In modern design and manufacturing services, there is a range of common practices that are used to improve efficiency and a business’s ability to compete. One such process that has existed since the 18th century is industrial design.

In this article, we look at exactly what industrial design is and why it’s important for the creation of new products and prototypes. First, we explore the basic definition of this process. We then look at the advantages it provides for the product lifecycle.

What Is Industrial Product and Prototype Design?

To start, you must have a clear understanding of what this term means and its history. This is not a new process. As the name would indicate, industrial design services first emerged during the industrial revolution of the 18th century.

In Great Britain, during this period, industrial manufacturing emerged on a larger scale, as did the urbanization of the country. This changed people’s habits and required a new way of thinking for product design and production—hence the birth of industrial design.

A Basic Definition of Industrial Design

“Industrial design is a process of design applied to products that are to be manufactured through techniques of mass production.”

This is the basic definition of industrial design. It is design for a large scale of manufacturing. In ages past, design was completed on a much smaller scale. Businesses would design and produce individual products in relation to customer demands. Items would be bespoke and production times would be longer. As time progressed, this method of design and production was no longer feasible for businesses as manufacturing grew.

RELATED: Interview Questions to Ask Freelance Industrial Designers

Industrial design is generally kept separate from the actual manufacturing process—this allows designers to fully concentrate on the product itself and ensure that it is optimized for customer experience. Industrial design specifically deals with form and function. It looks at how the product connects with the end-user and their environment. The idea is to create products that are usable, effective, and provide a pleasing user experience.

This process often overlaps with freelance engineering design—this is because the industrial designer only concentrates on the shape and form of the product. Any mechanical elements or electrical parts would be designed by another person or department.

Industrial designers have a wide skillset. First and foremost, they have excellent creativity and imagination. They must be able to produce interesting and usable designs that customers would enjoy.

Secondly, industrial designers often draw from market research to enhance their ideas. They may look at statistics, trends, and customer feedback to ascertain what works and what doesn’t. This information is ultimately utilized to create products that put the end-user first.

Industrial Product Design

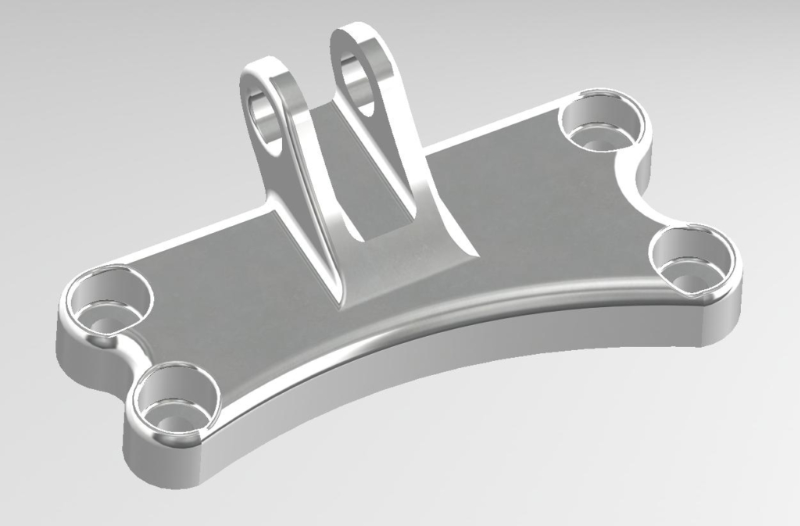

Now, we can look at the specifics—both product design services and prototype design. Industrial product design deals specifically with the product itself. An industrial designer may employ different design methodologies during the creative process. Furthermore, they may complete extensive research on competing products and common design elements. Common elements of industrial product design include:

- Overall shape and size

- Location of specific details and features

- Colors, texture, and surfaces

- Product usage

- Choice of materials

- Point of scale

All of these features are designed with the end-user in mind. This is the whole premise of industrial design—to create products that are suitable for end-use. Functionality, form, and usability are key aspects of this process. After this, the product design would then be translated into a prototype and finally translated into an item that can be manufactured on a mass scale.

