Global rank:

2,884

/

121,821

Skill pts: 11

About

Mechanical Design Engineer with 20 years of experience in product development for consumer glass packaging and mechanical components. I specialize in designing glass, PET molds, plastic injection parts, machine components, and conveyors. My proven track record includes creating packaging machines for industries such as Food and Beverage, Pharmaceuticals, Home and Personal Care, Tobacco, and Oil and Gas. Proficient in CAD platforms like Pro/Engineer, NX CAD, SolidWorks, and AutoCAD.

... more »

« less

Experience

-

Mechanical Application Engineer

Laxford Industrial Equipment Trading LLC · Full-time

Mar 2021 –

May 2024

3 yrs 2 mos

Dubai, Dubai, United Arab Emirates

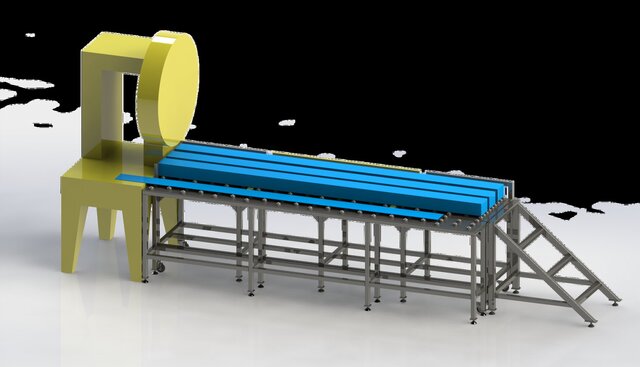

• Designed and developed customized conveying solutions for a wide range of industries, including pharmaceuticals, food & beverage, personal care, cement, and electronics.

• Oversaw installation and ensured alignment with customer requirements.

• Coordinated with international partners (Flexlink, Interroll, Floveyor, etc.) for optimal

solution development.

• Engaged with customers for project planning, proposal discussions, and post-sale

support.

• Promoted and sold technical solutions; performed needs analyses and cost-benefit

evaluations.

• Built long-term client and vendor relationships.

• Negotiated contracts, pricing, shipping terms, and value-added services.

• Managed vendor sourcing, procurement, compliance, and documentation.

• Arranged import/export logistics and maintained accurate shipping records.

• Performed cost analysis and ensured on-time material availability.

• Custom-designed conveyors for diverse sectors

• Led installations & aligned with client specs

• Coordinated with global partners for solutions

• Managed sales, support, and client relationships -

Machine and Tool Design Engineer

Element 26 Engineering LLC · Full-time

Sep 2017 –

Mar 2021

3 yrs 6 mos

Dubai, Dubai, United Arab Emirates

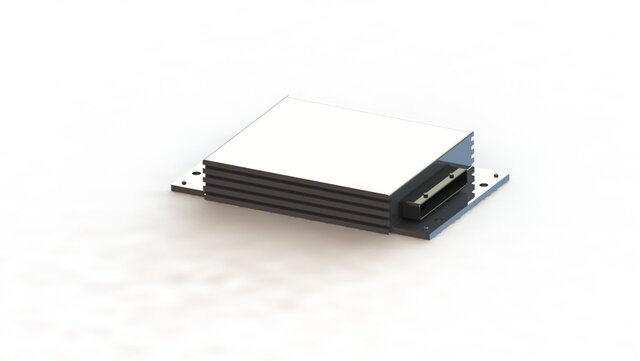

• Designed and developed packaging and conveyor machinery.

• Directed 50+ projects from design to production run.

• Used SolidWorks, NX, Pro-E, and AutoCAD for tooling and machine part design.

• Implemented APQP processes and developed tooling standards.

• Reduced tooling costs while enhancing quality by introducing new solutions.

• Led 50+ machinery projects

• Expert in CAD & 3D software

• Adopted APQP for efficiency

• Cut tooling costs, upped quality -

Glass Mould Specialist

Bangkok Glass Company Limited · Full-time

Jun 2016 –

Jan 2017

7 mos

Bangkok, Bangkok, Thailand

• Enhanced mould design processes, improving productivity by 30%.

• Conducted audits, reduced NCRs, and introduced design improvements.

• Delivered new product developments and quality enhancements ahead of schedule.

• Boosted design productivity 30% -

Mold Design Specialist

SMC Yamamura Fuso Molds Corporation · Full-time

Apr 2006 –

Jun 2016

10 yrs 2 mos

Calabarzon, Philippines

• Designed molds for BB, PB, and NNPB processes.

• Facilitated design reviews and installation support.

• Led preventive actions and performance evaluations with plant managers.

• Designed molds for key processes

• Conducted design reviews -

Product Development Specialist

SMC Yamamura Fuso Molds Corporation · Full-time

Apr 2006 –

Jun 2016

10 yrs 2 mos

Calabarzon, Philippines

• Led concept-to-launch design and process development.

• Created BOMs and cycle time estimates.

• Guided junior engineers, resolved production issues, and ensured project timeline

adherence.

• Conducted trend analysis to drive new product innovations.

• Led concept-to-launch design

• Created BOMs & cycle time est.

• Mentored juniors, fixed issues

• Analyzed trends for innovation -

Mold Designer

SMC Yamamura Fuso Molds Corporation · Full-time

Jul 2000 –

Apr 2006

5 yrs 9 mos

Calabarzon, Philippines

• Produced detailed 3D/2D mold designs.

• Coordinated technical reviews and collaborated across departments to ensure design

integrity and raw material supply.

• Crafted 3D/2D mold designs.

• Led technical design reviews.

• Fostered cross-department collaboration.

Education

- Technological University of the Philippines Bachelor of Science, Mechanical Engineering 1995 – 2000

Other experience

-

Underchassis Mechanic

Inspect, diagnose, and repair vehicle undercarriage components such as suspension systems, steering mechanisms, braking systems, and exhaust assemblies.

Key Responsibilities:

- Inspect, diagnose, and repair underchassis components including: Suspension systems (shocks, struts, springs, bushings)

Steering systems (tie rods, ball joints, rack and pinion)

Braking systems (drums, discs, pads, calipers, brake lines)

Exhaust systems and mufflers

- Conduct routine maintenance and alignment checks

- Identify wear, damage, or safety concerns through visual and mechanical testing

- Perform wheel alignment, wheel balancing, and underbody cleaning.

- Replace defective or worn-out parts and reassemble components.

- Use appropriate tools, equipment, and diagnostic machines.

- Maintain a clean and safe working environment.

- Record service and repair activities accurately.

- Follow safety procedures and manufacturer specifications.

Licenses & Certifications

- Mould Design Engineering Training Nov 2011 – Present

- Basic Mold Design for Injection Molds Dec 2003 – Present