During a product’s design and development lifecycle, the time for prototype generation will inevitably come. Traditionally, this process has been both time-consuming and expensive.

Prototype machined parts – even if created on a CNC machine tool – have a low benefit-to-effort ratio since all of the programming is done for potentially just a few parts (hence the time factor). The parts also cannot be produced with the economies of scale that are typically realized by production operations (the cost factor).

In the case of parts that are intended to be molded (e.g., a cell phone case), there is also the time and expense involved with creating prototype molds that would not be robust enough to maintain production over the entire product lifecycle. With the evolution of CAD technologies (in particular, 3D model generation), a set of processes has been developed to substantially reduce the time and costs associated with traditional prototyping. These processes are generally categorized under the umbrella term “rapid prototyping.”

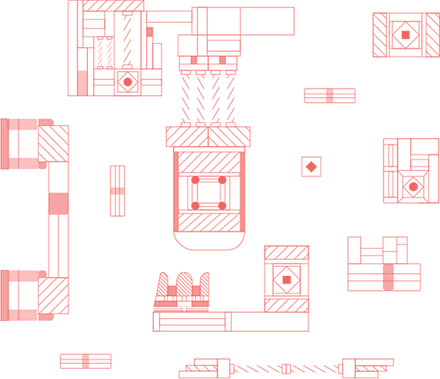

Rapid prototyping involves swiftly fabricating a part, model, or assembly through the use of CAD. Typically, the prototype is created using additive manufacturing or 3D printing technology. Rapid prototyping processes and 3D printing use 3D models generated via CAD programs (such as CATIA, SolidWorks, and Siemens NX).

A central component of rapid prototyping is 3D printing. 3D printing is the various processes in which material is joined or solidified under computer control to create a 3D object, with the material being added together (such as liquid molecules or powder grains being fused together).

The essential process elements of 3D printing involve post-processing of a 3D CAD model to break it down into a collection of layers or “slices.” These layers are then produced through the technology inherent to the particular process and deposited on top of each other. The resulting 3D object has all of the physical form, fit, and function intended for the original 3D model; it is a quick process to take intangible numeric data and translate it into an actual physical object.

Since all of these processes “start with nothing” and progressively build the physical model, they are referred to as additive (in contrast to subtractive processes such as traditional machining).

Rapid prototyping machines make use of several different technologies, and each of these different processes will work with a limited range of materials. As such, each method has its best applications. There are numerous technologies on the market; here are the ones that are the most prevalent and widely used:

By using two mirrors (X and Y coordinates) to guide a laser beam through a bath of photopolymer resin, SLA builds successive layers of an object on top of each other.

The typical layer thickness averages 0.004” but can go as low as 0.002” to allow finer precision. (Note: This level of precision is common with almost all 3D printing processes; some printers are capable of even higher resolution than this.) The high level of accuracy enables the production of meticulously detailed models and complex parts designs with a smooth surface finish. Cost is manageable as it is a widely used solution.

While the parts created by SLA are generally perfect for determining form, fit, and function, they may not be the most durable due to the types of materials utilized. They can be sensitive to UV and humidity as well. Stereolithography 3D printing services are available for you at Cad Crowd.

SLS uses a pulsed laser across a layer of powder containing nylon. The laser draws the pattern of the 3D model layer across the surface and fuses the material together; a new layer of powder is then deposited (typically by a roller), and the process repeats.

By using nylon and engineering-grade thermoplastics, the parts generated from SLS tend to be more robust and durable than those made using SLA. Surface finish can be an issue, though, as the process lends itself to producing a somewhat “sandy” or “grainy” finish that could potentially lead to problems with repeated functional testing.

The process used by DMLS is very similar to that of SLS, in that a laser is focused on a powder bed. The heat of the laser beam fuses (sinters) the powder in successive layers until the object is completed. The biggest difference is that DMLS uses metal-based powders instead of nylon or other plastics.

The laser actually melts the powder as each layer is created, so from a structural standpoint, the parts can almost be considered as tough as a metal part created by CNC machining. Another advantage of DMLS printing technology is that it can be used to create internal details that subtractive processes cannot.