Industrial Prototype Design

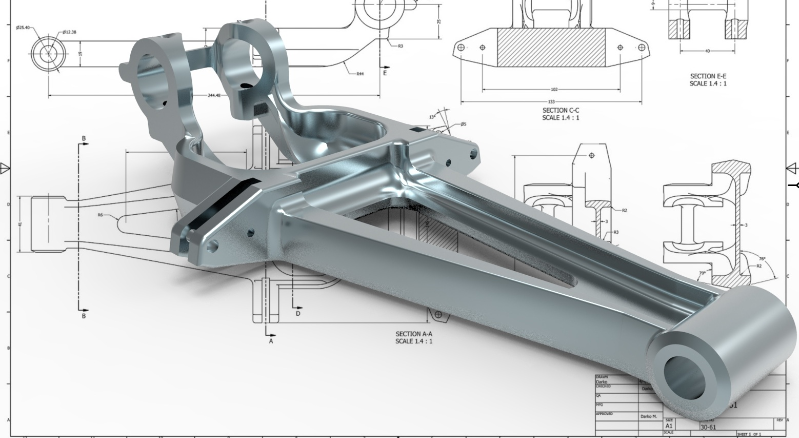

Prototype design engineering involves creating a draft of the product once it has been designed. Prototype designers and producers take the information provided from the initial design stage and use this to create a working version of the item.

Ideally, during the industrial design process, the designers should have listed particulars such as scale, shape, dimensions, and form. The prototype designers can simply look at these details and effectively design a prototype.

The prototype should emulate the aesthetics and ergonomics of the product design. It should be accurate and give a clear representation of the designer’s vision. Furthermore, it should be usable to some degree and allow other teams to draw information from to test its functionality and viability.

Creating prototypes is an integral part of the industrial design process. Without effective prototypes, businesses could release poor products into the market. Alternatively, they could design products that are not suitable for mass manufacturing—this would ultimately lead to delays in product releases and increased business costs. Try using a rapid prototyping service for effective results.

How Can Industrial Design Improve Product Development?

As discussed above, product design involves specifically designing items before they are manufactured. Traditionally, the product and prototype design stages can overlap. For example, the design team may create a product, which is then translated into a prototype. During the prototype stage, problems could arise, which would then be translated back to the design team to solve.

This is why industrial design can improve both product and prototype design. In the following sections, we have listed some of the main benefits of industrial design for product development. We look at innovation, production times, variety, and ergonomics, for example:

Ensure Products Are Released to the Market Effectively the First Time

New product launches must be rolled out effectively and without a hitch. Furthermore, the product itself should be immediately ready for customer use. In addition to this, a new product should effectively be perfect. It shouldn’t have any defects or glaring issues.

Freelance lighting fixture design services understand this. They utilize research, trends, and customer habits to ensure that products are as perfect as they can be. Any potential issues are addressed during the design process. This ensures that the product release runs smoothly.

Why is this important? It positively portrays the business. If you continually release sub-standard products that have poor usability, customers will become skeptical. In addition to this, your reputation will decline and sales will ultimately suffer.

Alternatively, if you become renowned for releasing amazing and functional products, the opposite will happen. First impressions matter for product releases, and this is facilitated by industrial design.

Ensure a Consistent Message and Use of Company Branding

Part of an industrial designers’ role is to incorporate company branding, ethos, and messages into the products. They understand how to do this in a positive manner that doesn’t affect the usefulness and desirability of the product itself.

Ensuring the business message is consistent and branding is used effectively is a highly important marketing tool. It ensures that customer brand awareness is raised and that these high quality and usable products are associated with the company.

