Unless you’ve been living under a rock for well over a decade, you likely own some sort of smart device. Your phone is smart, your TV is smart, your watch is smart—even your fridge and oven are smart.

The age of technology has swept over the world in an ever-increasing Moore’s Law driven frenzy, with new and faster devices offering functionality people would never have imagined even fifteen years ago, let alone fifty. A common but mind-blowing fact is that there is more processing power in your phone than there was in the computer that sent the initial astronauts to the Moon and back.

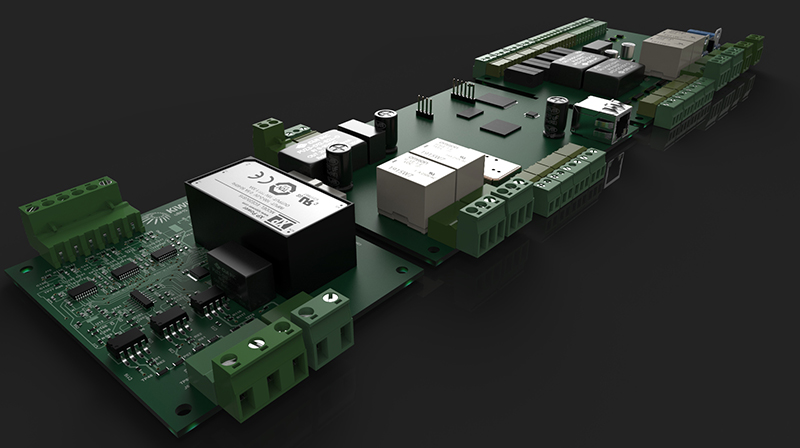

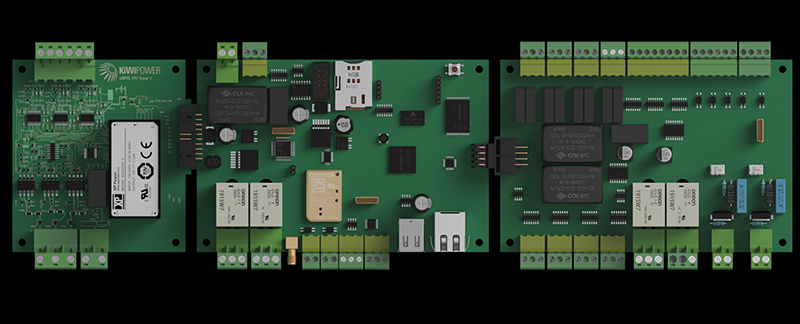

The thing that makes all of this technological development possible is the rapid advancement and implementation of PCBs. A PCB, as you likely know, is a printed circuit board. These circuit boards, or motherboards, or computer chips, or whatever preferred terminology you want to use, carry all of the logic functions of a device and help carry out the instructions of pieces of software.

Without PCB design services, no digital computing is possible in any shape or form. These took over after transistors and large computer chips became impractical, and developments in production methods and materials science allowed engineers to develop smaller and smaller microchips. Eventually, it became possible to print out a standard circuit board in a small footprint that you can use in a computer, car, or oven.

Designing a PCB Product

Designing a product with a built-in PCB can be a challenging task, but the result can be an eye-opening device that changes the lives of people everywhere. Just think of the smartphone—people can hardly function without one today, but most had never even imagined the concept back in the early 2000s and before.

Whatever new product you’re dreaming up may be the new groundbreaking advancement that changes lives throughout the world. Regardless of what you’re planning to create, there are several steps you can take to make your life more comfortable and reduce your stress.

Let’s take a look at some of the things you can do to reduce your burden when designing your new PCB-integrated product for manufacturing and working with a drafting services expert.

Tips When Designing a PCB-Integrated Product for Manufacture

1. Know Your Functionality ahead of Time

The most crucial aspect of your PCB design is its functionality. Your product will have a purpose, and not only that, it will be designed to accomplish specific tasks based on the software and the circuitry that it contains. Knowing this information upfront will make your task a lot easier.

Of course, I’m sure you have a plan for what the product will accomplish, such as automatically letting your dog into the backyard on a programmed schedule or allowing you to flip a hamburger remotely, but there is a bigger picture. What steps need to happen for this device to accomplish those tasks? Are there side functions that you want it to have, and are there secondary actions that are necessary for the completion of the more significant task?

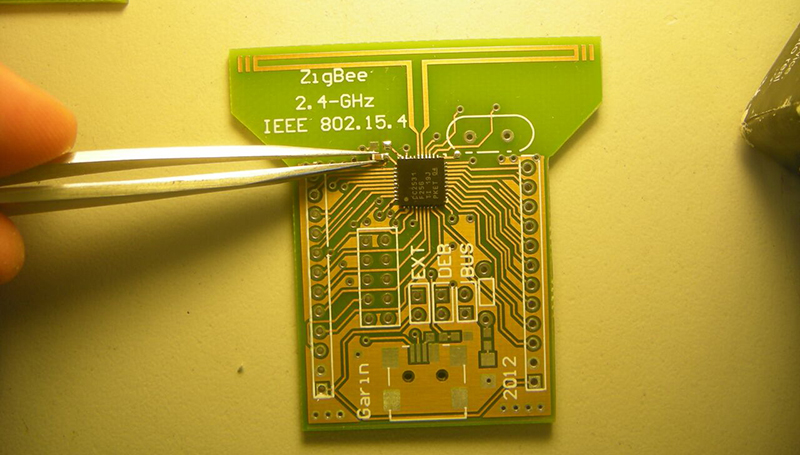

For instance, if you want a device that can work over long distances, you will need circuitry that can incorporate a wireless connection or Bluetooth. For example, your remote burger-flipping device will likely need a Bluetooth connection as well as a circuit board that can operate variable levers and motors.

