What is a prototype? If you’re here reading this, you likely don’t need that question answered. However, for clarification, let me explain. A prototype is the first design of a product—the initial phase. However, there are many misconceptions about prototypes.

Many people believe that a prototype is simple and can be thrown together quickly without much forethought—that it essentially pops up immediately from the first concept creation sessions. Others believe that a prototype looks exactly like the final product. Often, both of these ideas are wildly off base.

Typically, a prototype takes a long time to develop, even if you’re using a prototype design service. Famously, Thomas Edison, who had an excellent grasp of the science behind the product, took ages to invent the lightbulb as we know it. Beginning in 1878, it took over a year for him to create the first long-lasting filament for a lightbulb, which lasted a whopping 13 hours.

To create a successful, fully-functioning marketable prototype, you need to be ready for those surprises. Your product will change wildly from what it was in your imagination, perhaps looking like something unrecognizable. Do not hold fast to the mental vision but prepare yourself for the wild ride that comes from designing a new product. Prototyping is like exploring—you are entering a world completely unknown to you, one that has never been seen before.

So, how do you create a prototype? It can seem somewhat complex, and when you’re looking to make a prototype, there are many challenges to overcome. Luckily, you can boil it down to some basic ideas, though in reality, the ideas are repeated several million times for each product that is ever created, so be ready for a long and arduous journey. I’m not trying to discourage you, because invention is incredible, and you can make some truly amazing things. Let’s simplify it: here is a ten-step guide to design the best prototype possible for your business.

How to Design a Product Prototype

1. Initial Concept / Ideating

The first step to creating a prototype is to have an idea. You can’t make something from nothing. Many times, you will have your own idea of what you need already in place. The first step to ideating is understanding what will make you money because as a business, the entire point is to make a profit from what you create.

For this reason, the jumping-off point for many businesses with ideation is the voice of the customer, which we’ll explore in more detail at the very end of the article.

The general idea is that if you want to sell a new product, it makes sense to ask your current customers what they would buy. They’re a built-in marketplace for you since they’re already shopping from your store. You want to reach out to your customers and see what needs they have or challenges they are facing because this can be a springboard for a new idea to design. If you can solve a problem that a customer has, you’re one step ahead of the game, because you know they will buy it and you will be creating a useful product.

Let’s say you don’t have that option. Maybe you’re a new start-up looking for ideas or you want to create a radically new product that you’ve never sold before. How do you come up with an idea for something to manufacture? Here’s the secret – look to a problem that needs solving.

Everyone has heard the stories of people becoming millionaires by creating things like Silly Bandz, Pet Rocks, or the app Flappy Bird, but the lasting products and the vast majority of products are designed to be a solution to a problem – typically one that most people just resign themselves to dealing with forever.

Necessity is the mother of invention. However, laziness is the father. Find something that will make anyone’s life easier, and you will have a product to sell. Take, for instance, the Pivot Power-adjustable power strip created through the Quirky Platform. It is an adjustable, pivoting extension cable so that you can twist and orient your cables in different ways. It did nothing to end world hunger or create space flight, but it did make the lives of everyday people a little bit easier. So much so that the inventor has become a millionaire.

