It wouldn’t be an exaggeration to say that aerospace is one of the world’s most demanding and critical industries. Many things are at stake here, so it only makes sense that the field requires intensive processes, from the planning stage to product development, product testing, and the final manufacturing stage. Fortunately, 3D scanning services and technology are here to improve further and simplify these processes. These technologies offer a more comprehensive and accurate view of the aircraft and its still-developing components.

Manufacturers can then use these data to identify flaws and correct them immediately before they create severe issues in the real world. 3D scanning application in reverse engineering also helps recreate or create new legacy parts. 3D scanning is also extensively used to produce complex casting parts and molds. It helps in the development of entire aircraft fuselages as well as other more extensive parts and components. This can also come in handy for creating customized accessories and parts for individual aircraft.

RELATED: Top 10 applications of 3D scanning services used by companies and engineers

3D scanning services defined

3D scanning involves the preparation of three-dimensional digital models with the help of imaging devices like digital laser scanners. The process typically uses two or more points of view to produce 3D modeling data. Subsequently, the 3D modeling design firm can utilize the data to create 3D models or visual depictions of objects. 3D scanning services are now used in various industries, changing and improving people’s lives. Since scanning objects is made faster and easier, manufacturers have started to use the process and technology more often.

This state-of-the-art technology helps save money and time, ensures better accuracy, and reduces the risks of human errors. Engineers and freelance 3D scanning service experts can use 3D scanning for inspection and quality control to create products that meet specifications before the start of mass production. 3D scanning services and technology have found their way into various production environments in different fields, including manufacturing, construction, medical, spacecraft part design, and aerospace industries.

RELATED: How reverse engineering services use 3D laser scanning for design

This application is also anticipated to grow bigger and better, with 3D scanning continuously influencing and revolutionizing new industries and, at the same time, cutting costs for all sizes and types of manufacturers across the globe. The ever-increasing adoption and application of 3D scanning professionals and technology depend on the specific industry in which they are applied. But with the improved accessibility of this technology, it has started expanding into new fields and sectors with a positive impact on the world’s overall economy.

One of the most common misconceptions about 3D scanners is that they only help copy object designs. Most people don’t know that engineers can use technology in many ways. The increasing number of 3D scanning software programs has allowed engineers, architects, and other professionals to turn vast amounts of information into visual models. Some companies even started to offer more budget-friendly 3D scanning services with growing popularity.

RELATED: 3D modeling: an overview of history & industry applications

3D scanning services for manufacturing

3D scanning is a critical aspect of the design and manufacturing processes. Technology has continuously innovated and changed the manufacturing industry over the years. Since 3D scanning was first developed during the 1960s, 3D scanning has developed and improved to change traditional manufacturing methods. This function integrates convenience to use and application to supply chains in various industries, from movie production, aerospace design services, to automotive and more.

3D scanning uses non-contact laser light to capture a 3D object and its precision points. It allows for capturing fine details digitally, measuring complex geometries, and creating free-form shapes. This data capture is usually referenced as point clouds with the precise points of an object displayed together in digital files.

RELATED: Manufacturing services and tool design engineering

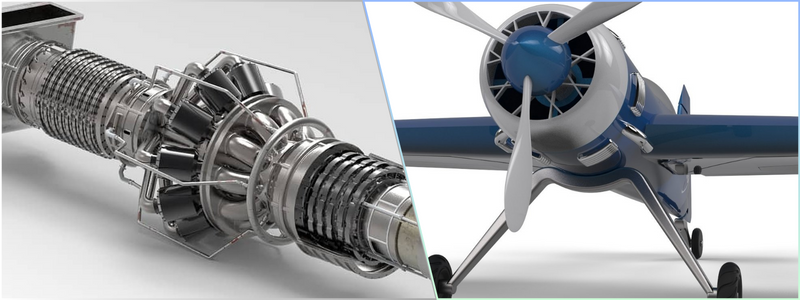

Different 3D scanning solutions for the aerospace industry

Since the aerospace industry requires high-precision components and parts, 3D scanning services and technology play a significant role in design, assembly, manufacturing, and MRO or maintenance, repair, and overhaul. The non-contact measurement technology captures millions of data points to inspect and model complex parts, including spacecraft part design & freelance design engineering services. The remarkably high speed that 3D scanning uses to capture the data can further reduce airplane downtime.

