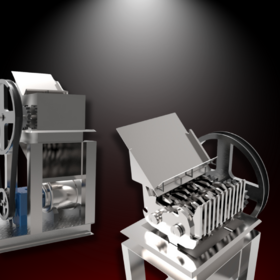

Solid modeling is one of the newer functions of computer-aided design (CAD) and CAD services. It is also one of the more advanced forms of three-dimensional geometric modeling. Any new product can benefit from having a solid model created using CAD software. A solid model shows all the parts of your product in 3D on your computer, and the model is brought to life through angles, lighting, and shadows. A skilled artist can create a model depicting a final product replica. This model can then be revised as the dimensions or specifications of your product evolve.

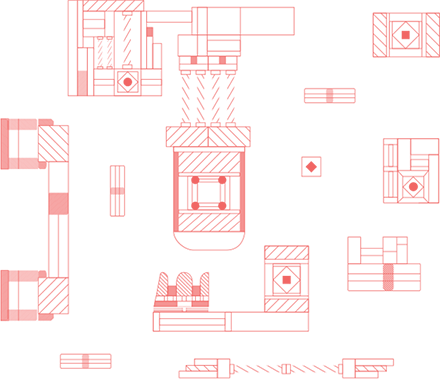

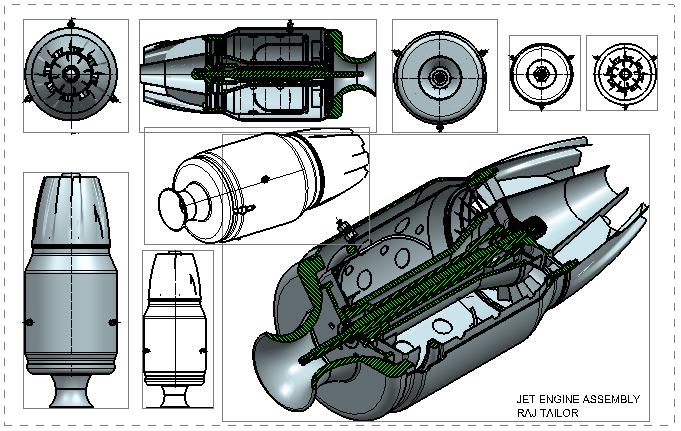

Traditionally, a physical 2D or 3D product model is created using simple materials to estimate the final dimensions. This is often done using wireframes to represent each part of the product. CAD modeling software adds the surface layer onto the wire outlines. This gives the image a solid appearance, and it's how the name solid modeling was derived.