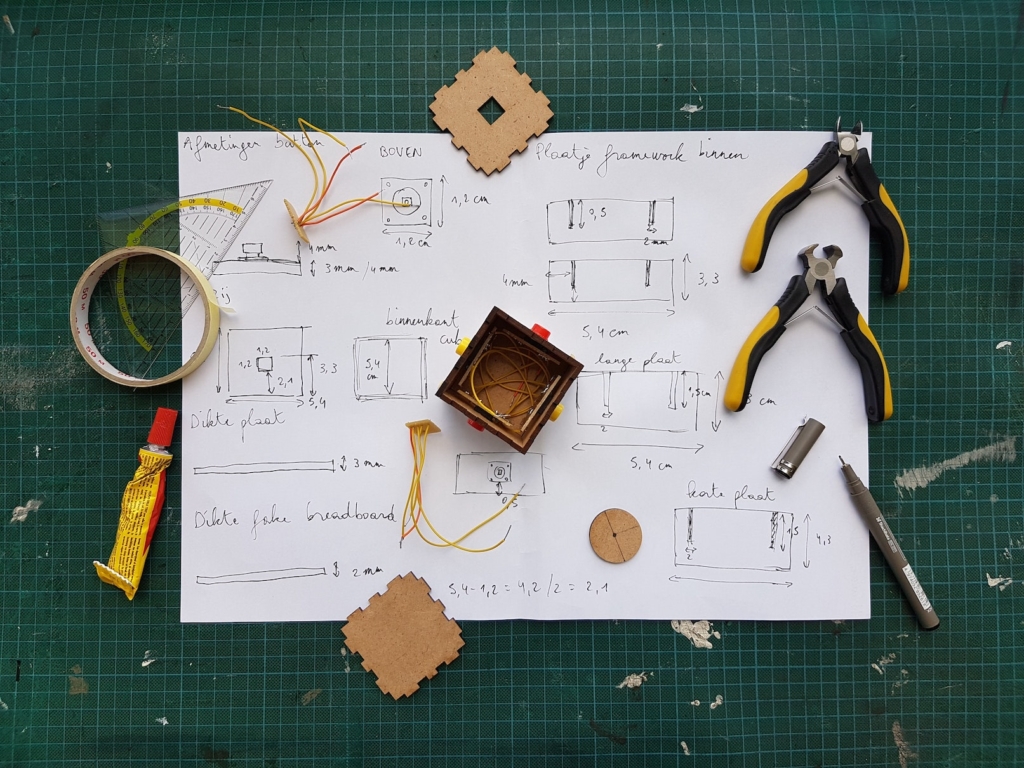

2. Concept Design

The next step in the process is hiring a freelance concept designer and developing the paper prototypes. Whether you do this step yourself or you outsource it, it will look roughly the same. This is the time to sketch, so get out your pen and your paper. Famously, Southwest Airlines was designed and sketched on the back of a napkin in a bar.

When discussing various pricing strategies and how to create a lower-cost airline, the creators sketched out a rough map of the United States with several hub cities that everything would run through, and the rest was history. That company is not alone, as the movie A Bug’s Life, the concept of trickle-down economics, several famous songs, and even the fire hose nozzle were all sketched out on napkins.

Now, I’m not suggesting you go out and purchase a stack of napkins for your next ideation session. The point of this phase, though, is to get something on paper. Obviously, in the digital age, you can get something onto a tablet or in a CAD program. But either way, this is where you start throwing things against the wall and seeing if they stick. The point of concept design is not to create a product, and many times what you put down will look nothing like the final product.

That is fine. This is the sketch that will be written over a thousand times, annotated, torn apart, and built back up. It’s important to have something down so that you can start the tearing apart process.

Companies like Ideo, Deka, and Quirky excel at this process. They use those fancy clear whiteboards like you’ve all seen in the movies to write their ideas and come up with design concepts. You can work with one of them to design your piece, or you can simply get together with your project group and start drawing on sticky notes.

3. Virtual Prototype

Once you have created some Frankenstein conglomerate abomination of what you want your product to look like, you can start to be critical. In the virtual prototyping stage, you will translate this sketch to a computer program, making something that looks presentable and functional.

So, you’ll remove the bolts from the monster’s neck and cover up the scars, hopefully smoothing out the rough edges and inefficient pieces. For example, if you’re designing a new cell phone, you likely won’t want any clunky buttons or additions weighing it down.

The first virtual prototype is going for feasibility because you need to prove that you can actually make something useful with your idea. You can sketch whatever you want on that napkin, but once you’re using prototyping tools and software, the dynamic will drastically change and you’ll start to learn what is feasible and what looks bizarre on your concept. When you can see it in three dimensions, it will help you rework what the product should look like.

Virtual prototyping is the most common step for reaching out to another company or individual for help. The benefits of using a freelance designer for a prototype are fantastic, as many of the articles on this site will illuminate for you. If you have chosen to do your prototyping and design entirely in-house, without reaching out to a company like Ideo or Quirky for help, then you may decide to find a 3D rendering company using AutoCAD or a similar program to help you create a virtual prototype for your product idea.

This step is vital because it is the basis and springboard for everything you will be doing afterward, and especially for the creation of the final product, which makes it even more important that you select a highly qualified and capable individual for your work.

4. Revision

Remember when you were critical of your napkin sketch? Now you get to be critical in three dimensions. Take the concept that your freelance 3D design service created for you and tell them everything you hate about it. Just kidding. What your goal for this portion of the process should be is to take a look at that prototype and streamline it even more.

The virtual prototype and revision pieces of this process are not isolated to singular events. This really should read “repeat steps 3 and 4 until you are sick of looking at your computer.” Every iteration you create will likely have flaws, or at the very least, inefficiencies. You need to adapt your design repeatedly and show it to many people in the process so that you can get a wide array of critique.

