This guide shares everything you need about new electronics prototyping for hardware startups and design agencies. Electronics prototyping is the process of testing an electronic product’s design, appearance, functionality, safety, and manufacturability, and the electronics prototyping market is expected to see significant growth until 2031. This post is your guide to the main steps in developing new electronic and hardware products and how this testing is involved.

Table of contents

- What drives the demand for electronic prototyping?

- What are the main trends in electronics prototyping?

- Why do you need electronic prototypes?

- What are the different types of electronic prototypes?

- What tools do you need for electronics prototyping?

- Steps for developing new electronic and hardware products

- What’s Next?

- The Bottom Line

- How Cad Crowd can assist

Electronic system design has an important role to play in the development of an electronic prototype. There are two main types of electronics prototyping: PCB prototyping and electronic product prototyping services. While electronic product prototyping focuses more on the design and functionality of the end product, PCB prototyping focuses more on the product’s electronics aspects. Since it is proven that prototypes are a critical step in any electronic product’s development, the current electronics prototyping market is projected to see remarkable growth in the next few years or so.

RELATED: Find the best prototype engineering firm services

What drives the demand for electronic prototyping?

PCB designers use PCB prototyping to test the functionality of solutions with each new change made. This also allows teams and designers to test at the different design stages. Depending on the requirements, they can make the necessary adjustments to tailor their solutions before the start of production. The benefits of electronics prototyping will help the market grow shortly.

Before the final product is created, PCB design specialists go through a series of iterations to develop a PCB design, which can be very long and tedious. Electronics prototyping speeds up the design and manufacturing process through visual assistance, comprehensive testing, and reduced rework. Minimizing the timeline for prototype fabrication further drives the growth of electronics prototyping.

RELATED: Tips for PCB design services creating new products

What are the main trends in electronics prototyping?

Different industries, such as consumer electronics, use electronic prototyping for PCB design, functional testing, final product design, and conditional testing. The solution offers reliable and accurate prototypes, making it easier to address design concerns throughout the process of development. Electronics prototypes also help consumer electronics manufacturers identify the necessary product adjustments or packaging options for final PCB designs.

This trend also contributes to the continued growth of the electronics prototyping market. The automotive industry also adopts electronics prototyping as an ideal solution to help lower manufacturing costs. Electronic prototyping and design solutions help the industry improve product quality and reduce manufacturing process costs. All of these trends constantly contribute to the growth of electronics prototyping.

RELATED: Cost to design a new electronic product, develop PCB hardware & prototype rates at firms

Why do you need electronic prototypes?

Hardware startups and design companies trying to launch a new electronics product in the market need to be familiar with the entire hardware prototype development process. This includes the different prototypes you should make, the electronics prototyping tools available, and the steps involved in developing new electronic and hardware products. Electronic prototypes are crucial not only to the performance but also to the overall lifespan of new products. Product engineering experts specialize in developing prototypes for you to test every idea, determine its viability, and make necessary adjustments before going full steam into production.

3 Top reasons why electronics prototyping is a necessity

1. Remove flaws before products reach the customers

By addressing performance concerns early, you can gain your customer’s confidence and trust, improving your company’s reputation.

RELATED: What are electronic manufacturing services (EMS) for new products & prototype design?

2. Save on the cost and time of rework to stay ahead of your competition

In today’s cut-throat economy, cost efficiency and timing set successful companies apart from those struggling to stay afloat. PCB assembly and design experts can develop high-quality electronic prototypes that give you this edge. Experienced engineers provide helpful tips on improving your products’ performance and ways to overcome manufacturing challenges. The best engineers are flexible enough to make room for any last-minute changes.

3. Know and understand all your requirements

Electronics prototyping is crucial if you need to develop a system, particularly a large and complicated one. While PCB design layouts can help, these are not substitutes for prototypes. Live models will let you see and check any issues with thermal management, packaging, etc. They also give you a better understanding of resolving problems before going into production.

The prototype development process also gives you an idea of your actual requirements to help you achieve full functionality. Generally, an electronics product that has undergone prototyping has a better design quality, lifespan, and performance, all features users require and expect. A prototype design engineering professional also helps you achieve one of your primary goals: lower production costs.