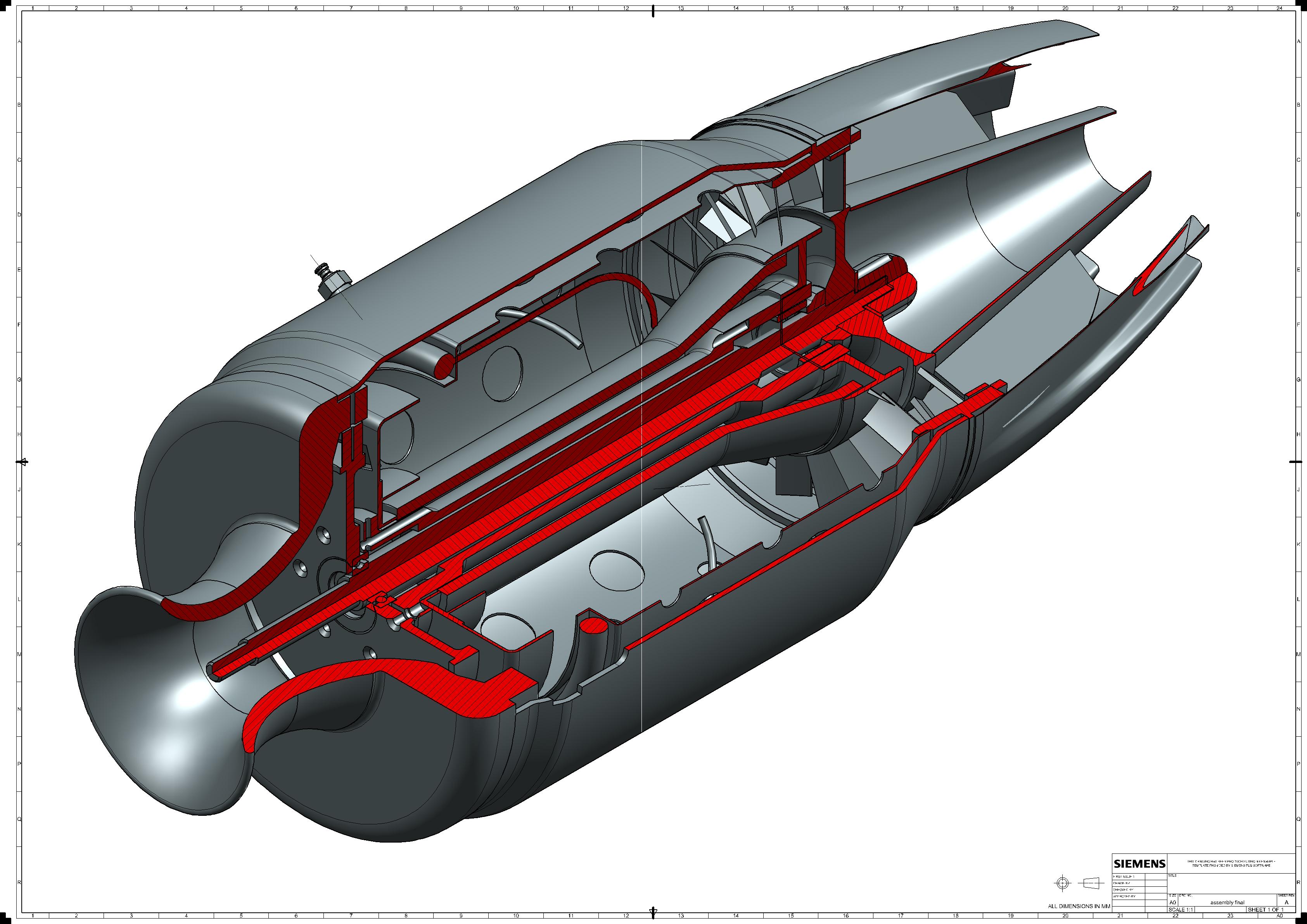

One aspect of solid modeling that makes it so much more complicated than other types of geometric modeling is the need to be as true to the object's physical form as possible in terms of measurements, dimensions, materials, and components. Solid modeling was created as the next step in 3D modeling. Now, a model could represent the physical dimensions of an object and depict how the object will function in the real world. If the software determines that components are misaligned or that measurement tolerances have been exceeded, the designer can make the necessary corrections to ensure the model works correctly.

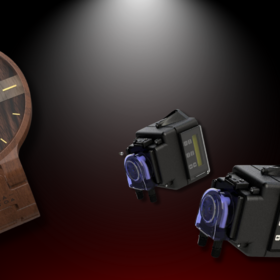

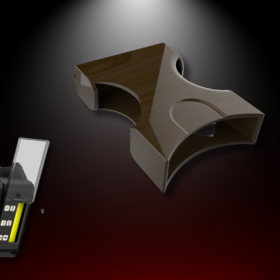

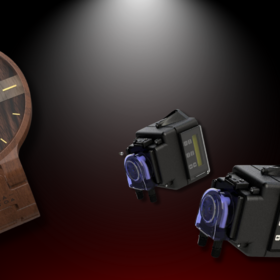

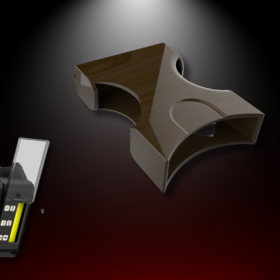

The specifics of the product will also affect the design. The materials used in manufacturing your product must be precisely replicated in the 3D solid model. Every material has a different color, texture, finish, and shine (among other things). Even various kinds of plastic give off a different hue when illuminated. Wood grain may be one of the most complicated materials to replicate in a solid model, but it often has a stunning effect worth the extra effort.