3D measurement of the engine inlet lip

Bird strikes and lightning strikes are unsurprisingly common in the aerospace industry. These incidents can lead to the fuselage deformation and other specific parts, such as the engine inlet lip. Timely maintenance and inspection are necessary to prevent potential accidents and ensure the airplane’s safe operation.

RELATED: Freelance aerospace engineering services, cost, rates, and pricing for companies

Technicians traditionally used pit gauges and visual inspections for detection. However, both methods depend a lot on the operator, not to mention that it may take hours to pinpoint wrinkles, dents, and bulges. With the help of 3D scanning, aerospace companies can accumulate more precise engine inlet lip data in 3D to quickly and efficiently identify deformed areas. These data can help operators prepare to act fast and implement the most effective maintenance.

Inspection of the aircraft wing

During a flight, the wings of an aircraft deform because of the aerodynamic load. When a plane is in flight, this wing deformation significantly affects the aircraft’s overall aerodynamic performance, which cannot be qualified and checked more intuitively. Airplanes are traditionally subject to inspections according to the number of hours in flight or set timelines. 3D scanning technology helps with the inspection of the deformation of airplane wings.

The service provider can acquire the wing’s spatial positions and capture more in-depth 3D data using 3D scanners. After the complete measurement, the results will be compared to the original CAD model to pinpoint deformed areas. Actual parameters such as the defect’s depth, length, and width can undergo more intuitive observations. It results in a complete digital copy to ensure that everything is noticed.

RELATED: How 3D modeling technology enhances aviation design services for aerospace companies

Assessment of flight damage and MRO

Air travel has always been considered the safest mode of long-distance travel because of the fewer accidents recorded. The International Civil Aviation Organization also sets strict international standards for efficiency, security, and safety for air travel. MRO (maintenance, repair, and overhaul) is critical in the aerospace industry.

In the case of in-service flights, a reduction in the time it is grounded for inspection and evaluation also lessens the potential loss in revenue it may cause for airlines, provided that the precision of the inspection is not jeopardized. Even an hour of downtime for an airplane can lead to colossal financial losses for an airline company because of the enormous investment involved. 3D scanning services and technology can offer an easy way out of this problem with its outstanding performance in terms of portability, efficiency, and precision.

RELATED: How the aerospace industry is using CAD design services: drafting, modeling, and prototyping

Product development

Manufacturing companies in the aerospace industry is now shifting its focus to market-driven products with better cost-efficiency than traditional technology-driven products with improved performances. To adapt to these evolving needs, a growing number of aerospace engineering experts are crafting new models derived from the original ones, rather than starting the design process from scratch. Analysis methods, such as computational fluid dynamics, play a critical role in the design process.

3D scanning services and technology allow the scanning of the structure of every designed aircraft element to produce 3D data. The data gets imported to professional software to develop CAD models that will then serve as the basis of data used by mechanical engineering firms for CFD analysis. CFD plays a role during the initial analysis, where different configurations are tested, which helps reduce the design costs. The data can also help measure and inspect minor structural deformations during flight operation tests to optimize airplane design.

CFD engineering services are available to companies needing assistance with configuration analysis. Precision is always the top priority in aerospace design because even the smallest flaw can compromise product development, leading to complete performance failure. 3D technology is an efficient way of capturing precise 3D data that helps improve the reverse engineering of the design of airplane structures.

RELATED: Top 101 engineering and mechanical design firms in the United States

This serves as a helpful guide that allows engineers to understand better the intention and purpose of the design and the technical features to develop more efficient airplanes at a fraction of the cost. Due to the large surface area of airplanes, inspecting them using traditional methods can be challenging because of their limited measurement areas.

More applications

3D scanning services and technology are also applicable to inspecting manufactured aircraft parts. It helps develop 3D models of various parts and elements for virtual assembly, including 3D modeling services for machine parts. The visual representations of the physical models can reduce the need for physical assembly prototypes. It helps with more efficient verification of the design’s accuracy, identification of potential errors in the assembly, and modification of the design model.

RELATED: How to evaluate the quality of a 3D model for parts & products

How Cad Crowd prepares the future of aerospace with 3D scanning

Like other fields, the aerospace industry deals with different uncertainties now and in the future. It should be proactive and react fast to keep up with the changes to thrive and grow. 3D scanning services and technology are set to play a significant role in how the aerospace industry will embrace the uncertain future. Cad Crowd is the leading platform where you can find the best 3D scanning service experts to help your aerospace company adapt and grow.