Reduced Production Times

As industrial designers hone their skills, they can produce designs quickly. Using their knowledge of ergonomic methods, they can quickly identify features and parts of the product that will work and enhance user experience. Furthermore, they can reuse common methodologies and practices for multiple designs.

Once the basic knowledge is there, it can be used time and time again. This ultimately results in an effective design process. Moreover, it leads to reduced production times from the design stage, through to manufacturing, marketing, and sale.

Offer a Greater Variety of Products

When brainstorming new ideas and product designs, industrial designers often have multiple ideas floating around. This design process encourages creativity and pushes individuals to think outside the box. Ultimately, this gives a design engineer a greater variety when developing new products.

Using other design processes could result in a narrow set of parameters that limit creativity, and the ability to produce multiple product versions. During the initial sketching phase of industrial design, however, hundreds of potential ideas could be thrown into the mix.

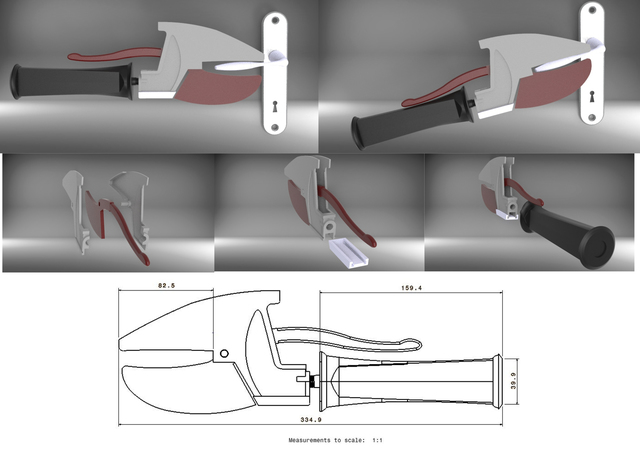

Create Ergonomic Products that Meet Customer Expectations

This is the main point of industrial design—to create products that provide a favorable end-user experience. If you can do this, your business should remain competitive and build a reputation for well-made, enjoyable products.

Industrial design deals specifically with usability—tool design services can assess a product and look at how a customer would interact with it and what constitutes an enjoyable experience. Designing for functionality provides huge benefits for the reputation of the business. Moreover, it ensures that you can create a fantastic array of products that customers will want to purchase.

Provide Greater Flexibility for Manufacturing

As we mentioned above, industrial design is kept separate from the manufacturing process. Products are designed for usability, not for manufacturing—this is a different design ethos and is used in different circumstances. That doesn’t mean that industrial design cannot contribute towards effective and flexible manufacturing.

Industrial design encourages cooperation between the design team and the manufacturing department. The two entities can relay ideas back and forth with a common understanding—a common goal of creating usable products.

For example, the manufacturing services team may require alterations to be made to the design due to its ability to be produced—they may not have machines capable of producing the exact specifications. The two teams could discuss such an issue and create a solution that doesn’t compromise the end-user and their enjoyment of the product.

Discussions and teamwork like this are mutually beneficial. Both the design and production departments will expand their viewpoints and knowledge, all for the betterment of the company and products.

Allow for Quick Design Changes to Meet Changes in Circumstance

Often in the product lifecycle, changes may have to be made—this could be for several reasons. For example, customer expectations and requirements may change. Alternatively, changes in laws and regulations could require your business to alter how they manufacture products or operate.

This type of design ethos allows you to react to changes like these and understand exactly how this would affect the customer and their interactions with the product. If quick changes are needed, the design team can look at the ramifications of said changes—will it provide a negative experience for the user? Will the product still provide the same level of enjoyment and functionality?

Without such an approach to design, any changes made could have far-reaching consequences. This could lead to a failure of the product as customers become disenchanted. Industrial design allows for quick and effective changes to products, without any backlash.

Create an Effective Product Lifecycle

In modern industrial design, the designers usually work as part of a multi-disciplined team. This could include freelance electrical engineering services, project managers, marketing professionals, and strategists, for example. Using this “user-first” design methodology allows the designer to easily interact and cooperate with these other team members.