RELATED: Hiring the best electrical engineers & freelance PCB designers

What are the different types of electronic prototypes?

This guide discusses prototyping a typical consumer electronic product with electronics inside and an outer plastic enclosure. Such items can be for home automation, IoT devices, pet products, or other “smart” devices. Every prototype has a specific purpose. Whether to present the product’s functionality, use it for marketing, test ergonomics, secure funding, gather additional data about the product, or test a few assumptions. For this reason, every stage of product development requires a different type of prototype most suitable for that particular stage in question.

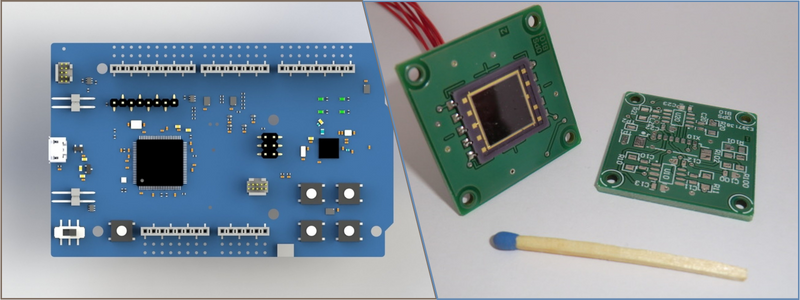

1. Proof-of-concept prototype

The POC or proof-of-concept prototype is usually the initial tangible representation of a concept or idea whose goal is to prove its technical feasibility in the real world. In the case of electronic design services, this is often made using an off-the-shelf development board such as Raspberry Pi or Arduino. Arduino is an easy-to-use open-source platform for electronics prototyping and is helpful in the development of several hardcore electronic projects. With plenty of sensors, compatible hardware, and add-on boards known as shields, you can use Arduino to create whatever you have in mind.

RELATED: Different kinds of prototypes and how to use them for your design project

Various boards are also available that make hardware prototyping more unique and accessible. POC prototype only has one purpose: to show the core functionality of a product idea. At this stage, considerations of design, aesthetics, and custom PCBs are not yet a priority. The electronics may also be enclosed inside an off-the-shelf plastic box or in a wooden box drilled with holes for buttons. There are also enclosures for handheld devices, waterproof enclosures, and metal enclosures available online if this is what your project needs.

Some manufacturers even provide services for cutting out slots and holes in the enclosure, depending on your requirements. For something more custom-made, processes such as laser cutting and 3D printing can also be used to create a custom enclosure. However, keeping everything in its simplest form during the POC stage is still recommended.

RELATED: What are industrial design rates & costs at product design services firms?

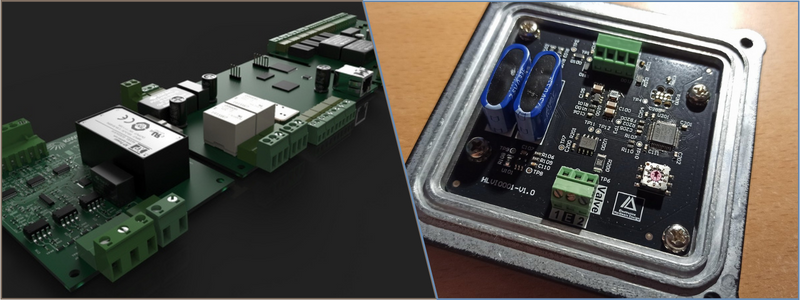

2. Functional or “works-like” prototype

Even though prototyping boards offer better flexibility with different shields and sensors, they are not economically efficient and feasible when transitioning to mass production. After you prove your product’s functionality, you need to proceed to its custom-designed PCB. A custom PCB designer will trim down all the unnecessary parts of a development board and help reduce the internal space required in the housing.

Customizing your PCB will also help you replace the electronic components with better alternatives that will streamline the supply chain and reduce costs. This stage is when you need the help of a prototyping and product development company with designers and engineers combined with access to top-notch manufacturing facilities that assist startups in developing prototypes of their ideas.

