A fabrication drawing is a type of schematic, often used in manufacturing, construction design, and architecture projects. It’s a detailed drawing, showing all of the components in an assembly, whatever that might be defined as in each industry. An “assembly” can also mean a single part in some cases. There is a lot of versatility in how fabrication drawings can be used, how much detail they show, and whether there is only one or many for the same project.

The main areas where fabrication drawings are used are:

The main areas where fabrication drawings are used are:

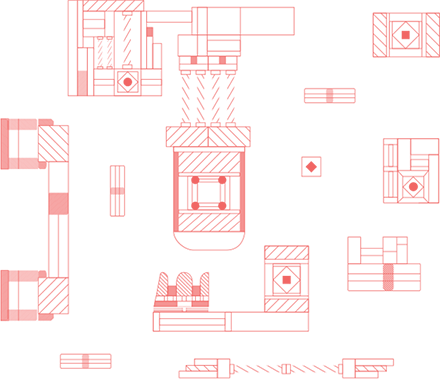

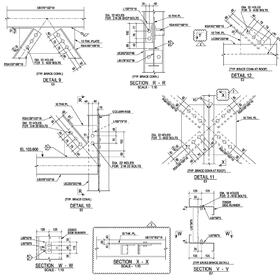

There are three general types of fabrication drawings for any project in any industry:

