Developed for the first time in the 1960s by the creator of Sketchpad, Ivan Sutherland, 3D modeling can be simply defined as the process of creating a three-dimensional digital visual representation of an actual object using specialized computer software. Think of it as realistic drawing, but with much more complexity involved, because you can incorporate real-time data into the model and interact with the object using a computer. Just like a physical model, the object can be rotated, flipped, exploded, or manipulated in all sorts of ways on the screen.

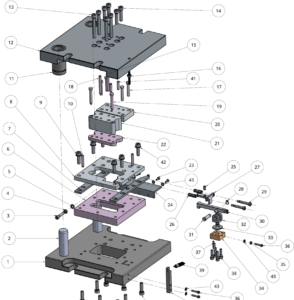

Some software makers market their 3D programs and 2D programs as separate packages, but there are plenty that combine them into one. Depending on the software used and hardware specifications of the computer, 3D models can be created through several different procedures such as algorithm-based modeling, hand drawing (on the computer), or scanning. Texture mapping will help create more refined details on the surfaces of the models. To make every model as realistic and interactive as possible, it must be based on a collection of data points. 3D models can be divided into three major types as follows, based on the data points they use:

Wire-frame 3D Models

Wire-frame 3D Models

3D models of this type may not look realistic at all because their constructions or drawings consist only of networks of wires (hence wire-frame), connected to make certain shapes built from a combination of nothing but lines and arcs. All surfaces are transparent, rendering everything in the background visible on the computer screen.

Surface Models

Surface Models

The more realistic 3D models have more definitive surface textures. Rather than using only lines and arcs, surface models look more like paper models, as each sheet of “paper” can be placed anywhere on the screen at different angles to build the desired shapes. It’s also possible to separate and join the surfaces to make further modifications. Since the surfaces are opaque or translucent – as opposed to transparent – background areas are obscured, creating a more realistic visual representation.

Solid 3D Models

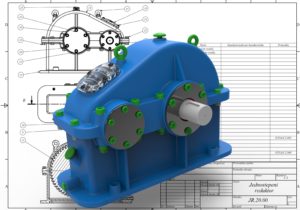

The most computationally demanding type of 3D modeling is solid 3D models. Although they look similar to the previously mentioned type of 3D model at a glance, this model type incorporates more data points than any of the others. These include weight, material density, the center of gravity, and mechanical stress. Not only is a solid model the most realistic, it’s also the most widely used in engineering to make prototypes.

The most computationally demanding type of 3D modeling is solid 3D models. Although they look similar to the previously mentioned type of 3D model at a glance, this model type incorporates more data points than any of the others. These include weight, material density, the center of gravity, and mechanical stress. Not only is a solid model the most realistic, it’s also the most widely used in engineering to make prototypes.

An easy example of the three types is the 3D model of a simple cube. To draw a wire-frame model, all you need to do is make twelve lines and connect them by specifying the coordinates of each point; the surfaces are empty spaces, allowing you to see the background through the cube. Only the lines are visible on the screen. To transform the cube into a surface model, you must cover all the sides with opaque or translucent surfaces. Although you can only see three planes on the front, it is important to create all six planes to make it as realistic as possible when you interact with the cube, like rotating it. For a solid model, you can add more data points such as materials and tensile strength of the frame, making an even more realistic model.

Why Use 3D Modeling?

It seems that people have a strong tendency to associate 3D modeling only with architectural design. This is not entirely wrong, but 3D modeling can be used in just about any industry including consumer products and even educational purposes such as in schools. Gaining a visual representation of an object is just one benefit. In addition to getting an accurate rendering of the object, 3D modeling (at least from an engineering perspective) gives a great deal of technical detail with nearly zero errors, if any at all.

When used within the scope of engineering or architecture, such as prototypes of bicycles or building designs, solid 3D modeling offers a precise resemblance of what the final object will look like and function like in a real-life scenario. The same thing applies in other fields of study, such as biology or chemistry, where 3D models are used as visual representations of body organs or the chemical structure of an atom. This means that computer-aided design and drafting (CADD) can help professionals create 3D models for both theoretical (in the case of prototypes) and existing objects (such as a 3D model of the human heart), in much greater detail.

More accurate 3D modeling opens the door to better planning as well. Architects may take advantage of 3D modeling to gain easy access to a theoretical building and try to improve its aesthetic or overall structural integrity. They can try to alter parts of the design, foundation, room layout, and everything else even before the building actually exists. It’s better than changing a design plan in the middle of ongoing construction work. Engineers and product designers have the same advantages. They can figure out solutions to design challenges well ahead of production.

Some of the biggest benefits of using 3D modeling for professionals are:

Accurate planning: Regardless of the project, professionals can detail an action plan with surgical-level precision for each step. Whether the models are theoretical or depictions of existing objects (by scanning method), professionals can work with a precise model and incorporate all the necessary data points, based on which they can scrutinize every part of the object in a more convenient way. They can figure out potential weaknesses in the structural integrity of a product/site and implement changes to the model itself rather than to the actual object, avoiding mistakes with costly consequences later in the process.