RELATED: How industrial designers and engineering services have influenced the product design world

3. Appearance model or “looks-like” prototype

“Looks-like” prototypes don’t have any functionality or electronics but showcase the final product’s appearance. These prototypes are considered the final result of the industrial design process where the outer feel and look of a product are made. Industrial design is particularly crucial for consumer products where the end-user has restricted interaction with basic electronics. However, the product’s usability and outer appearance are the primary factors in the customer’s buying decision.

An industrial designer works on the product’s user experience, aesthetics, CMF or color, material, and finishes. Mockups made of clay or foam are essential in testing ergonomics and refining the form of the product. Clay models are widely used in the automotive industry, while 3D-printed and foam models are more common for consumer product designers. Working on something tangible can help identify the real-life form and scale of the objects, which becomes more crucial for products meant to be handheld or worn.

It is also possible to generate a buzz with the appearance of prototypes, starting demo purposes, and early marketing campaigns. With the continuous advancements in 3D/CGI rendering software, you don’t have to make a prototype so that you can start your marketing campaigns. 3D rendering services now let you test ideas, raise funds, and begin your marketing campaigns earlier. Engineers and designers will ensure that you don’t market a concept that will not work in the real world. Using flashy renders to sell ideas that are impossible to make is a common mistake, but consulting professionals will help you avoid it.

RELATED: Top tips to create impactful prototype designs for company products

4. Alpha prototype (looks and works like)

Also called EP or engineering prototype, this is the stage where the looks-like and works-like prototypes are combined into one functional prototype with an appearance closely resembling the final product. It is also the prototype often used for demo purposes and crowdfunding campaigns such as Kickstarter. The custom-designed PCB and the custom-designed enclosure are integrated.

The housing will go back and forth between the industrial designer, who will finetune the form and aesthetics, and the mechanical engineer will integrate the electronics into the plastic shell while ensuring that the product adheres to engineering standards. The 3D documentation and files for prototyping using more innovative methods, such as 3D printing and CNC machining, are also prepared. However, at this point, the prototype is still not ready for mass production as it needs to be augmented for higher volume manufacturing processes such as injection molding.

This is where most Kickstarter projects fail since entrepreneurs underestimate the money and time needed to go beyond this phase and do the Design for Manufacturing (DFM) optimizations, prepare the molds, set up manufacturing, and get things together. Well-designed products consider DFM itself from the beginning for a smooth transition to mass production.

RELATED: 5 Tips to turn your idea into a new product design with prototype CAD services

5. Beta prototype

While Beta and Alpha prototypes are pretty similar in functionality and appearance, the main difference is that a DFM company has already ensured the general design has gone through DFM optimization with the beta prototype. These prototypes are also made using manufacturing processes closely resembling those used for higher volumes. Silicone molding is a frequently used method that looks like injected molded parts and produces 20 to 50 units. The enclosure design is also improved for the injection molding process, and the plastic parts go through mold flow simulations to guarantee that the plastic flow won’t cause problems in the mold later.

The engineering analysis involves considering structural optimizations, thermal simulations, and tolerance analysis. The beta prototype units are then sent to obtain different certifications for electronics such as CE, UL, FCC, Bluetooth SIG, RoHS, and others, depending on the specific product and the region where it will be sold. The prototypes also undergo validation and testing to ensure the product will function reliably and tolerate the environment it is made for.

RELATED: Top 101 engineering and mechanical design firms in the United States

- Engineering Validation Testing (EVT)

EVT ensures that the product will meet all functional requirements indicated in the Product Requirements Document (PRD) or specifications. The PCB goes through testing under EMI, power, and thermal stresses, and it will pass the EVT stage if the product still meets all functional requirements.

- Design Validation Testing (DVT)

DVT is a battery of tests performed on the prototypes to put them under significant stress. Depending on the specific environments the product needs to function within, the prototypes get tested for abrasion, burning, dropping from a particular height, submersion under water, and more. The prototypes must still have a reliable performance after they endure the tests and must not be worn out or damaged beyond satisfactory standards.