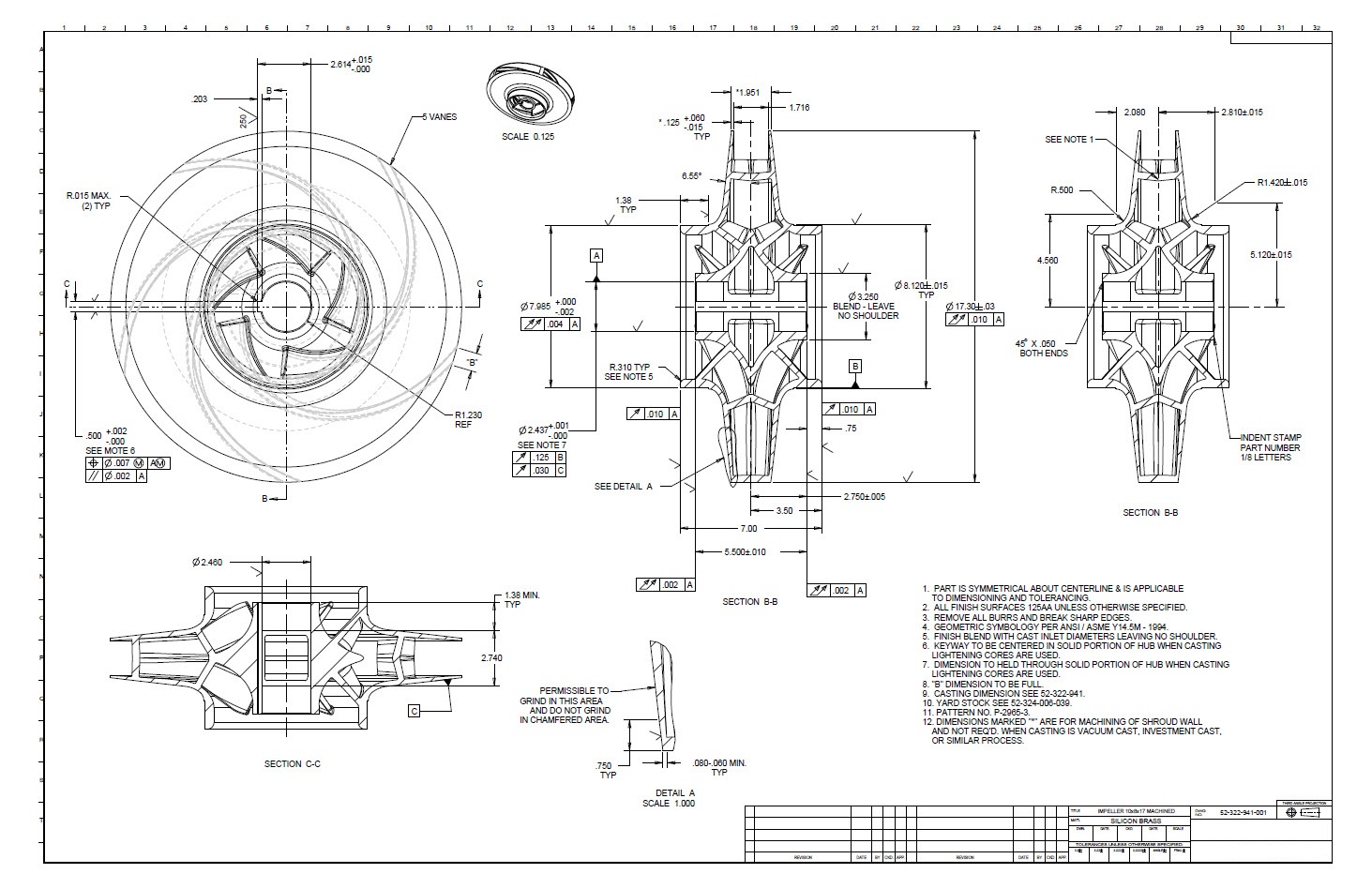

Each type of fabrication drawing gives specifics about what is depicted in the drawing. This includes details about how a part or structure is built, what materials are needed, how it is put together, and how it is installed (if it needs to be). The complexity of the project will dictate how many of these drawings need to be created for any project and whether all three types are necessary. More times than not, all three are used and often involve more than one drawing of all three types to present the assemblies from different angles.

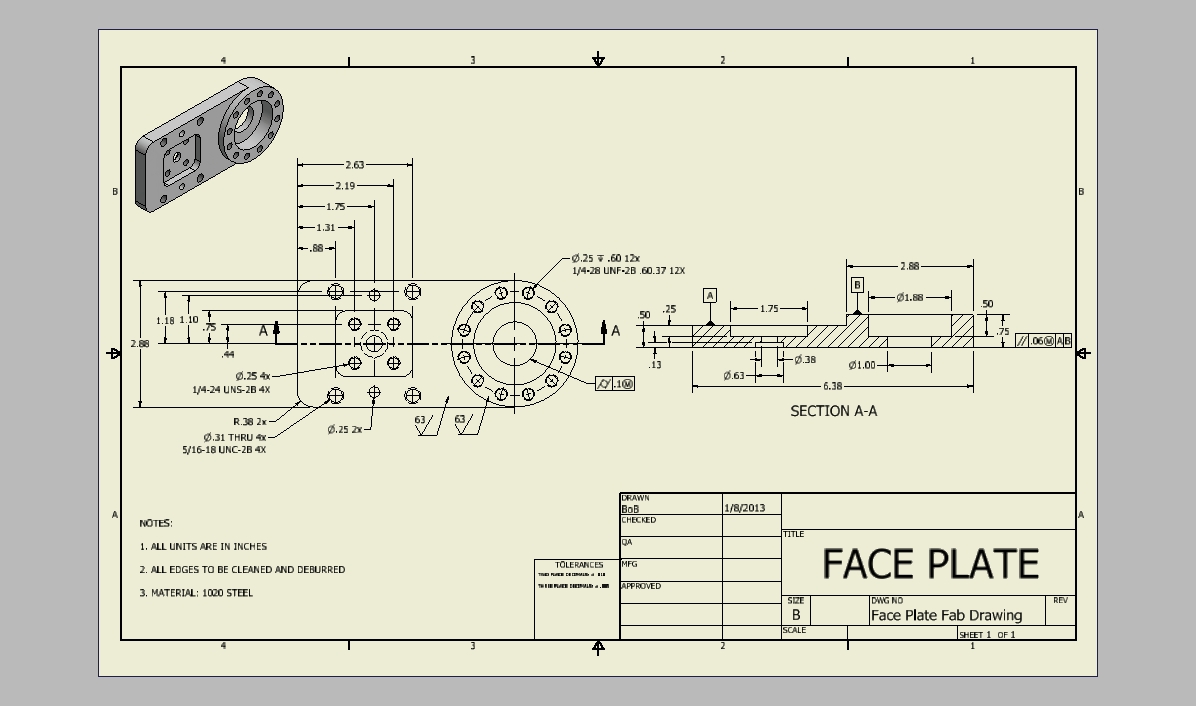

A single part drawing will include information on:

A single part drawing will include information on:

These drawings can sometimes be the only source for this information on a project. If the information is missing or inaccurate, it can cause project delays, which can cost a lot of money to resolve if you’re on a tight deadline. A general assembly drawing will include the following information:

No matter what industry the fabrication drawing is being used in, the information given on the drawing must be accurate and correct. If measurements are off even slightly, they can have disastrous consequences. For example, suppose the measurements listed for a building structure are incorrect. In that case, the architecture won’t be sound, putting anyone who comes into contact with the construction or finished building at risk of damage or collapse that could happen as a result.

