Global rank:

2,354

/

120,055

Skill pts: 14

About

👋 Hello! I'm Eng. Ahmed Hamdy, a Mechanical Design Engineer with 7+ years of specialized experience in Static Equipment Design including Pressure Vessels, Process Piping, Piping Stress Analysis, and API Storage Tanks.

I bring a deep command of international codes and standards such as:

🔧 ASME Sec. VIII Div. 1 & 2

🔧 ASME B31.1 / B31.3

🔧 API 650

My expertise includes:

✅ Pressure Vessel & Heat Exchanger Design

✅ Process & Power Piping Layouts and Stress Analysis

✅ Storage Tank Detailing and Fabrication Drawing

✅ Compliance with ASME/API design requirements

✅ Comprehensive 3D Modeling and Design Documentation

I deliver engineering documentation with precision and compliance, including:

📌 GA Drawings & Fabrication Drawings

📌 Isometric and Piping GA Drawings

📌 BOM/MTO, Data Sheets & Specifications

📌 Stress Analysis Reports (Caesar II)

📌 Pipe Support & Structural Design Reports

💻 Software Proficiency:

AutoCAD | AutoCAD Plant 3D | AVEVA E3D | SolidWorks | Caesar II | STAAD.Pro | Tekla Structures

I collaborate closely with multi-disciplinary teams and participate in:

🔹 Project Kick-off Meetings

🔹 3D Model & P&ID Reviews, Plot Plan Reviews, HAZOP sessions

🔹 Managing MOCs (Management of Change) from concept to commissioning

As a focal point for Piping Design & Stress Analysis, I ensure all modifications are properly integrated, prioritized, and aligned with project timelines — especially during Turnaround (TAR) Planning.

My goal is to contribute to your project's success by combining technical accuracy with high-quality deliverables and effective communication.

Let’s connect and discuss how I can support your next project with world-class mechanical design solutions.

Eng/ Ahmed Hamdy

Mechanical Design Engineer | Static Equipment | Pressure Vessel | Piping Stress Analysis (ASME/API)

... more »

« less

I bring a deep command of international codes and standards such as:

🔧 ASME Sec. VIII Div. 1 & 2

🔧 ASME B31.1 / B31.3

🔧 API 650

My expertise includes:

✅ Pressure Vessel & Heat Exchanger Design

✅ Process & Power Piping Layouts and Stress Analysis

✅ Storage Tank Detailing and Fabrication Drawing

✅ Compliance with ASME/API design requirements

✅ Comprehensive 3D Modeling and Design Documentation

I deliver engineering documentation with precision and compliance, including:

📌 GA Drawings & Fabrication Drawings

📌 Isometric and Piping GA Drawings

📌 BOM/MTO, Data Sheets & Specifications

📌 Stress Analysis Reports (Caesar II)

📌 Pipe Support & Structural Design Reports

💻 Software Proficiency:

AutoCAD | AutoCAD Plant 3D | AVEVA E3D | SolidWorks | Caesar II | STAAD.Pro | Tekla Structures

I collaborate closely with multi-disciplinary teams and participate in:

🔹 Project Kick-off Meetings

🔹 3D Model & P&ID Reviews, Plot Plan Reviews, HAZOP sessions

🔹 Managing MOCs (Management of Change) from concept to commissioning

As a focal point for Piping Design & Stress Analysis, I ensure all modifications are properly integrated, prioritized, and aligned with project timelines — especially during Turnaround (TAR) Planning.

My goal is to contribute to your project's success by combining technical accuracy with high-quality deliverables and effective communication.

Let’s connect and discuss how I can support your next project with world-class mechanical design solutions.

Eng/ Ahmed Hamdy

Mechanical Design Engineer | Static Equipment | Pressure Vessel | Piping Stress Analysis (ASME/API)

Experience

-

Piping Design Engineer

ASORC · Full-time

Jun 2023 –

Present

2 yrs 7 mos

undefined, Egypt

Activities:-

1/ Executing Management of Change (MOC) for New/Modified Piping Systems.

2/ Doing Field / Site survey.

3/ Preparing Technical Bid Requirements, Specifications and Documents and submit it to Bidders.

4/ Reviewing Vendors / Contractors Technical / Commercial Offers.

5/ Making Technical Bids Evaluation.

6/ Attending 3D Model Review Sessions (30%, 60%, 90%)

7/ Attending HAZOP, HAZID, SIL Sessions.

8/ Meetings with the Vendors / Contractor.

9/ Follow Up Execution of Projects, and compliance with ASME / API Standards.

Prepare:-

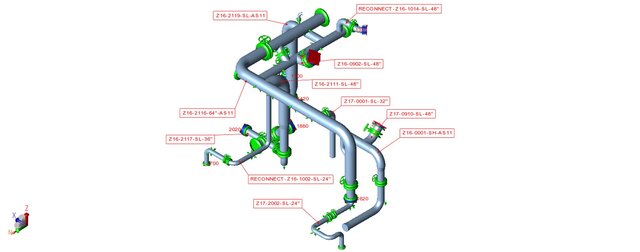

1/ 3D Model.

2/ Shop & Fabrication Drawings.

3/ Isometrics Drawings, As-Built Drawings.

4/ Piping General Arrangement (GAs).

5/ Mechanical Calculations Notes.

6/ Bill of Materials. (BOM)

7/ Equipment & Line Lists. - Technical office engineer Power House Egypt · Full-time Mar 2018 – Present 7 yrs 10 mos undefined, Egypt

Education

- Assuit University Bach. of Mechanical Engineering, Mechnical Engineering, 3.0 GPA 2012 – 2017