RELATED: Finite element analysis costs, consulting company rates & engineering services pricing

- Production Validation Testing (PVT)

Product validation testing is performed on the initial pilot run off the production line using the actual production tooling. These units are the ones that can be sold once they pass this stage. There is only one goal here: to make sure that there are no issues on the production line, that the workers have a good understanding of the assembly process, and that any inefficiencies in the production process are removed.

6. Pre-production prototype

The pre-production prototype is the closest you will get to copying the final product for scale manufacturing. This is the stage for cutting the steel molds using injection molding design services without making any significant changes to the product. Therefore, it is essential to freeze the design before this particular stage. The components made at this point are used to set the quality acceptance and quality control standards before the start of mass production.

The last Golden Sample serves as the reference for the ideal product quality. About five to ten percent of the overall manufacturing volume is used for PVT before proceeding to full-scale production. During the Beta prototype and pre-production stages, when the product is not expected to go through further changes, you will also need to start working on the product’s marketing materials and packaging.

RELATED: 3D printing technologies for modeling and prototyping

What tools do you need for electronics prototyping?

Prototyping has become more accessible than ever in the past few years. Listed below are some prototyping tools that will help get your ideas off the ground and, as the initial step, create a simple POC prototype. You can also use a professional rapid prototyping company to speed up, process, and develop a better-quality result.

1. 3D CAD software for custom plastic parts

In some instances, a custom enclosure design or custom plastic parts may be necessary; working with a professional is recommended in such cases. If you have spare time, you can also try to learn 3D CAD modeling software to design the parts by yourself. Professional 3D CAD software is not cheap, although a few options are available for free. Try to look for an affordable but more powerful option that is on par with more professional programs that are adequate for catering to the needs of most startups. Stay away from software that doesn’t have the precision expected in the manufacturing industry and is more suitable for CGI and artistic purposes.

2. 3D printers for plastic prototypes

FDM/FFF 3D printers using a plastic filament are available starting at $200, with different varieties available. Pick a 3D printer depending on your budget and requirements, such as the material you will be printing in, the available print volume, support, and others. It might be better to choose a more precise SLA printer if you need to create small parts, such as those for a wearable device. Most cities also have 3D printing services available to save you from buying and setting up your 3D printer.

3. Arduino

As mentioned earlier, Arduino is an open-source electronics product based on easy-to-use software and hardware. It consists of a piece of software and a physical programmable circuit board. The software or Integrated Development Environment (IDE) runs on your computer and is used for writing and uploading computer code to the physical programmable circuit board. There are various boards in the Arduino platform for different form factors and uses, the most popular option being the Arduino Uno. You can use the Arduino platform for multiple projects, such as blinking an LED or building a complex robot.

RELATED: The best PCB design software for electrical engineering professionals in 2022

4. Off-the-shelf enclosures

Housing is required to enclose the electronics. You can find enclosures in various materials and form factors suitable for multiple uses, such as handheld enclosures, IoT enclosures with touchpads, waterproof pens, and more. Several manufacturers also offer additional electronic enclosure design services, such as drilling cut-outs at specific locations on the PCB, different color and finish choices, printing the logo, and more.

RELATED: 3D Models of electronic enclosures by freelancer designers on Cad Crowd

5. Raspberry Pi

Raspberry Pi is a small and affordable electronic gadget. It is the size of a credit card and plugs into a TV or computer monitor using a standard mouse and keyboard. This small device allows people of different skill levels to discover computing. It can do everything desktop computers can, from word processing to making spreadsheets, playing games, browsing the internet, and even playing high-definition videos. Raspberry Pi can also interact with the outside world and be used in various projects that range from parent detectors and music machines to tweeting birdhouses with infrared cameras and weather stations.

Steps for developing new electronic and hardware products

Now that everything about electronic prototyping is out of the way, it is time to learn the steps involved in developing new electronic and hardware products. Software companies seem to be gaining all the attention these days, but it doesn’t need to be this way. All those modern-day miracles people know and love wouldn’t have been possible without PCBs and all the businesses that launch them in the market.

Before producing prototypes and planning the initial major production run, hardware startups must consider several crucial steps in launching their product in the market. These steps are meant to help you at the beginning of the product design stage and increase the chances of your new venture’s success.

