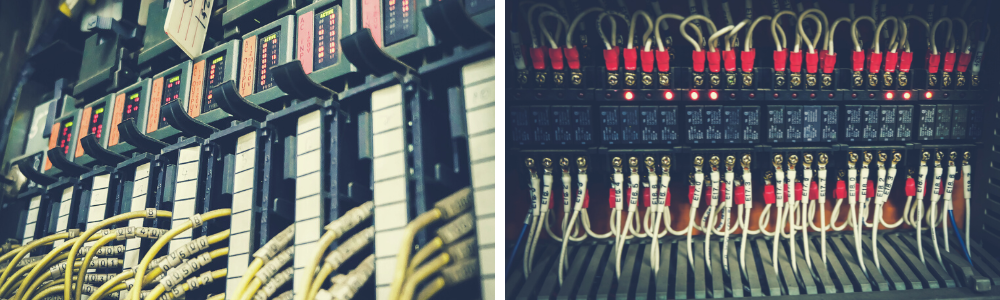

The manufacturing industry is a valuable aspect of modern-day life. Without mass production, we would still rely on individual tradespeople and artisans to create goods. When the first programmable logic controllers (PLC) were developed, it was an incredible innovation for manufacturing. PLC technology and PLC services implement programmable automation that manufacturers consider essential.

PLC programming is a specialized skill that is challenging to learn and requires courses and training. Programming mistakes are costly, resulting in production downtime and potential damage to equipment and personnel. A high-quality PLC programmer is critical to the operational success of the manufacturing setup. Finding a skilled PLC programmer for your project can be difficult, and you must also consider reliability, authenticity, and cost when choosing an independent contractor. In addition, companies have significant privacy and intellectual property rights concerns.

PLC programming companies that specialize in PLC programming are also an option. Finding an organization with consistently high-quality work that recognizes your company's unique needs is the problem. Using a PLC programming company is only helpful if they will customize something appropriate for your circumstances.

Consultants and companies also have payment terms that vary by the charge per hour, project, or retainer. Creating satisfactory contract terms, such as turnaround time, accountability, and file revisions, must be considered. Some consultants and companies make that process more costly and involved than it should be.

Luckily, we've made the process easier and safer for you at Cad Crowd. Our database has thousands of vetted PLC programming designers, engineers, and designers with different backgrounds and expertise. Once you select the best freelancer for your scenario, our procedures protect your privacy and intellectual property rights. If required, our network of patent attorneys can also help you through the patenting process.

Bringing your project to Cad Crowd and working with our designers and engineers is easy, and there are a few simple steps from start to finish.

The first thing you need to do is request a free quote. There's just one form to fill out, and it doesn't take long. Please tell us about yourself and provide the details of your project. The more complete your answers are, the more accurate the quote will be.

Once you're requested a quote, depending on your needs, we may recommend specific professionals to meet your project needs. We can recommend a freelancer from our talent pool for hourly work if you need ongoing assistance. Alternatively, you can take the private project approach and initiate a conversation with a PLC programmer through our private project option. If you want to review numerous design options for your project, then a design contest is your best option. These contests attract a variety of entries and provide a preview of what the entrants are capable of designing. Once you've considered the submissions, select the best freelancer for your scenario.

Once you find a professional you are confident in, make sure you can communicate efficiently. While skills and experience are critical, communication is as well. Ensure that you and your PLC automation programmer are on the same page for a positive result.

After you've chosen a freelancer to take care of your PLC programming and automation needs, wait until you receive the finished files, review them, and request revisions if necessary. Remember that communication is critical when working with a freelancer or independent contractor—the clearer and more concise the message, the better the result. Choose someone with the background and skills to communicate with you effectively.

Businesses utilize freelance PLC programming specialists, professionals, remote workers, and independent contractors. Choosing a well-suited freelance PLC automation services specialist for your project offers significant benefits.

Several options are available when you require a specialized skill for your business. One option is to learn the skill yourself, and learning PLC programming takes time, resources, training, and technical expertise. The programming systems in manufacturing today are very specialized.

Another option is for your company to hire a full-time programmer. Job performance, behavior, and reliability must be regularly monitored. While this can be beneficial, retaining a skilled employee who meets expectations is costly. Alternatively, hiring an experienced freelancer for PLC Programming and automation simplifies the process. The programmer will have the expertise required to turn the project around in less time than it takes to find an employee.