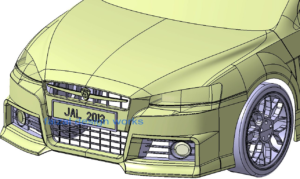

Accurate planning: Regardless of the project, professionals can detail an action plan with surgical-level precision for each step. Whether the models are theoretical or depictions of existing objects (by scanning method), professionals can work with a precise model and incorporate all the necessary data points, based on which they can scrutinize every part of the object in a more convenient way. They can figure out potential weaknesses in the structural integrity of a product/site and implement changes to the model itself rather than to the actual object, avoiding mistakes with costly consequences later in the process. Real-world visualization: One of the greatest advantages of 3D modeling is that the data points can be anything to do with the object itself or external factors, such as weather and possible interactions with other objects including humans/users. When building a car, for example, 3D modeling can provide an accurate depiction of how well the vehicle will run while exposed to heavy rain, various wind speeds, slippery road condition, or a situation where the driver pushes the engine to the limit. Although test results based on computation alone cannot completely replace the need for test drives, the data can at least provide a reliable reference point. Based on those data, engineers and designers have a good idea of whether to make changes or validate the design plan for production.

Real-world visualization: One of the greatest advantages of 3D modeling is that the data points can be anything to do with the object itself or external factors, such as weather and possible interactions with other objects including humans/users. When building a car, for example, 3D modeling can provide an accurate depiction of how well the vehicle will run while exposed to heavy rain, various wind speeds, slippery road condition, or a situation where the driver pushes the engine to the limit. Although test results based on computation alone cannot completely replace the need for test drives, the data can at least provide a reliable reference point. Based on those data, engineers and designers have a good idea of whether to make changes or validate the design plan for production. Speed: As mentioned earlier, a 3D model can be drawn from the ground up or from scanning an actual object. This eliminates the boundaries of what professionals can do with the model. In other words, the applications are limitless. Many examples of 3D modeling revolve around the creation of a product, such as building a skyscraper or designing a car. Still, there is no rule to suggest that it cannot be used for the opposite function too, like the demolition of a building. If the building is quite tall, the demolition process requires proper planning to eliminate the possibility that its destruction will cause damage to other sites. With 3D modeling, demolition engineers can more quickly determine the most efficient way to demolish a building without creating unnecessary damage to the surrounding area. When speed is a critical factor (such as in rescue attempts in burning buildings), 3D modeling offers a reliable method to develop plans of action more quickly.

Speed: As mentioned earlier, a 3D model can be drawn from the ground up or from scanning an actual object. This eliminates the boundaries of what professionals can do with the model. In other words, the applications are limitless. Many examples of 3D modeling revolve around the creation of a product, such as building a skyscraper or designing a car. Still, there is no rule to suggest that it cannot be used for the opposite function too, like the demolition of a building. If the building is quite tall, the demolition process requires proper planning to eliminate the possibility that its destruction will cause damage to other sites. With 3D modeling, demolition engineers can more quickly determine the most efficient way to demolish a building without creating unnecessary damage to the surrounding area. When speed is a critical factor (such as in rescue attempts in burning buildings), 3D modeling offers a reliable method to develop plans of action more quickly.

It is worth mentioning that 3D modeling is not only for professionals, although the cost of acquiring the hardware and software necessary is still relatively expensive. Students and hobbyists can play with 3D modeling to get familiar with designs or even create simple objects such as furniture, toys, household items, and other creative designs.

3D Modeling Design for 3D Printers

3D Modeling Design for 3D Printers

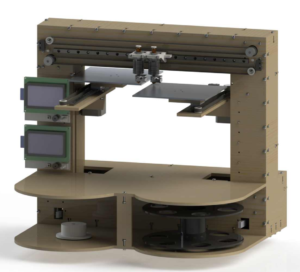

Whether or not you realize it, 3D printing has been around for decades, although it was not until recently that the price for the machine has plummeted to the point where many (if not most) people can purchase consumer-grade 3D printers for everyday use. 3D modeling and 3D printing are an exciting combination to imagine, and they’re likely becoming easier and cheaper to get.

It is easy to assume that all 3D modeling can be brought to life using a 3D printer, but that is not always the case. Although there is no limitation on size, shape, and level of detail you can make with 3D modeling, some 3D printers are not designed to create high-quality objects. The printers have maximum layer resolutions, print sizes, and colors. Certain brands also work with proprietary filaments. As technology develops, however, it isn’t far-fetched that 3D printers will be in millions of households sooner rather than later.

The combination of 3D modeling and 3D printing allows anyone and everyone to be engineers, architects, designers, and, to some extent, inventors. People can pour their ideas into more realistic models without spending too much money creating life-size prototypes. Even students can participate in the excitement by drawing creative ideas in 3D modeling and printing those ideas into physical objects anybody can interact with. Of course, it takes time to understand everything there is to know about the process, but the skill set required to build 3D models is far from impossible to learn and master.

Cad Crowd Has Freelance 3D Modeling Services

If you have a project idea that requires 3D models, Cad Crowd can help. Our pre-vetted and experienced freelancers worldwide provide 3D modeling design services and photorealistic 3D rendering services that can make your project idea a reality. Find out how it works.

You can also launch a contest and choose from numerous design concepts. Learn how to launch a design contest in less than 15 minutes.

This is a very interesting overciew. I like how you take time to explain a bit about the history and not just about today’s 3D modeling

Hey Cam Machine,

Good point, will get an update to this article posted over the next week or will get a fresh one posted to over it 🙂