The major problems that can arise from wrong or missing information on a fabrication drawing include:

Some would argue that fabrication drawing is better done in a shop environment, where measurements and tooling are more precise, than in a field environment, where mistakes can be made for the sake of efficiency. While both are still viable practices and are still used equally, the real stress of fabrication drawings is accuracy and detail, which certainly favor a shop environment. Fabrication drawings do not necessarily require long periods of time in order to complete, but because they are so precise, the current amount of time should always be allocated to them. Rushing completion in an effort to save time and get things started will likely only result in dreadful mistakes.

There is also debate as to how fabrication drawings should be created. Many designers continue to make them the old-fashioned way, with pencil and paper. As design software advances, though, using computer-aided design (CAD services) to help you create your fabrication drawing can save you a lot of time. Even by-hand fabrication drawers will usually use a CAD software to double check their calculations and dimensions before submitting their drawing for review.

When you work with expert fabrication designers at Cad Crowd, you can expect to receive three types of fabrication drawings. Each type plays an important role in the construction process. They give specifics about how the elements will actually be manufactured, fabricated, assembled, or installed. Depending on the complexity of a project, all three types of drawings may be required and can involve more than one drawing in a variety of views and angles.

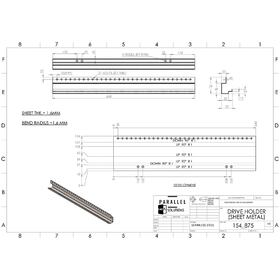

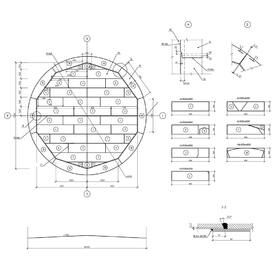

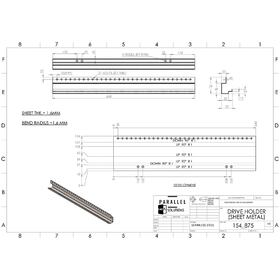

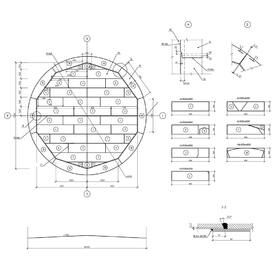

Single part drawings are drawings that show the fabrication details of one part. The information, usually presented on an A4 or imperial standard size 8.5" x 11.5" sheet, contains specific information for the material, cutting, linear dimensions, angular dimensions, weight, etc.

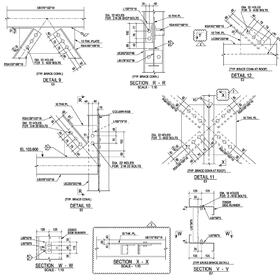

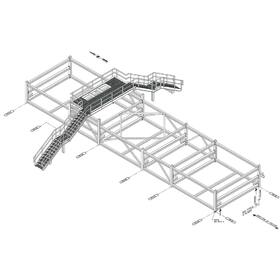

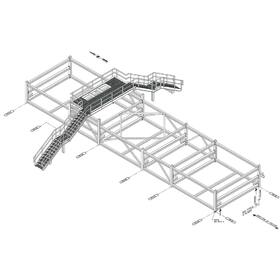

Assembly drawings give information about more than one component and show how all the parts fit together. They usually include instructions, finished lists of the components, and reference numbers. They may also include dimensions, notation, and symbols.

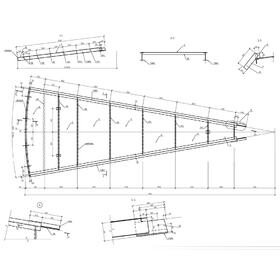

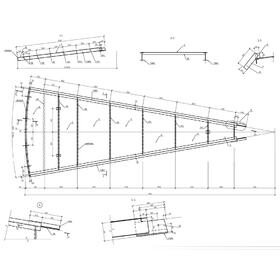

General arrangement drawings show the overall composition of the project. It usually shows the complete model or an extract to convey the intended design in an unambiguous manner, detailing how all the parts fit together and containing multiple drawing angles and views. General arrangement typically includes different projections, such as plans, sections, and elevations, and may be spread across several different drawings.

For the fabrication and construction industry, fabrication drawing is nothing less than an asset. With these drawings, executing a fabrication process perfectly becomes easier. Cad Crowd’s engineers and drafters have been providing qualitative and accurate fabrication drawings to several industries across the world.