The project cost is also significant for most organizations. Hiring a freelancer for projects can offer substantial savings over hiring a traditional full-time employee. Cost savings are possible because you only pay for what you need when you work with an independent contractor. Outsourced project costs are often more affordable than the annual cost of hiring a full-time employee.

One benefit overlooked when considering a freelancer is the possibility of learning something new. Machines and facilities are more advanced and automated than ever before. Working with a freelance PLC programming specialist allows you to utilize their experience, learn, and create efficiencies.

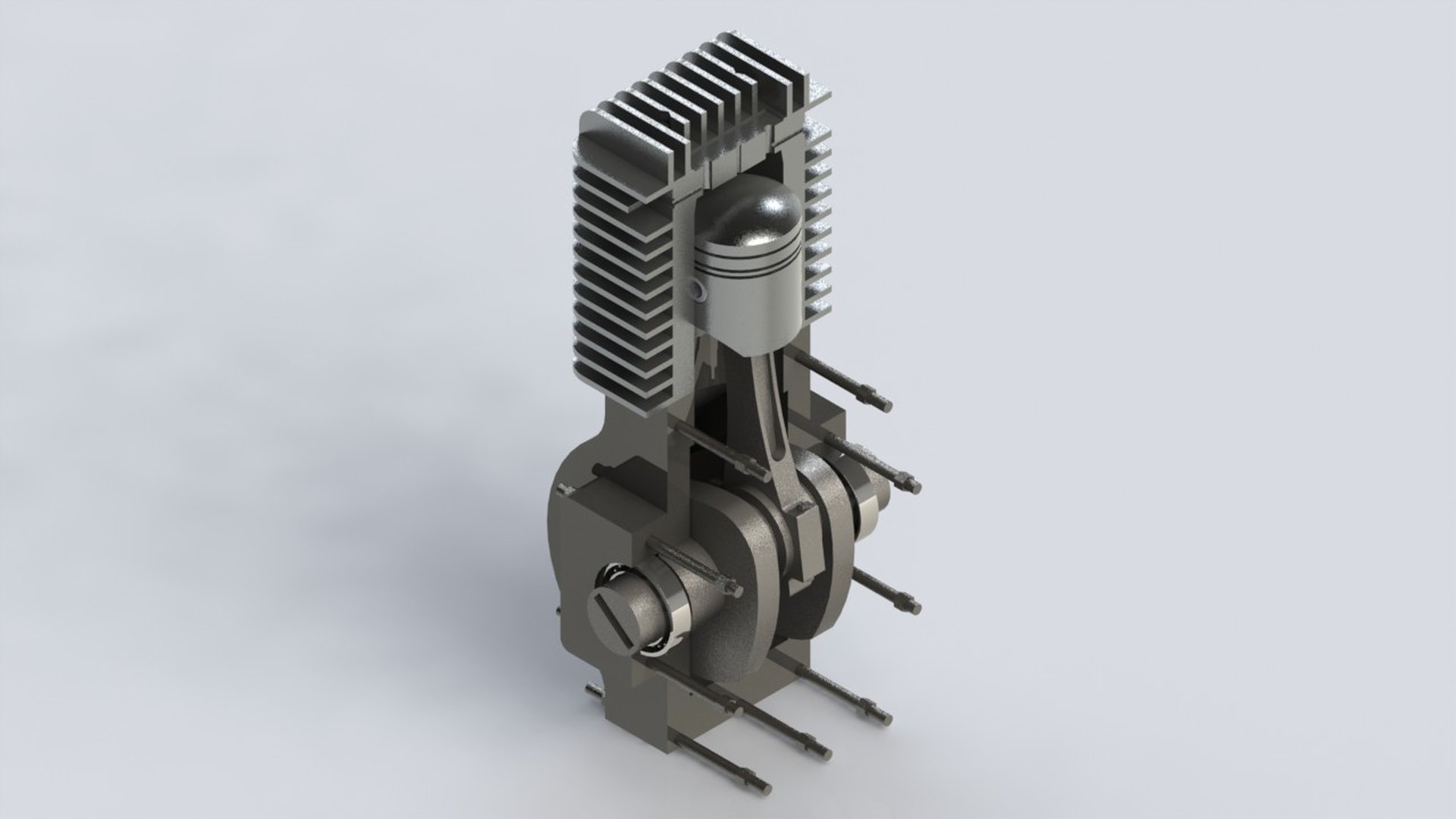

PLC was developed for General Motors in 1968, and while some industrial automation was already in use, it wasn't easy to modify. If a part's design were changed, the machines would have to be changed. The earlier relay logic systems meant a physical modification of the machine and a high chance of failure. PLC technology made it easier to adjust and modify the system, which resulted in less downtime, faster adjustments, and more profitable production.