RELATED: How to price a new consumer electronic product for profit on hardware manufacturing cost

1. Market validation

It is rare for an excellent design to sell itself, meaning you must spend time validating the market for your novel idea. There is more to market validation than estimating how many units you can sell annually. It all boils down to weighing the costs involved in producing and marketing products and how much revenue you can expect. The profit you make from this will then be invested into growing the business.

Aside from market validation, you must consider what startup you want to build. The number and range of products you plan to develop, the links between these products, and whether you will market to other businesses or end consumers will help determine the most suitable methodology for validating the market for your new products. These considerations will also decide on your overall growth and product development strategy.

RELATED: How much do manufacturing services cost for your company prototypes, products & new parts?

2. Drive innovation

There are two ways to drive new product innovation: demand-pull and technology-push. Regarding the latter, new technology gives an entrepreneur a chance to develop a new product that the market might not even know it needs or something that is not currently in demand. The former drive for innovation caters to a real need that the market demands and presently feels hasn’t been met. Your idea has immediate market validation if you are working on a demand-pull innovation. Sadly, there is a possibility that other entrepreneurs and companies have identified the opportunity as well unless your target is a niche market.

This competition means that the first company that used a 3d product modeling design company and successfully developed and marketed a functional product will have a first-mover edge. The first-mover edge is where you can make your product distinct from your competitors by targeting specific pain points in your target market. In contrast, technology-push innovation is not immediately evident to competitors, which also means that it might not be that obvious even to your potential customers.

The main issue is that you must spend more time educating and convincing your customers that your new product is a better solution than existing products. It is harder to validate technology-push innovation because of the less apparent demand for the new product.

RELATED: A guide to using plastic to prototype and manufacture your product designs

3. Estimate sales volume

One of the most critical points in market validation is estimating the potential sales volume and customer acquisition costs. If you are developing a piece of technology that upgrades an existing product, you will find it easier to estimate your product’s market according to the current sales volume. You can use search engine data to estimate advertising and marketing costs.

After you get an idea of the size of your potential market, you need to accept that you won’t be able to satisfy the whole market from the get-go. You have to set a realistic sales target after launching your product. Targeting a small portion of the market is wise, typically a few percent. Knowing the potential market size will also give you a good idea of your likely customer acquisition rate. This is where your search engine data can come in handy for estimating the costs of marketing targeted at your preferred market segment.

RELATED: Top 9 design engineering tips for reducing manufacturing costs on new product designs & prototypes

4. Define your design requirements

While going through the market validation process, getting better ideas of the demands in your market and how your new product should work is inevitable. After you validate your market and determine the functionality your product needs, it is time to define its functional requirements rigorously. These applicable requirements must specify the necessary capabilities for producing the anticipated user experience. Initially, it would be best to focus on what your product can do instead of how it is built. After rigorously defining the required capabilities and user experience, you can determine your device’s technical requirements.

This is when you need to think like an electrical engineering expert. You have to consider how the data will move throughout the system, how it will interface with the outside world, and how it will interface with other devices, for example. It will also inform the next step in the design process: to develop schematics and block diagrams for your product. Schematic creation is the first step to designing a PCB to support your new hardware product. It is also when you will choose the components in the system and begin to link them together to create your preferred functionality.

RELATED: Accessible design: better products for everyone

You will need to consider the specific design software you will use for making your product at this stage. Working with browser-based software is more cost-effective than desktop-based design programs because it offers collaboration, version control, and automated backup features in one platform. Your design requirements will be re-examined repeatedly and serve as the foundation for the other stages of the product development process. After getting a high-level view of the product design and its functionality, you can now proceed to develop block diagrams, hire a PCB layout designer, and have him design schematics for the new product.

5. Prepare for developing the electronics schematics

This is the point when you should translate your design requirements into actual functionality and engineer the different steps necessary to achieve the desired results. The block diagram must summarize every portion of the system regarding how the signals move between other parts of the product. The 3D CAD drafting professional shows every function in the system using blocks with clearly labeled outputs and inputs. This will help you visualize how signals move through the system and the components they will interface with. It is also acceptable to explicitly indicate certain parts in a block diagram, like microcontrollers that offer some data processing capacities.

