Computer Numerical Control (CNC) is a subtractive manufacturing technique used to rapidly create end-use parts and prototypes from a wide array of materials. Milling and tooling can be completed in a matter of days instead of weeks. With Cad Crowd's CNC machining and prototyping services, you'll get access to our network of leading U.S-based rapid manufacturing companies.

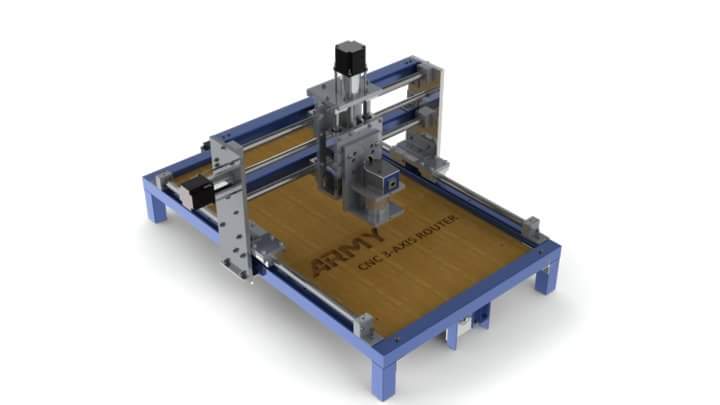

CNC manufacturing uses a high-speed cutting machine to remove material from a block or a pre-existing part, much in the way a sculptor removes material from stone or wood. CNC as a manufacturing process is fast: production runs can be completed in just days that would take weeks in conventional manufacturing. Unlike more limited 3D printing technologies, virtually any engineering material can be machined. While additive manufacturing allows for more flexibility in terms of design, CNC allows for tremendous flexibility in materials.

The greatest advantage of CNC Machining though is its extreme accuracy. The computer-controlled machines are able to achieve unparalleled levels of detail with incredible speed. It is an ideal rapid manufacturing technology for high tolerance requirements where specifications have to exact. Size is not an object, and both large and small parts can be easily created. Because of the wide range materials, high level of detail and good surface finish, CNC is ideal for creating prototypes for functional tests, presentation models, or short runs of end-use parts and tools of almost any size.

Because of the durable materials available in CNC, it can also be used to create master patterns for casting with a higher degree of accuracy and a longer lifespan than those created by SLA. If you need a casting pattern that will last, CNC is a great way to go.

A great advantage of CNC Machining is the potential to use virtually any engineering material. Common materials include:

Ready to start manufacturing? Get a quote now from the best CNC machining and prototyping companies in the United States. And make sure to patent your invention. Use our Patent Attorneys Search to get all the help you need protecting your intellectual property.

Looking for expert CAD designers? Our on-demand CAD design services will connect you with leading CAD designers, drafters, and 3D animators. Get an estimate today.