This is also the time for the devil’s advocate. You should ask questions about the product’s function that you never thought you’d need to ask, such as what would happen if this cell phone were accidentally dropped into an operational blender, or does this shoe dissolve in common household acids?

The revision process is where you address all the potential issues with a product and try to design for them. I am personally a big fan of the saying that idiot-proofing will just prove that the world can create a better idiot, and it applies to this step of the process. You can’t do everything, but you should think of everything. That way, you can decide what the most valuable aspects of the product are.

Maybe you can’t design the shoe to withstand being dropped in hydrochloric acid, but you can make it hydrophobic so that they never get wet. You think of problems with your design and solve the ones you deem most important in the design process. Revise and revise again until you have something you’re comfortable with.

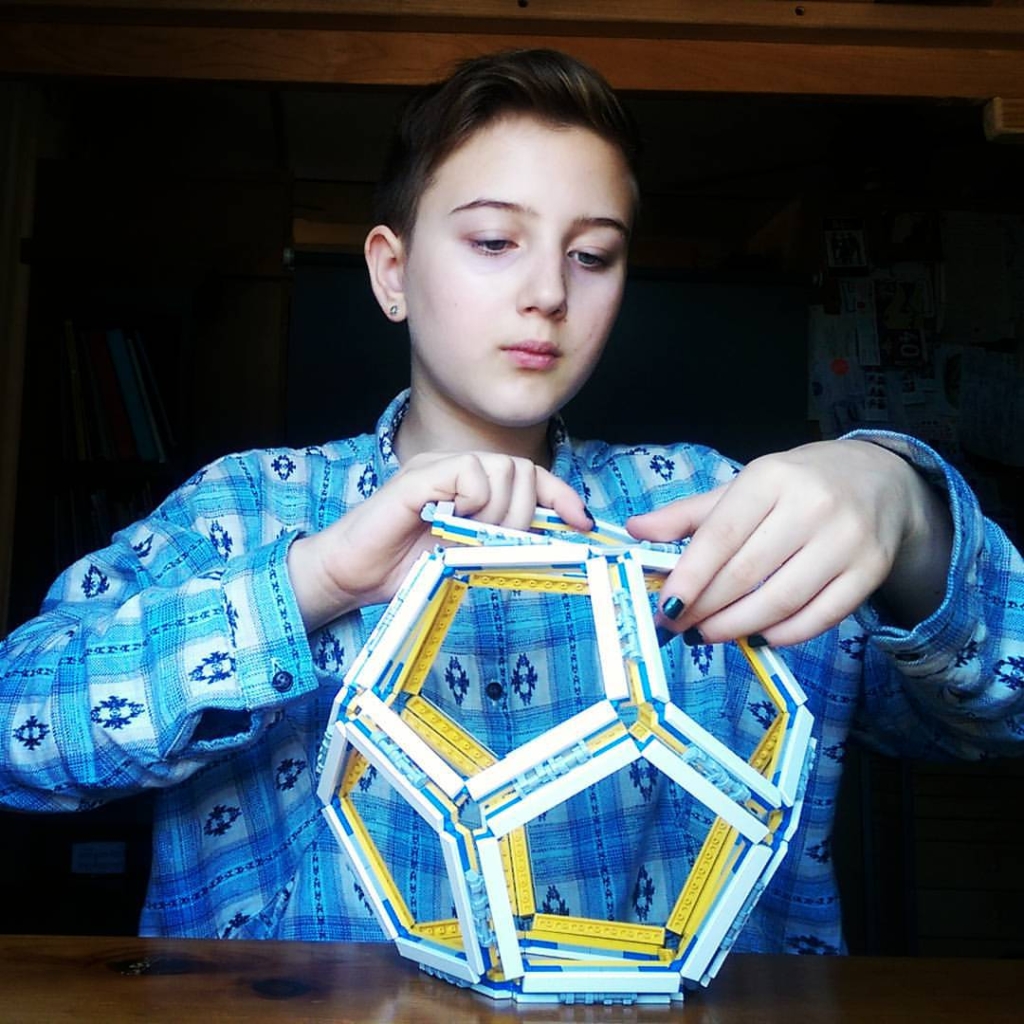

5. Physical Prototype

Now the real fun begins. You have designed and revised, you have ideated, and you have stressed out over every eventuality. Now, though, you get to produce something real and physical. This part can actually be a lot easier than some of the others depending on the nature of your product, especially if you’ve done the previous steps well.

