Global rank:

4,160

/

121,818

Skill pts: 10

About

I am a Mechanical Engineer with over 19 years of extensive experience in 3D modelling, 2D manufacturing drawing preparation, paper-to-CAD conversion, new product design and development, and reverse engineering.

I possess advanced expertise in SolidWorks, Autodesk Inventor, Siemens NX (UG NX), and AutoCAD, delivering precise, production-ready engineering solutions.

I am known for my strong English communication skills, positive professional attitude, and unwavering focus on customer satisfaction, consistently ensuring high-quality outcomes and long-term client trust

... more »

« less

I possess advanced expertise in SolidWorks, Autodesk Inventor, Siemens NX (UG NX), and AutoCAD, delivering precise, production-ready engineering solutions.

I am known for my strong English communication skills, positive professional attitude, and unwavering focus on customer satisfaction, consistently ensuring high-quality outcomes and long-term client trust

Portfolio

Service offers

Experience

-

Sr, DESIGN ENGINEER

Larsen & toubro limited · Full-time

Apr 2012 –

Present

13 yrs 10 mos

Surat, GJ, India

• Led the 3D Modeling Department, managing a team of 4 engineers and overseeing the development of complete 3D models for all assigned projects.

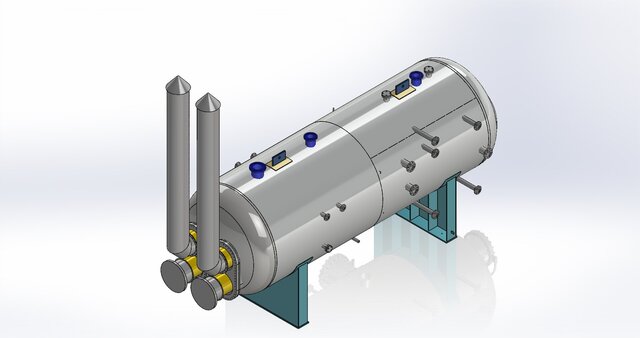

• Prepared fabrication and manufacturing drawings in strict compliance with customer specifications and refinery equipment standards, including Columns, Reactors, Regenerators, Heat Exchangers, and Coke Drums.

• Delivered Critical Requirement Sheets (CRS) within 3 days of LOI, ensuring timely project kick-off.

• Released major nozzle forging requirements within 21 days of LOI, supporting procurement and fabrication schedules.

• Performed thorough checking, approval, and issuance of fabrication drawings to the shop floor, ensuring accuracy and constructability.

• Acted as the key technical interface for obtaining design calculation and drawing approvals from Clients, Authorized Inspectors (AI), and Third-Party Inspectors (TPI).

• Provided technical support to the estimation department for project bidding and inquiry evaluation.

• Maintained close coordination with fabrication shops and cross-functional departments, resolving technical queries and ensuring smooth project execution.

• Developed complete 3D models of process equipment in SolidWorks, successfully completing 25+ critical nozzle cut-out developments with high accuracy.

• Worked extensively in compliance with ASME codes and standards, including ASME Section VIII Divisions 1 & 2, ASME B16.5, B16.47, and B16.20.

• Created and maintained Bills of Materials (BOM) within PLM systems, ensuring data integrity and traceability.

• Handled document control activities, ensuring adherence to quality and audit requirements.

• Implemented 3D modeling and 2D drawing automation using Siemens NX (UG NX) and Autodesk Inventor with iLogic, significantly improving productivity and standardization.

• Currently leading a Design Automation initiative, managing a team of 7 engineers focused on process optimization and digital transformation.

Education

- C. U. Shah College of Engineering & Technology Mechaical engineer, jigs and fixture designing, first class 2003 – 2005 Activities and Societies: New Desing of Jig & Fixture New Desing of Jig & Fixture

Other experience

-

Design Engineer

Designed and developed a wide range of precision fixtures for robotic welding systems, ensuring accuracy, repeatability, and production efficiency.

Enhanced the aesthetic and functional quality of existing product models through thoughtful design refinements.

Actively participated in customer and production issue resolution, driving continuous product improvement initiatives.

Prepared, reviewed, and modified detailed fabrication drawings using AutoCAD and SolidWorks, maintaining strict adherence to engineering standards.

Played a key role in ISO 9001:2000 audit preparation, ensuring compliance with quality management system requirements.

Developed comprehensive Bills of Materials (BOM) and executed accurate system entries to support manufacturing and planning processes.