We have a database of skilled engineers who are used to handling the latest CAD software and computer programs, to deliver the best of fabrication drawings. They adhere to international standards to make sure that the quality of these fabrication drawings is up-to-the-mark.

Prior to advancements in technology and the ascent of the digital era, preparation of fabrication drawings was a tedious process. It involved a lot of time and energy. Presently, there are still professionals who prefer the traditional method that involves using pencil and paper.

However, engineering and construction demand a great deal of accuracy and perfection. Even the slightest of errors can result in the loss of valuable time, money, and even life.

With CAD and computer software, it is now possible to develop these drawings more effectively and accurately. Even fabrication drawings done manually are almost always checked with CAD software to make sure that the inputs and calculations are correct and of the standard.

Here are some of the significant advantages of CAD fabrication drawings:

Better design quality: CAD programs are an excellent tool for design experts. They help in carrying out design and analysis of a proposed project. Manual designs take a lot of time and cause a delay in the overall process. Human errors such as inaccurate measurements and mistakes due to parallax were also very common with the pen and paper method.

Easy to save and share: Fabrication drawings made with CAD software are easy to save and preserve for future use. It can be edited and printed whenever required. Manual drawings require a lot of space to store whereas CAD shop drawings can be stored and shared through the hard drive, USB pen drive, or cloud.

Faster modification: The modification of CAD shop drawings is easy with the variety of tools available in CAD software. As compared to the traditional method, correcting any error is much quicker.

Acts as a communication link: Apart from everything else, fabrication drawings play a vital role in connecting prominent professionals in the project, such as architects, engineers, fabricators, contractors, and more.

The advantages of preparing fabrication drawings with CAD technology are great. With CAD technology, it has become easy and quick to prepare fabrication drawings. They can be saved and changed any number of times and shared by all concerned at the same time. They can also be revised and reviewed repeatedly.

However, preparing fabrication drawings with this method requires expertise and experience. The drawings must comprise exact information, and since they are followed for working, errors in them can lead to faulty fabrication and installation.

Cad Crowd has several highly skilled professionals who put effort and passion into their work. At Cad Crowd, you will be connected with top-notch freelance specialists that can handle a variety of drafting and engineering projects with ease.

Cad Crowd’s fabrication drawing services will also help you ditch reworks in your project, cut back on cost, and boost productivity. Whether your project is small budget or large scale, our expert freelance CAD drafters, designers, and engineers are ready to be at your service with their high precision drawings, quick turnarounds, affordable rates, and constant availability.

Poorly written work instructions, wrong operating procedures, incorrect or unfinished fabrication drawings, and blueprints are just some of the things that can jeopardize all the work put into a project. The inclusion of structural design services can mitigate these risks. Here are some of the scenarios where this can happen:

A fabrication drawing is not something that can be done by just anybody who knows how to use a computer. Generally speaking, for a fabrication drawing to be done, a person would need to be skilled in drafting and understand the language of fabrication drawings. He should also understand the standards and have a background in engineering and the use of CAD programs.

That’s why you can’t just hire any CAD freelancer for your project. Choose from one of our pre-vetted engineers and drafters to execute your project and provide you with fabrication drawings that are 100% accurate and delivered right when you need them. Cad Crowd freelancers work closely with each client to ensure that all drawings are up to specifications and free of errors, delivered on time and within their budget.

If you don’t have access to a shop, or don’t have the right equipment or space to create fabrication drawings (or simply don’t want to do it), let us help. Cad Crowd has an international database of freelance fabrication drawing designers who have the knowledge, skill, and expertise to assist you in creating the fabrication drawing you need to move on to the next step in the process.

If you have a design idea, but don’t know how to get it onto paper, hold your own engineering design contest and let our fabrication drawers create the first draft for you. This way, you can even get suggestions on sizing and materials to use for the construction of your design. You only have to pay for the winning design and get to keep the rest of the designs, as well.

Contact us for a free confidential quote on your fabrications drawings project.

What sets Cad Crowd apart is its global network of skilled and experienced professionals you can choose from. We will connect you with the right drafter to take on your project. All our freelancers have been carefully and thoroughly vetted, so you can rest assured you’ll be working with only elite professionals.

Instead of settling for an average company to handle your fabrication drawings, or spending hours sifting through hundreds of CVs and applications, choose from one of our qualified top-ranking CAD drafters to get you to job done fast, accurately, and to your project specifications.

We stand behind our freelancers, and we will ensure that you are satisfied with the services they provide. Contact us today for a free no-obligation quote and get connected with a true fabrication drawing expert.