RELATED: How to reduce painful product development costs for your company

When it comes to mixed-signal electronics design, you might want to separate the digital and analog parts of the system into various sections of the block diagram. Never lump digital and analog functionality into individual blocks because it will make translating information to an electronic schematic harder. The block diagram must stay as a living document while moving on to developing a schematic.

Once you begin to build your schematic, you might discover the need to alter your system’s original design, and as a result, your schematic will also need to change. Make sure that you keep detailed notes on why and how the block diagram was updated together with the earlier versions of it. This is essential if you are working with a team and want to ensure that the same information will be accessible to everyone.

RELATED: From idea to reality: turning your invention into a product

6. Create the schematics

The schematic is where you will assemble the parts into a complete system. Here, the engineering design company begins to design every aspect of the block diagram in different parts of the schematic. You can then define the connections between every functional block by making signal nets. This will let you enforce a certain level of organization in the schematic while building your system. Suppose the board features a microcontroller or any other programmable component. In that case, this is the best time to begin working on your code because you will have to test this before finalizing your layout.

Before you start your PCB layout, it is helpful to develop your ideal system on the breadboard to confirm whether your design will work as it is meant to. From the power integrity and signal integrity standpoint, your product may have some issues that you can only correct after you make an actual PCB layout. However, this will still let you test your design against your specifications and ensure it will produce the expected functionality.

RELATED: Product simulation and analysis: why it’s worthwhile

If any of the functionality tests fail, it is then time for you to update your hardware design or your embedded software, or even both. You have to seriously consider the specific components you want to include on the board and other suitable replacements in case it is impossible to source your preferred ones. It is also a wise idea to check the availability of components through different major contributors before you get too deep into the design. If you wait until you finish your design and include a component that is obsolete or has a long lead time, you risk a significant redesign after you start getting ready for production.

7. Proceed with the PCB layout

The final design step the electronic device design professional must complete before getting ready to develop your prototype is creating your PCB layout. If you have produced your schematic according to the guidelines mentioned above, it will be easier for you to create your layout. You can cluster all the critical components into groups in the schematic according to the functional blocks, and doing so will let you focus on the block’s layout in the CAD software.

RELATED: New manufacturing materials: expanding the possibilities of product design

After you individually finish every block, you can begin to route them together to form a fully connected system. There are still several other design aspects to consider, such as your grounding strategy, the number of layers on the board, your routing topology, and the need for any thermal management measures such as heat sinks or thermal vias. If you are a professional engineer, you likely already have the necessary experience to make all those critical design decisions and develop a product that works in various conditions. If not, then you still have some studying to do.

You can work with an online platform that offers all sharing and collaboration features in a GitHub-style environment. This will let you get the best out of open-source projects and gain valuable insights from other people’s work. It is also a great way to earn some perspective on how to lay your board. Remember that nothing is wrong with studying other people’s designs. They are available in the first place for others to use, so make sure you take advantage of them and acquire new learning with their help.

What’s Next?

Your product development journey is not yet over just because you have finished working on your PCB layout. Before proceeding to the manufacturing stage, you must check your design against the standard constraints and rules on electronics design. The said rules are put in place to ensure that your new product will work exactly how you plan it to from the signal integrity and power integrity standpoint. These will also help guarantee that your board will be manufacturable in the first place. A design for manufacturing and assembly professional has the necessary expertise to assist you. You can also work with a simulation tool to help you diagnose any issues with signal integrity in your design before you produce the prototype.

RELATED: A product designer’s guide to designing for manufacturability

The Bottom Line

You can expect to encounter plenty of production and design challenges as you turn your new hardware product idea into a prototype and, ultimately, a finished product. Using the right design tools and the proper knowledge, you can soon bring all your innovative ideas to life that will set your hardware startup or design company apart from the rest.

How Cad Crowd can assist

Our electronics design services will allow you to produce products that meet your company and client’s expectations. Regardless of where you are in the process, our team wants to help you get the design assistance you need. If you are ready to hire an exceptional designer, we invite you to request a free quote today!