CNC machining, or computer numerical control machining, is a production process that utilizes computerized controls to operate and manipulate machine tools. These machine tools include lathes, mills, routers, and grinders, and they can accurately create complex parts and components from various materials.

CNC machining was once a production process exclusive to multinational businesses and giant corporations. However, as competition in the business world intensifies, small to medium-sized companies are increasingly adopting CNC machining. Additionally, machines as a service (MaaS) are gaining popularity, like software as a service (SaaS).

Outsourcing CNC machining services to providers offering prototype design engineering services enables companies to achieve more while reducing costs. The emergence of CNC MaaS introduces a broader range of options for businesses, although this variety can pose challenges in identifying the best provider for specific needs.

This article will discuss how outsourcing CNC machining services for your company’s prototype design is beneficial, explain why CNC machining is a practical choice for prototyping, and guide what to consider when selecting a provider of prototype design engineering services.

Why use CNC machining for your prototype design?

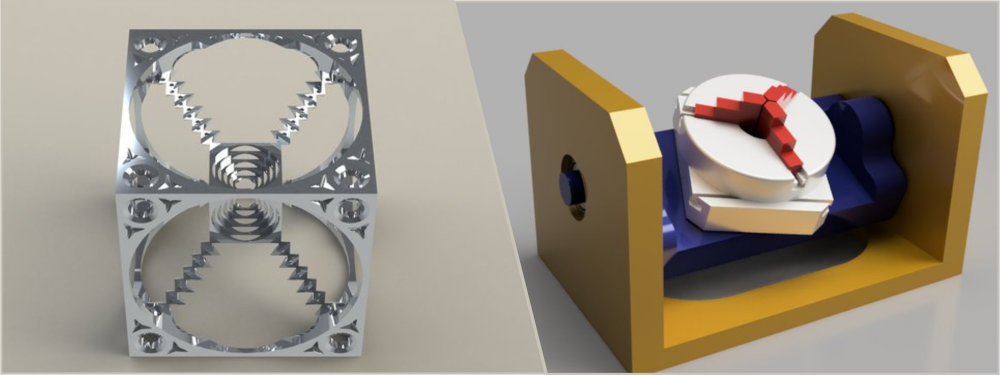

While various methods exist for prototype design, CNC machining stands out as the most effective. CNC machining allows for digital product design, software inputting data into the computer, and directing the CNC machine’s actions.

By employing CNC machining, common human errors are eliminated, significantly improving the efficiency of the prototyping process. Additionally, freelance CNC programmers can assist industries in transforming concepts into detailed technical drawings, enabling the production of flawless parts with each iteration.

RELATED: CNC Programming Costs & CNC Machining Service Rates for Companies

Here are other reasons why CNC machining and CNC programming services are ideal for your prototype design needs:

1. Accuracy

A reliable CNC machining service consistently achieves appropriate tolerances for extended production runs. They may also use a different machine when running a tighter tolerance and have precise cuts for shorter runs to ensure accuracy at all times.

2. Variety of materials to choose from

Reliable CNC machining service providers, including CNC Design Services experts, utilize CNC machines adaptable to various cutting materials to accommodate customers’ diverse prototyping needs across different industries. Today, customers often prefer to visualize their prototypes in multiple materials, and CNC machining provides substantial advantages. With CNC machining, it is feasible to prototype the same design using materials such as steel, aluminum, or rigid plastic, requiring only minimal adjustments to the feed rate and speed of the cutting tool.

3. Easy modifications

When customer requirements and job demands call for adaptation, prototyping often requires modifications, adjustments, or a complete overhaul of the original design. CNC machining experts, operating CNC machines are well-equipped to manage these changes. They can quickly alter the G-code with just a few keystrokes and seconds. Customers appreciate this ease of modification because it allows them to test multiple iterations and observe the results in real time. CNC machining experts can significantly reduce costs and time by altering the G-code and making refined tweaks during prototyping.

4. No need for fixed tooling

Only a handful of tools are required when using CNC machining for prototyping—specifically, the metal cutting inserts found in the spindles of lathes and mills. CNC design services designers have access to different sizes and shapes of cutting blades or inserts, which are versatile and useful for various functions, regardless of the material required for prototyping. Additionally, these components can be swapped out in the machines with remarkable speed. By minimizing the need to change machines or swap out parts frequently, CNC design services designers can effectively cut costs associated with the prototyping process.

5. Speed

CNC machines run on a set of CAM and CAD-programmed codes. CAD software is responsible for designing the assemblies and models that the CAM software will translate into M-code and G-code that drive the tools of the CNC machine to transform the designs into actual physical parts. After the CNC programming designers have programmed the G-code, the lathes and mills can cut through anything you need with exceptional speed to turn the raw material into finished parts in seconds.