If you have been working with a skilled freelance designer or rapid prototyping specialist, you may have a file that can easily be sent to a 3D printer and turned into a functioning, real-world prototype. If that’s the case, find yourself a 3D printer, go print it out, and move on to the next step.

If you’re still with us on this step, you have several options. Remember, this physical prototype, while not needing to be perfect, will be the basis of what you do from here on out, so make sure it’s a good prototype. You could manufacture the prototype in house. There are several benefits to that.

For one, you don’t need to worry about any exterior contractors or companies that can be difficult to work with or who might copy your intellectual property. For another, it will set you up nicely for the manufacturing process later down the road. However, you may not have the equipment necessary to make your first prototype, and you’re waiting for proof of concept before investing in everything you need.

Your other option is to find an outside contractor. Many freelance CAD designers that you can find on Cad Crowd either work as small-batch manufacturers or have connections with several, so you can quickly find a resource to create a prototype or small batch for your needs. Be sure to verify their credentials and quality before agreeing to work with them, though, because you want to ensure that you get the best quality and best deal for what you purchase. Either way, though, this physical prototype likely won’t last long.

6. Testing

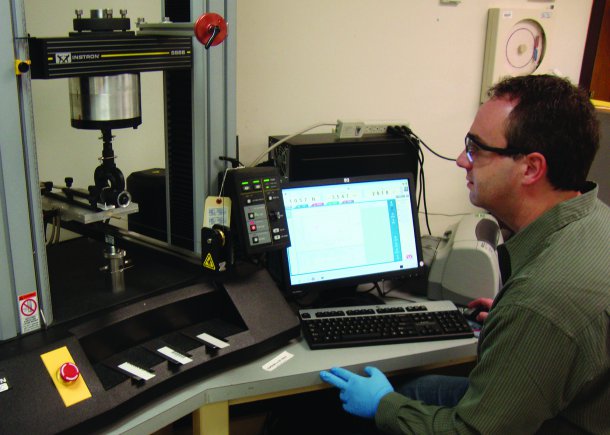

Next, destroy it. Okay, not necessarily. Not all testing is destructive testing. However, that’s typically the most fun. The testing phase is up next, because now you have something physical to test. Think back to the revision phase, where you were playing Devil’s Advocate and coming up with every possible worst-case scenario you could think of, and then designing in the most important ones. That’s where you start with testing.

The testing process should evaluate the critical functions of your product, and probe for weaknesses. So, you will want to examine both those crazy “that could never happen” scenarios, and you’ll want to test the functions you built-in. If it was important that your product can withstand crushing, you’ll need to crush it to see how much it can handle. If it’s important that it can survive being dropped in water, it will need to be dropped in water. Additionally, you should test the extremes of the product – find out where that plastic will melt or where it starts to arc when an electrical current is applied.

Some testing can be done in house, but especially if you’re a young company or entrepreneur, you probably don’t have the equipment necessary to get accurate and useful data from your testing. You can crush a product under your front tire as long as you want, but a certified tensile tester will give you a bit more useful information.

The purpose of testing is not necessarily to prove any of the attributes of the product, but to gather as much quantifiable data as you can, which is why you need high-quality instruments to give you that information.

7. Scaling to Manufacture

Now that you have tested your product, you’re ready to scale it up and begin production. At least, that’s likely where you’re at. There’s always the nagging possibility that the testing process will have revealed a serious flaw or issue with the product and you’ll need to go back to the drawing board, but hopefully, that’s not the case. Let’s assume you’re past all that and you’re now getting ready to scale up production so that this is a manufactured part.

If you produced the prototype in house, as we discussed earlier, you may have a leg up. That gives you the chance to have your equipment already in place and ready to go. But what if, like we just mentioned, you produced the part using a precast dye or mold, and after testing realized that it won’t work in that current state.

Well, then you’ll need to go back to your supplier and get a new fixture designed and fabricated, which extends your lead time typically by several weeks and can cost up to several thousand dollars. That’s just for a fixture or dye, which is relatively simple. You may have already purchased a brand-new machine to make the product or have thought the one you had would do the job, but this has now changed. You could be out tens of thousands of dollars for another machine, or not have anticipated the purchase and your timeline is now delayed.