Interoperation between team members and departments is vital for the success of a business. By using industrial design methods, teamwork is encouraged, and the overall product lifestyle is improved. Understanding the product and its usability is vital in so many aspects of the business. Moreover, by putting the user experience first, different departments can cooperate to realize the same goals.

How can Industrial Design Improve Prototype Development?

Prototypes are preliminary versions of a product. A prototype is essentially the draft version of a product before it enters manufacturing. Prototypes are created to test the viability of products and to see how the designs translate into real-life situations with real materials.

This is the stage of a product life cycle where any design and production issues are highlighted. For example, a prototype could be created and the material used may not be suitable, or it could be deformed. The errors would be referred back to the drafting and design service who would look at alternative materials and try to rectify the issue. There may be several back-and-forth exchanges between the design and prototype teams before the product is ready for manufacturing.

In the paragraphs below, we have listed the main benefits that industrial design can provide for the development of prototypes.

Allow for the Creation of a Greater Range of Prototypes

One of the main blocks during the prototype stage is having a limited variety, and only being able to produce a small range of working designs. Why is this an issue? Because it means the prototype team only has limited resources to work with – this could ultimately mean more time spent working on a single design, and trying to iron out issues with it. Furthermore, it does not give the prototype team as much ability to react to customer changes, new product versions, or different product variants.

By using industrial design, the prototype team can quickly and effectively adapt their models. If the freelance medical device designer has included necessary features like measurements, materials, and scale, the team can then translate these specifications into a working prototype. Moreover, they can re-use those elements to create different varieties/versions of the design.

For example, a design team has developed a new chair made from recycled plastic. A prototype is required to test the comfort, stability, and weight load of the item. During the prototype stage, the design team could create several versions of the chair with different materials or a different colored back.

What does this mean? It means the end product can be tailored so that it is usable and fit for purpose and gives the customer the best possible experience through the efficient creation and testing of multiple prototypes.

Quickly Eliminate Errors and Potential Design Issues

This thorough and functional approach to design also helps eliminate errors when developing prototypes. During the design stage, the usability and function of the product are considered. Therefore, the product engineering service should pick out potential flaws before the product even reaches the prototype stage.

In our chair example, during the design stage, the developer should have considered comfort—can you sit on the chair for long periods without sustaining aches and pains? This comfort factor would be relayed to the prototype developers. Identifying features like these during the design stage ensures that time is not wasted creating unsuitable products that have glaring faults.

The prototype team would not have to waste time creating a handful of different chairs, only to find out that 99% of them were uncomfortable to sit on and caused back pain.

Allow for a Smoother Transition to Further Stages

During the product life cycle, each stage of the process should transition smoothly. Different departments and teams should be able to communicate effectively with minimal effort. Moreover, the product should translate into different areas of the business without issue.

RELATED: Sustainable Product Design Tips for a Healthy World

Industrial design facilitates this during the prototype stage. As the design is approached from an ergonomic point of view, the prototype team should be able to develop a model that can be translated easily into a manufacturing process.

Improve Your Business Processes Today and Employ Industrial Design Methods

We hope you have found this article useful. Businesses need to understand the different processes and methods they can employ, including hiring CAD drawing services. Having an open approach to business practices will allow you to evolve and react to changes in industry and customer requirements. Furthermore, you can ensure that your business is future proof and remains competitive in increasingly difficult markets.

Industrial design is a tried and tested design process that has been used for over a century. If you want to create an efficient product lifecycle that allows your business to create effective products for the end-user, it is certainly a process to consider. As you can see from the benefits above, industrial design has many positive ramifications and can improve businesses a competitive edge.

If you need design assistance, remember that Cad Crowd can connect you with experts in various fields. We work with thousands of skilled designers who can offer their services, including industrial design. Find out how it works or get a quote today!