As with SLS, the surface finish can be a bit on the rougher side, so post-machining may have to be done depending on the intent of the part. It also isn’t necessarily a fast process, which can lead to higher costs if numerous parts are to be printed.

With FDM, a thermoplastic resin filament is mainly deposited in small “strings” of material from an extrusion nozzle that traverses in X and Y directions. The strings are deposited adjacent to each other, and successive layers are built up to create the completed 3D model.

Pricing is competitive, and a relatively high level of detail can be obtained, but the parts may not be as strong as those generated by other technologies. They also have a relatively poor finish due to the nature of the strings, and it tends to be a slower process.

Borrowing the idea behind a standard inkjet printer, MJF uses an inkjet-style head to deposit fusing catalysts on a layer of nylon powder. Once the base part is complete, a secondary process involving a vacuum is used to remove any un-fused powder residue. The prototype can then be sandblasted and dyed to achieve a realistic color representation of the finished product.

MJF is a fast process that has a good surface finish and high detail levels but is currently limited to using nylon.

It’s noteworthy that these are only a few of the technologies that are commercially available for rapid prototyping purposes. Several others exist, each with its own set of pros and cons. They include:

Click here to learn more about the 3D printing technologies used for prototyping!

As noted previously, from a macro viewpoint, cost and time savings are notably the most significant benefits of migrating to a rapid prototyping strategy. There are many factors that lead to these savings benefits:

It’s easy to look at a finished design on a computer monitor, but most product designers will tell you that sometimes things don’t turn out right when prototype parts are built. The overall product may completely miss the original intent. With rapid prototyping, these types of product deficiencies can be recognized much earlier in the design process.

In addition to design-intent verification, rapid prototyping is an excellent tool for identifying flaws or anomalies in the design itself. Traditional prototyping processes can lead to expensive and time-intensive revisions. With rapid prototyping, changes to the design can be made quickly using the CAD software, and the revised model can be re-sent to the 3D printer for printing.

This is particularly true with parts that will eventually be created using a molding process or generated by a die (such as small sheet metal stampings). The costs and time involved in creating a new tool (or modifying an existing one) can add significantly to the overall design timeframe. The ability to truly realize a part or product without having to develop those types of expensive tooling cannot be overlooked.

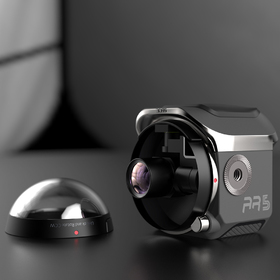

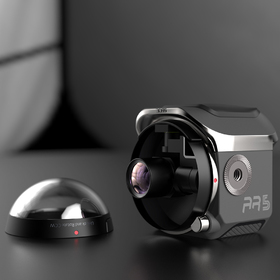

If the right rapid-prototyping processes are used for a given set of parts, it may be possible to print and assemble all the components into a complete and functional prototype.

With products that have no moving parts (such as with many electrical-based items) the opportunity to verify assembly accuracy (e.g., mount hole extrusions for a PC board inside a molded case) is a huge benefit. Models with moving parts can also be assembled to identify any flaws with the intended operation of the product, and changes can easily be implemented.

Objects produced by rapid prototyping technologies can sometimes be used as finished products. This is an excellent option for small and limited production runs, and the various techniques could also allow for a level of mass customization that traditionally could not be offered with any measurable efficiency.

Are you new to rapid prototyping? Do you need help with the process steps? Could you use guidance about the best process for your particular application? Need assistance identifying the process that will maximize time savings and be the best for your overall budget? Cad Crowd can be your ultimate resource by giving you access to top quality and pre-vetted rapid prototyping designers. Contact us today for a free quote.

If you're looking for rapid prototyping services firms or advanced modeling and freelance CAD services, Cad Crowd has you covered. Our freelance professionals are among the most talented in the industry. For any type of project, our flexible 3D design freelancers can help. Whether you're an individual entrepreneur or a full-fledged enterprise, our world-class rapid prototyping service companies can meet the demands of your project. Get a quote now and connect with world-class freelance rapid prototype design services.