The auto industry has developed significant new manufacturing technologies on more than one occasion. It's no coincidence that the auto industry drove the development of PLC technology. The profit margins and large development budgets in the auto industry during the 1960s and 70s were a force for progress in manufacturing. Modern manufacturing as we know it would not exist without PLC.

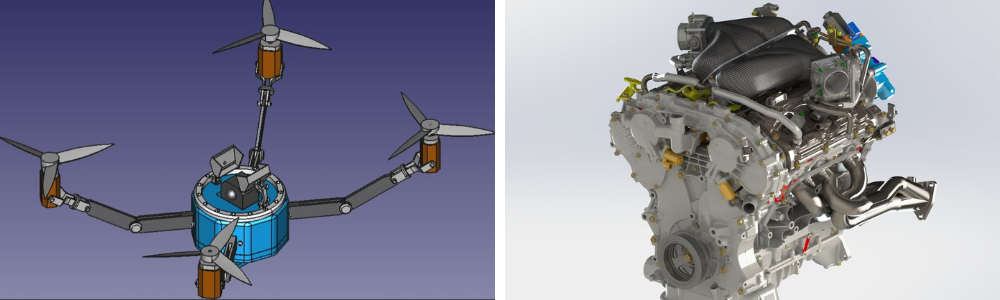

Today, PLC can be found in virtually every automotive manufacturing stage. PLC plays a critical role, from assembly line setups to electrical components and spot welding. Can you imagine employees trying to maneuver and set large parts on the assembly line? There would regularly be mistakes, delays, and injuries. Human efforts can't compare to what PLC can do in an assembly line setting. Cad Crowd offers automotive design and engineering services that assist organizations in revamping concepts and developing new concepts.

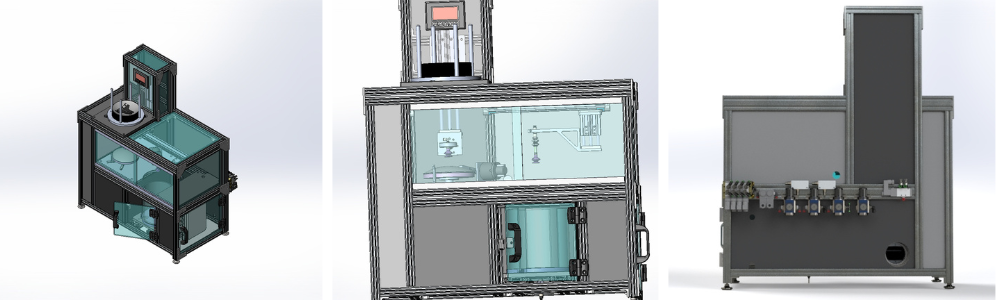

PLC is also an essential part of the pharmaceutical industry. PLC industrial automation services in this industry prevent employees from handling tiny pills and containers. It would take an unbelievable amount of time if billions of capsules were counted and packaged manually. Employees can't keep up with a quality PLC automated assembly setup. In a pharmaceutical setting, it also minimizes waste and reduces potential theft. Cad Crowd offers medical device design services to help companies redesign existing packaging and bring new products to market.

PLC is used in the food and beverage industry to automate processes such as bottling. For example, imagine an operator at a facility overseeing the flow rate to ensure that bottles are not overfilled or underfilled. Manually operating equipment is inefficient, inconsistent, and costly, resulting in poor-quality finished goods. In addition to PLC programming, Cad Crowd offers food & beverage packaging design services for companies.

If you're new to PLC, it is best to speak to a PLC programming specialist, as it's prevalent in many manufacturing industries. Independent contractors or an employee from the company installing the equipment can assist in your understanding and be valuable if you need help choosing a programming language.

A handful of widely used languages do not cross over ideally between different machines and models. The original Ladder Diagram system was intended to be used by machine operators with little or no programming experience, and it's still in use today. Other PLC languages include sequential function charts, function block diagrams, instruction lists, and structured text.

PLC technology can quickly make your manufacturing process faster and more efficient. Automated equipment programs will produce high-quality finished goods that can be rapidly and consistently produced. However, finding a PLC programming designer with excellent programming skills can be challenging.

If you need a PLC Programming and Automation specialist for a project or assistance with other manufacturing services, choose Cad Crowd. Our talent pool is continually growing, and our procedures protect your privacy and intellectual property rights. Get the process started by requesting a free quote today.