Product development will only be possible with a product design. New product design services involve different activities, from conceptualization to producing and manufacturing a virtual prototype.

During the product design process, several steps are taken to guarantee that the product is free from defects and ready for market launch. But instead of the traditional form of prototyping that requires something physical for testing and developing the product, virtual prototyping further simplifies the whole process.

Read on to learn what a virtual prototype is and how companies use these prototypes for product development.

What is a virtual prototype?

Virtual prototyping, or VP, is a software-based discipline in engineering. It models a system and simulates and visualizes its behavior under different operating conditions in the real world. An iterative process is followed to refine the design further.

Virtual prototypes revolutionize product development by offering computer-based alternatives to traditional methods used by rapid prototyping companies. Industries such as automotive, defense, and aerospace are embracing this technology to virtually develop and test their designs.

With virtual prototyping, engineering teams can conduct practical simulations, analyze the full-motion behavior of intricate mechanical systems, and explore various design variations to optimize overall performance. This approach significantly reduces costs and development time while ensuring high-quality system designs. By eliminating the need for expensive physical prototypes, virtual prototypes enable thorough testing and evaluation of specific parts, components, and even entire machines.

RELATED: How much does it cost to make a prototype for my new product invention?

Why do you need virtual prototypes?

Engineering simulation is starting to replace conventional testing methods little by little across various industries. These changes make perfect sense if you consider the benefits that virtual prototyping can offer.

- Better virtual collaboration among teams

In this modern dynamic era, many teams are spread across different parts of the world. In cases like this, physical prototypes and their analysis can make collaborations trickier, if not impossible. But with the help of simulation experts and software, all the product teams involved can quickly brainstorm and work together to resolve any concerns.

- Improved marketing

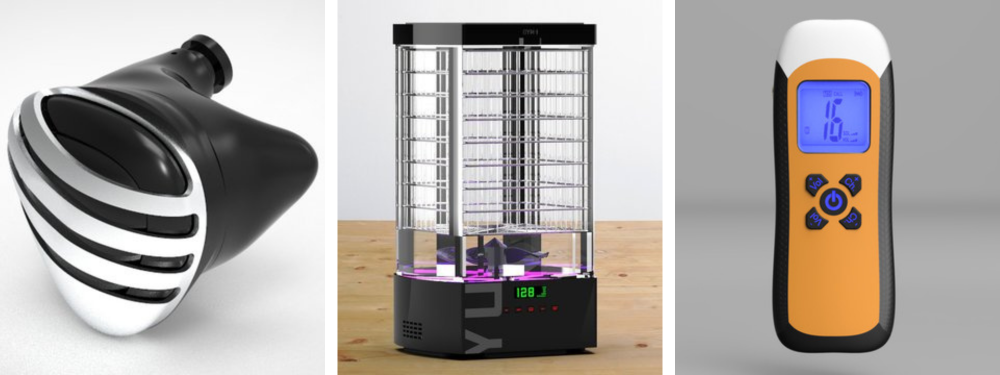

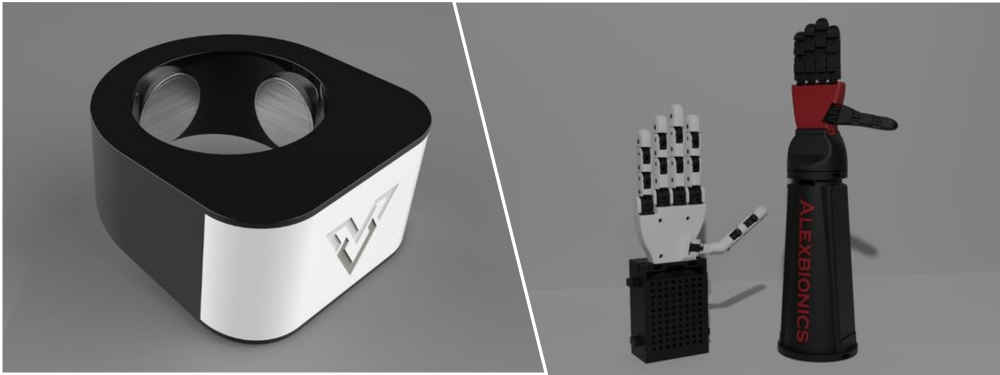

One of the most effective marketing tactics involves creating hype before the project’s launch. This would be challenging to do if your product was still being prepared.

The good news is that designers can use freelance 3D rendering services to develop virtual prototypes that the audience will find appealing and attractive.

These prototypes can be used for social media, billboards, magazines, and other marketing efforts. This will ensure that consumers know about the product before it hits the market.

