating revisions to ensure alignment with project goals.

Design for Manufacturing (DFM): I have a keen understanding of DFM principles and utilize SOLIDWORKS to design products that are optimized for efficient manufacturing processes. This includes considerations for assembly, materials, machining, and production scalability.

Assembly Modeling: I am adept at creating intricate assembly models, utilizing SOLIDWORKS' tools for interference detection, motion analysis, and virtual prototyping. This skill enables me to simulate real-world behavior, identify potential clashes, and validate product functionality.

Detailed Drawings and Documentation: My expertise extends to producing comprehensive and accurate technical drawings, annotations, and documentation using SOLIDWORKS. This ensures that the manufacturing and assembly processes are well-guided and error-free.

Innovation and Problem Solving: I thrive on solving complex engineering challenges and leveraging SOLIDWORKS to develop innovative solutions. Whether it's creating custom components, exploring alternative designs, or addressing unforeseen issues, my SOLIDWORKS proficiency enhances my problem-solving capabilities.

Continuous Learning and Adaptability: In the rapidly evolving field of mechanical engineering and software development, I am committed to staying updated with the latest SOLIDWORKS features, enhancements, and best practices. My adaptability allows me to incorporate new techniques and tools into my workflow for continuous improvement.

Experience

- 3D model with simulation Kunshan Reention Electrical and Mechanical Co.,Ltd · Freelance Oct 2023 – Present 2 yrs 3 mos undefined, Jiangsu, China Create a 3D model and simulation

-

Creat 3D model from 2D using solidworks

https://www.cadcrowd.com/jobs/563-mechanical-engineer-of-special-clamping-fixtures · Freelance

Sep 2023 –

Present

2 yrs 4 mos

undefined, Germany

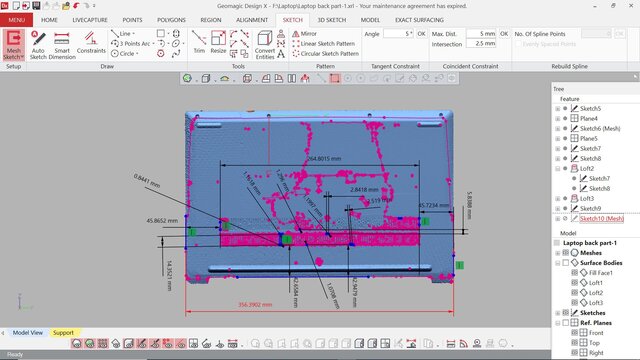

In the world of manufacturing and engineering, the transition from 2D machine parts to 3D has been nothing short of transformative. This evolution represents a complex Machinery parts Project design, production, and understanding of complex mechanical components. The experience of this complex project fascinating journey filled with innovation, increased precision, and efficiency. Here, we delve into the profound transformation from the realm of two-dimensional drawings to three-dimensional models.

1. Digital Elevation:

The journey begins with the digitization of 2D blueprints. This process involves translating traditional hand-drawn sketches into digital formats using computer-aided design (CAD) software. The switch from paper to pixels signifies the first step in bringing machine parts into the third dimension.

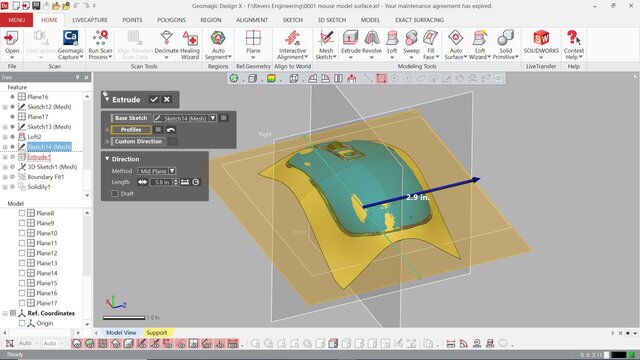

2. 3D Modeling:

The heart of the experience lies in the creation of 3D models. Engineers and designers now have the ability to craft intricate, lifelike representations of machine parts. These 3D models not only capture the part's shape but also its internal geometry, materials, and interactions with other components. This shift enhances visualization, allowing for a more profound understanding of how parts fit into a larger system.

3. Enhanced Collaboration:

With 3D models at the forefront, collaboration among multidisciplinary teams reaches new heights. Engineers, machinists, and quality control experts can share a common visual language, reducing miscommunication and errors. The shared 3D model becomes a central reference point, fostering a sense of unity and clarity in the development process.

4. Simulation and Analysis:

The move to 3D enables advanced simulation and analysis tools to take centre stage. These tools allow engineers to predict the performance of machine parts, identify stress points, and optimize designs before any physical prototypes are manufactured. This predictive capability leads to more robust and efficient products.

5. 3D Printing and Prototyping:

Another profound aspect of this transformation is the advent of 3D printing technology. Once machine parts exist in a digital 3D format, they can be physically realized through 3D printing. This allows for rapid prototyping, cost-effective small-batch production, and the ability to iterate designs quickly.

6. Real-World Accuracy:

The shift from 2D to 3D significantly enhances the accuracy of machine parts. In 2D drawings, certain subtleties may be lost, but with 3D models, designers can account for every dimension and detail. This precision translates into better-fitting parts, reduced waste, and fewer production errors.

7. Lifecycle Management:

The 3D transformation also encompasses the entire lifecycle of machine parts. With 3D models, it becomes easier to track and manage parts throughout their existence, from initial design and manufacturing to maintenance and eventual retirement. This comprehensive approach improves sustainability and reduces downtime.

8. Evolution of Training and Education:

The shift to 3D has redefined how future engineers and machinists are trained. Educational institutions now incorporate 3D modelling and simulation into their curricula, ensuring that the next generation is well-prepared to navigate this dynamic landscape.

In conclusion, the experience of converting 2D machine parts to 3D is a journey that has revolutionized the field of manufacturing and engineering. It has brought about increased precision, improved collaboration, enhanced analysis capabilities, and a more holistic understanding of machine parts' lifecycles. This transformation not only streamlines the design and production process but also paves the way for a more innovative, efficient, and sustainable future in the realm of machine part development. -

Slurry Centrifugal Pump design using solidworks with CFD simulation on ANSYS

Engineering Institute of Technology (EIT) · Freelance

Sep 2023 –

Oct 2023

1 mos

undefined, Australia

I am so happy to design a slurry centrifugal pump impeller using CFD.

It was required to use Solidworks to create a geometry for the volute and impeller and also Import the geometry into Ansys and generate CFD simulation. This project was created for students of the Engineering Institute of Technology in Australia. I successfully completed this project and taught the students about the project. -

Mold Designer

www.francemarplastics.com · Freelance

May 2023 –

Jun 2023

1 mos

undefined, Canada

It was a freelance job on the ▒▒▒▒▒▒ marketplace about mold design,

Please check my profile at the link:

https://www.▒▒▒▒▒▒.com/s/jXE8Nw,

I also work on the ▒▒▒▒▒▒ marketplace, Please visit my profile at the link:

https://www.▒▒▒▒▒▒.com/freelancers/~01326450203ec85e23,

I also work on the ▒▒▒▒▒▒▒▒▒▒▒▒▒▒ marketplace: Please Check My profile link

https://www.▒▒▒▒▒▒▒▒▒▒▒▒▒▒/u/Engrmdbelal?sb=t

Education

- University of creative technology Chittagong Bachelor Of Engineering, Mechanical egineering, A 2017 – 2021 Activities and Societies: null Bacholor of science in Mechanical Engineering

Other experience

- Injection Mold design I have done Injection mold design for many client. Slip casting mold, die casting mold.

Top Designer

Top Designer