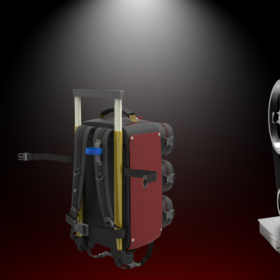

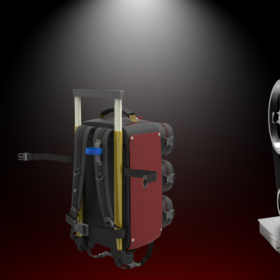

Adding 3D animation to a solid model takes it to the next level and complicates the process. A 3D animation shows precisely how the parts interact and how a machine will work when assembled. Because solid modeling software considers each part of the whole as a separate design component, the model's flexibility is nearly limitless. If there are any changes to the design specifications, the program will automatically render a new version of the part or product when the new specs are entered.

Using solid modeling software has many benefits when designing a new product. The software will automatically perform complex engineering calculations needed in the design-creation process. Solid modeling is also a helpful way to simulate the construction of your new product. You can create variations of your original plan through solid modeling and try out different materials. A solid model can be used to determine the best manufacturing method, what parts are needed, and how well they will work together.

The most significant benefit of using a solid model in your design process is that it will work exactly like the actual product once it is manufactured. If the solid model doesn't look or move the way you want the product to, there is still time to make changes to the design, at even the most minute level. This could save valuable time and money later in the process.

Only to a point. CAD software creates solid models using several different processes. Defining these is probably outside the scope of this article, but as you research solid modeling for your project, here are some of the terms you may run across:

Only to a point. CAD software creates solid models using several different processes. Defining these is probably outside the scope of this article, but as you research solid modeling for your project, here are some of the terms you may run across:

But don't get lost in the technical side of 3D solid modeling. Solid modeling can give you an edge when making presentations to potential investors if you're an entrepreneur or business owner. At times, it can be hard to accurately present your idea in a way that will help your audience visualize the end product easily. But with an accurate, solid model, you can eliminate confusion and present exactly what you're trying to create to those who matter most: your clients.

While initially intended only for machining and assembly,  recent innovations in solid modeling software have expanded the number of industries where solid modeling is used. Solid modeling is used in engineering and product design to get a feel for the product's appearance when it is finished. It is used in architectural design to show the final layout and construction. Solid model mock-ups are created for new medical devices, body parts, and organs in the medical field, making it easier for medical practitioners to plan procedures, treatments, and surgeries.

recent innovations in solid modeling software have expanded the number of industries where solid modeling is used. Solid modeling is used in engineering and product design to get a feel for the product's appearance when it is finished. It is used in architectural design to show the final layout and construction. Solid model mock-ups are created for new medical devices, body parts, and organs in the medical field, making it easier for medical practitioners to plan procedures, treatments, and surgeries.

Some of the industries that have recently begun using 3D solid modeling techniques are:

A solid model is a fast and straightforward way for people to grasp the concept of your design or project. It offers a visual component to your pitch that is superior to a photo or video and will cost you a lot less to create.

Since solid modeling is intricate, you'll want to select from only the best designers. This is where Cad Crowd can help. We have a database of dependable, solid modeling design freelancers from around the world waiting to take on your next project at an affordable price.

Utilizing a Cad Crowd expert for your solid-modeling projects can often be more cost-effective than expanding current staffing levels within your organization. In the long run, you'll save money on software, equipment, and training.

Our freelancers are available for one-time tasks or long-term projects. When you use one of Cad Crowds pre-vetted design experts, you know you’re receiving quality work. In fact, we guarantee it. If the final product doesn’t match your specifications, we’ll give you your money back.

If you want to know more about how it all works, take a look around our website. When you’re ready to get started, send us your project details for your free project estimate.