Regardless, there will likely be some challenges to scaling your product up to the level of manufacturing. You can work with small-batch manufacturers in the meantime if you’d like to go ahead with the remaining actions for creating a prototype, but eventually, you’ll have to address the process of manufacturing. Your life will be easier if you design your prototype initially with easy to manufacture pieces and materials. While 3D printers can do some amazing things, they don’t always translate well to the manufacturing world, so it’s best to consider how it will be produced long term when you are first designing the product.

8. Packaging and Distribution Plans

As integral as any other step in the prototype and manufacturing process is understanding distribution and packaging. If you want, this piece of the puzzle could have been discussed and finished three steps ago, when you built the first prototype. In all honesty, packaging design is its own separate prototyping process.

You need to create a capable package and you need to test it and ensure that it meets all the necessary criteria for when it’s transported and sold. For instance, you don’t want a flimsy and soft package for something that’s incredibly fragile, and conversely, you likely don’t want rigid packaging for a piece of clothing that people want to feel and move.

Packaging is just as important as the product itself. I know it may not seem like it, but the packaging is the first thing the customer will see when buying a product. Think of the first time you took out your brand-new iPhone. The packaging was sleek, innovative even. It protected the phone, cradling it to keep it secure and show off its delicacy.

On the outside, it was emblazoned with the Apple logo, and it was designed to have secret hiding places for all the additional gadgets that they throw in with the phone. The packaging enhances the experience of the product. This should be true of your packaging.

It may not be that you want your product to look like it’s cradled in some new-age sleek packaging. Perhaps you want it to represent the rugged and powerful nature of your products, so you’ll choose a hefty corrugated cardboard, or something even more intense. Either way, you’ll want your logo on the outside and you’ll want to keep the product safe and secure. For this, you need a good packaging design service that acts as protection and marketing.

In addition to packaging, distribution needs to be considered. You won’t be able to clarify your entire supply chain, but you can at least recognize if it needs to be shipped by air freight, if you can consolidate large shipments together, etc. There are many things to discuss with packaging and distribution. This is the point you need to start thinking about it just because you will start sending them out to customers soon.

9. Beta Testing

Beta testing is essentially your first round of shipments. At this point, you’re pretty much done with the prototyping process. Congratulations, you’ve made a product! This is probably the scariest part of the project. The objective for this part of the process is to send your product along to customers and see what they think.

Through user testing, the rubber really hits the road because your product is sitting in front of the people who are actually going to use it and may actually need it for very critical functions in their home or business. That being said, if it doesn’t work right, you will certainly hear about it.

Beta testing is the most important piece in finishing your product. You will probably never get through it without having some feedback requesting changes, because every product is different, and so is every customer. Not to mention, while you may have thought to dump acid all over the product for testing, your customer may have decided to sandblast it in an industrial application, and it failed in a way you never thought of. When you enter into Beta Testing, you should be ready to adjust your product in some way.

Hopefully, it will be a small update, because unlike with software, you can’t necessarily make every change requested within a certain time frame. A manufactured product has very strict criteria for its construction. After the Beta test is complete, you will need to be very creative because you want to fix the problem while changing the product as little as possible. At this point, the majority of the product is set in stone, so you’ll have to weigh cost vs. benefit for whatever change you make.

10. Voice of the Customer

The last step in any efficiency or process improvement session is titled “Control.” The control phase is where you initiate warnings and processes to ensure that the improvements you made in the rest of the process will continue to be carried out. The last step of prototyping is just like that.

After you have completed your project, you’ll want to gather feedback. Ideally, you’ll have a continuous stream of comments for as long as you have this product in place. After Beta testing, everything is essentially continuous testing for the remainder of the product lifecycle.

The voice of the customer is the reason most sellers now have comment sections on their websites. This information is valuable for the quality and profitability of the product, and it can help you improve your product or even generate new ideas for a product to create.

If you keep in contact with your customers, in one form or another, you will gain this valuable information and can keep ahead of the curve. The prototyping process is never truly complete because every product’s iteration is a prototype of the next version.

Cad Crowd’s Product Design Services Can Help Make Your Prototype

It’s important to get the early work done well because that sets the stage for high-fidelity prototyping. Without a good initial concept, there’s not really anything solid to design. Without a fantastic virtual prototype pattern, you’re behind the gun for revisions, physical prototyping, and testing.

Everything involved is intricately interwoven. Cad Crowd’s resources, namely their bevy of talented 3D designers, freelance engineers, and prototype creators are invaluable to creating an excellent prototype.

However you choose to do it, make sure that you are diligent and committed because this is a long term dynamic process. The success of your product depends on the quality of your prototype. If you’d like to find out how we can help, check out how it works!