Or, for your dog escape timer, you will need the functionality of a clock as well as the typical circuitry. Most often these days, also, these products have programmable inputs, a user interface, and perhaps even smartphone compatibility. The clock is a side function that needs to be accounted for to ensure the proper functioning of the device.

The best way to figure out what is needed for your product design service to get started is a flow chart or function map. Plot out the least divisible logic steps for the function of your product to see what process is needed to get it from input to end state. For instance, assuming you have put in the information about what time your dog should be let out, it needs a timer circuit to count to this time, which, when reached, would need to relay a signal to a mechanical device that would open the door.

Depending on certain other conditions, it should use predetermined logic to shut said door. You can plot out other functions, like an integrated sensor that would alert you if the dog has returned into the house or an additional setting that could close the door automatically if it was left open for too long or on accident.

Once you have plotted out the functionality, you can begin to piece together what is needed from a hardware standpoint. The flow chart will serve as the basis for the logic that is written into the device itself, and you can use it to choose from a variety of PCBs that meet the functionality requirements.

You can still create your product without the flow chart, but this step will streamline everything you do from here on in, so it is very helpful for you to get the logic pieced together in advance, to make your life easier through the whole process.

2. Standardize Things as Much as Possible

Whether you have looked for it or not, similar products likely exist. As a wise man said, “there is nothing new under the sun.” Your product does not exist in the state it does in your mind, but there are similar things out there, and there are also many components out there that are predesigned.

Most of the circuitry that you are seeking exists. In fact, it is entirely likely that all of it exists and can just be cobbled together to create your Frankenstein-esque monster of a product (don’t worry, you can streamline it and make it look pretty).

That is the inherent beauty of printed circuit boards. They are designed as an avenue (or conglomeration of avenues, more accurately) through which logic can flow and act using the movements of electrons. To that end, they are much like the grid system of New York’s streets. That same system can be traversed into trillions of different patterns, stopping at different sequences of places and ending up at different destinations every single time without duplication.

Because of this, a standardized PCB exists to fit your needs. A simple Google search will reveal a number of products that line up with the functionality you are seeking, and there is a high probability you can walk down to your local Radio Shack and find some of those boards in person.

By standardizing these parts, a consumer product designer does himself a number of services. First of all, you have removed one item off your to-do list. You no longer need to design a circuit board. You’ll also decrease your costs because a specially designed board is bound to cost a lot more than one that’s sitting at a nearby electronics store waiting to be picked up.

Third, it makes repair and replacement much easier. If you have a standardized board sitting inside your product, either when it’s in development or sitting on a store shelf somewhere, any malfunction can be quickly and cheaply resolved.

This will reduce your lead times and expenses, particularly when you are first making the product and will likely break a few or have to redesign it several times. Save yourself some hassle and standardize the boards inside, and let the logic do the heavy lifting. It’s much easier to change a few lines of code than it is to redesign an entire circuit board and then replace it inside of a product.

3. Use an Experienced Designer

Here’s the biggest point of all. You need to find yourself an experienced engineering design service, both in terms of hooking up and implementing a functional PCB and also in terms of writing code and logic to make the product work. You may be an accomplished computer scientist for whom this is a simple and straightforward procedure. If that’s the case, go ahead and tackle it.

Wherever you go to find one of these designers, make sure you locate one who knows their way around the languages you plan to use and preferably has some experience in the industry you are planning your product for. There are very detailed and specific requirements, for instance, for a security product, and they are very different from those required for food preparation.

In fact, it behooves you to find this individual sooner rather than later because they will know the intricacies of the logic. They can help you in the planning and plotting process to understand what needs to go into the function map because there are likely many intermediate steps that you will have forgotten that require additional programming or circuitry. Either way, they are an incredibly valuable resource, and they will likely be your lifeline throughout the development process.

Find someone you trust and can work well with, and you will have a winning combination – particularly when they help you with the other steps of this process (because they undoubtedly know what standardized parts exist and can help you select the necessary items to make the best possible product).

Cad Crowd’s Freelance PCB Designers Can Help

Cad Crowd has a large selection of designers and freelance electrical engineers who are skilled with electronics, logic, circuit design, and much more – on top of their skills in drafting and engineering design, all of which are very useful in crafting a potential product.

If you’d like to entrust your project to them, take a look at how it works. Or launch a design contest and have our freelance PCB designers present their concept ideas to you.