- Feasible testing under multiple scenarios to eliminate errors

The secret to producing higher-quality hardware products is to use simulation software. This will help you examine the different possibilities and risks of failure. This also allows start-ups to pinpoint flaws in the product design that might not be noticeable during physical testing and prototyping.

In addition, virtual prototyping engineers can test under various conditions that might be tricky to simulate for physical testing. For example, very low or high temperatures, high pressures, or extreme humidity levels can be easily manufactured using simulation software but are challenging to replicate for physical prototyping. Virtual prototypes also reduce human errors because the process is mainly automated.

- Close deals faster

Closing deals will be much faster if investors can visualize the virtual product rather than having to wait around first for the completion of the actual physical product. Aside from this, it also allows showing the product to potential clients quickly.

RELATED: How to design a virtual prototype for your new concept

- Better quality of design

It’s easy to miss a few fundamental errors if you only use a spreadsheet to perform engineering calculations and then build and test a prototype. These errors may lead to flaws in the design that might remain unnoticeable before the manufacturing and distribution of the product, leading to warranty costs and, worse, recalls.

Although hiring CAE analysis designers doesn’t automatically ensure a perfect design, structural or fluid flow simulation tools help engineers test the products first under multiple conditions and significantly enhance their durability and reliability.

- Meet budget goals and timeline

The traditional product development process has plenty of uncertainties regarding the prototype’s performance in the real world. The build-test-iterate cycle of physical prototyping can easily take up to several months before the prototype finally works as how you want it to.

Virtual prototyping, on the other hand, can help cut down most of these uncertainties and time by letting engineers efficiently test and iterate on various design solutions within virtual environments. It adds a sense of predictability to what would have been a chaotic process of product development, making it possible to meet budget goals and timelines.

- Create more competitive products

Excessive reliance on physical experimentation can restrict the creative ideas available for designers to test. However, with virtual prototyping, engineers and exterior design experts can explore imaginative scenarios and designs in a less time-consuming and expensive manner. This approach enables the development of more competitive products that excel in exterior design, performance, and functionality.

- Save resources

The initial product idea can be significantly different from the final one. This is because the product design process still involves plenty of stages before launching the product in the market. It involves developing prototypes through prototype design engineering services and conducting several tests to check their design purpose, function, and others.

After this, changes to the design will be made, and more new prototypes are also developed. It is a lengthy and arduous process with lots of physical prototyping involved, and every physical prototype alone uses plenty of materials and resources.

But with the help of virtual prototyping, you can come up with virtual models and test them with multiple design alterations as necessary. Modern 3D rendering software also allows checking indicators of quality. By switching to virtual rather than physical prototyping, you can save more resources at every stage.

- Faster time to market

The traditional product development process often involves crafting physical prototypes and taking them to the lab for further testing. These tests may reveal a few flaws in the design that require a reconfiguration or redesign.

The cycle of building, testing, redesigning, and retesting can indefinitely stretch your development schedule. But with virtual prototyping, you can eliminate unwanted loops from the design optimization process as it allows virtual design adjustments and testing, cutting both the development costs and time.

RELATED: 10 steps for product design services designing a prototype

Stages of product design and where a virtual prototype fits in

Developing a new product that will thrive in competitive markets involves numerous steps. The following are the stages involved before you can commercialize your product.

- Prototype design and execution

Product design experts list its must-have features depending on a product’s solution. The look and feel of the product, the learning curve for mastering its use, and the overall user experience are other crucial aspects to consider.

Several prototypes are developed based on these. Most of these can be simple physical prototypes to get an idea of the product. But with engineering simulation’s modern advances, virtual prototyping is starting to replace these traditional methods.

Compliance with uncompromising hazard identification and safety standards is critical for any manufacturer, particularly in industries like health technology, automotive, or aviation. Engineers can use simulation platforms to digitally perform all significant tests, often implemented on physical prototypes, to eliminate risk.

- Prototype testing and analysis

After building the prototypes, you must analyze and test them to ensure they are defect-free. Virtual prototyping software can achieve stress, usability, and performance testing in various environments. It’s a quick process, with the software analyzing the different aspects of errors and failures in the product.

- Reiterations and final product designs

The final product is developed using virtual prototyping software according to the results acquired from the steps above. Manufacturing process experts can also design plans designed for outsourcing.

- Release

Small batches of products are made available for initial market release. Manufacturing processes are then optimized depending on feedback.

- Optimizations and improvements

Market reviews and user feedback will reveal if the product needs some improvements that can be performed and tested in the software before a new product version is manufactured.

How Cad Crowd can help

Cad Crowd is a helpful platform where you can find virtual prototyping experts who can help with your product development process. Get in touch with us today to receive a free quote and enjoy exceptional support from our team of skilled professionals.