Global rank:

2,557

/

119,599

Skill pts: 12

2D & 3D Modeling Solidworks 2025

Assembly Design

Design for Manufacturing (DFM

Motion Analysis

Weldment Design

About

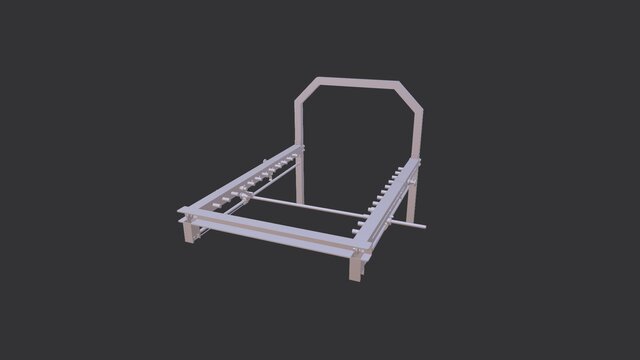

I'm a Mechanical Design Engineer specializing in the design and development of gym and strength training machines. With a strong background in 3D CAD modeling, simulation, and manufacturing, I deliver robust, functional, and production-ready designs tailored for the fitness industry.

Using SOLIDWORKS as my primary tool, I create accurate part models, detailed assemblies, and manufacturing drawings optimized for sheet metal, weldments, and machined components. I hold a CSWPA certification in Sheet Metal and am actively expanding into surface modeling, weldments, and advanced motion and stress analysis.

Key Skills:

Gym & Fitness Equipment Design

3D CAD Modeling (SOLIDWORKS)

Sheet Metal & Weldment Design

Motion Analysis & Structural Simulation (FEA)

Assembly Design & Optimization

Technical Drawing & GD&T

DFM (Design for Manufacturing)

I focus on designs that don't just look good in CAD — but actually perform under load, are easy to fabricate, and meet real-world usage standards. If you're building gym equipment that demands strength, precision, and user safety, let's work together to make it happen.

... more »

« less

Using SOLIDWORKS as my primary tool, I create accurate part models, detailed assemblies, and manufacturing drawings optimized for sheet metal, weldments, and machined components. I hold a CSWPA certification in Sheet Metal and am actively expanding into surface modeling, weldments, and advanced motion and stress analysis.

Key Skills:

Gym & Fitness Equipment Design

3D CAD Modeling (SOLIDWORKS)

Sheet Metal & Weldment Design

Motion Analysis & Structural Simulation (FEA)

Assembly Design & Optimization

Technical Drawing & GD&T

DFM (Design for Manufacturing)

I focus on designs that don't just look good in CAD — but actually perform under load, are easy to fabricate, and meet real-world usage standards. If you're building gym equipment that demands strength, precision, and user safety, let's work together to make it happen.

Portfolio

Experience

-

MECHANIC DESIGN ENGINEER

Fiverr · Part-time

Nov 2024 –

Present

1 yrs 2 mos

Egypt

Over the past 2 years, I've worked as a freelance Mechanical Design Engineer on ▒▒▒▒▒▒, delivering high-quality CAD and engineering solutions to clients worldwide. My focus has been on designing gym machines, industrial parts, and mechanical assemblies using SOLIDWORKS.

I've completed projects ranging from concept development and 3D modeling to detailed engineering drawings, simulation (FEA & motion), and DFM-ready models for manufacturing. I pride myself on clear communication, fast turnaround times, and engineering accuracy that ensures my designs work in the real world — not just on screen.

▒▒▒▒▒▒ Experience Highlights:

Designed over 15 custom gym/fitness equipment systems

Delivered 3D CAD models and technical drawings for clients in the US, UK, EU, and Asia

Provided motion and stress analysis to validate mechanical performance

Helped startups and manufacturers turn product ideas into production-ready designs

My ▒▒▒▒▒▒ experience sharpened my ability to understand diverse client needs, work under tight deadlines, and deliver engineered solutions that are both innovative and manufacturable.

Education

-

Tanta University

Bach of engineering, Mechacnical Engineering, 3.4 GPA

2023 – 2027

(expected)

Activities and Societies:

Volunteer – MEC PR Specialist.

Team Member – Formula Student (Engine Management)

Gained a solid foundation in mechanical systems, design principles, materials, and manufacturing processes. Specialized in mechanical design and product development, with a strong focus on 3D modeling, simulation, and CAD software — particularly SOLIDWORKS. Completed coursework in machine design, mechanics of materials, thermodynamics, and finite element analysis.

Key Projects:

Capstone Project: Designed and developed a [e.g., “selectorized gym leg press machine”], incorporating 3D modeling, motion analysis, and DFM techniques.

Created assemblies and detailed manufacturing drawings for various mechanical systems.

Tools & Skills Developed:

SOLIDWORKS (Part, Assembly, Drawing, Sheet Metal)

Engineering Drawing & GD&T

Structural & Motion Simulation (FEA)

DFM (Design for Manufacturing)

Problem-solving, teamwork, and technical communication

Licenses & Certifications

- CSWP-Sheet Matal Jan 2025 – Present See credential

- CSWP Jan 2025 – Present See credential