RELATED: The Advantages and Disadvantages of CNC Machining for Prototype Design

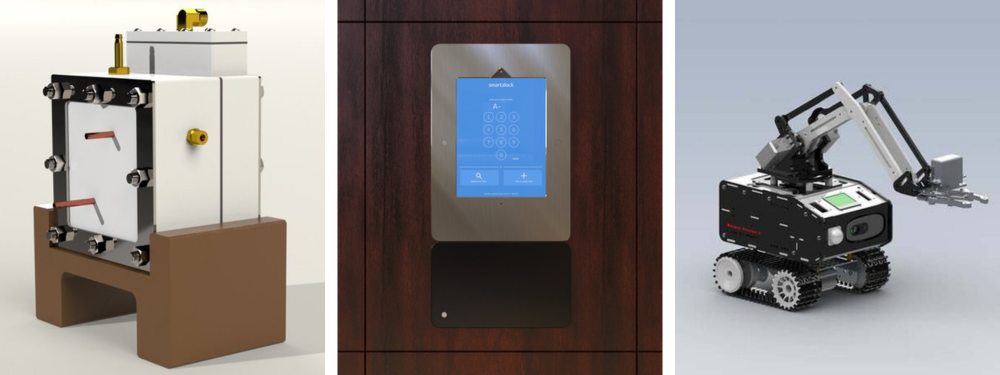

Why outsource your CNC machining needs

Save on costs

CNC machines are expensive and require specialized tools and training for proper operation, so small businesses often find them beyond their financial reach. Additionally, CNC machines are large, and companies must allocate sufficient space in their workshops to accommodate these massive pieces of equipment.

By outsourcing your CNC machining needs to CNC machining experts who offer prototype design services, you can alleviate concerns about the costs associated with owning, housing, and operating such equipment. This approach helps you save money and allows you to focus more time and resources on your critical business operations while benefiting from the expertise of professionals in prototype design services.

Improve production process

CNC machines are advanced and state-of-the-art equipment capable of immediately enhancing both the efficiency of the production process and the quality of the parts produced. These machines offer convenience, especially when repetitively manufacturing similar designs. Rather than incurring tooling costs for each production run, you can outsource these needs to custom product packaging design services, saving time, labor, and money.

Remember that CNC machine operations require continuous supervision to guarantee the production of high-quality components and parts. Outsourcing your CNC machining needs reduces the manual labor burden on your employees. As a result, more focus can be placed on other important tasks and roles within your business, including collaborating with custom product packaging design services to enhance the presentation of your products.

RELATED: How Much do Manufacturing Services Cost for Your Company Prototypes, Products & New Parts?

Wide-ranging capabilities

Flexibility is a key advantage of outsourcing your CNC machining needs, especially when working with design for manufacturability (DFM) experts. In-house CNC machining can have restricted capabilities, particularly when launching new products. Additional equipment investments may be necessary to meet growing demands and scale production.

However, these limitations can be mitigated by outsourcing your CNC machining needs to specialized manufacturing companies, including DFM design services. These companies have access to a wide range of CNC machining equipment, and their capabilities extend beyond the sheer number of CNC machines. In addition to offering various materials and file formats, they are equipped to handle secondary processes such as heat treatment and anodizing, providing comprehensive manufacturing solutions.

RELATED: What are Industrial Design Rates & Costs at Product Design Services Firms?

Considerations for Selecting a CNC machining service provider

- Know-how in targeted industries

The best CNC machining programming and prototyping services provider can easily cater to your demands for quality because they have the experience and expertise in your industry or other related industries. Working with a CNC machining provider who understands your specific industry is critical, and it will allow them to offer you the necessary targeted services for improving your product.

It also ensures that you will get the custom parts whenever needed. These providers will also be more proactive in identifying and fixing issues before they become serious problems. They should also be familiar with the compliance requirements of your industry. Feel free to request a list of services or case studies to help you determine if the company can cater to the needs of your business and keep up with them as you grow.

- High-caliber technicians and high-quality equipment

The best provider of outsourced CNC machining services has the latest tools and equipment, which lets them provide high quality and precision when manufacturing machined components and parts. These providers are also expected to have highly skilled and professional technicians who can competently use and supervise the equipment and tools to develop your products. Adept technicians can identify quality concerns with your parts before production begins.

- Proven track record

It is always worth it to invest in high-end machining. But while you might be ready to spend on quality services, you must also research and decide if a provider will be worth your money. The best way to reach this decision is to check the company’s track record and ask for the provider’s history. A machining company in business for decades has already serviced several companies and can handle all your needs.

You can also take a look at how the provider works. Do they have prompt deliveries? You also need to check the stability and financial health of the provider and look for customer testimonials and reviews. A trustworthy CNC machining provider will never have second thoughts about giving you referrals to back up the quality of their services. While many CNC machining companies claim to be the best, it is a different story if it comes directly from a client. Doing your homework will help you save headaches and time in the long run.

- Accessibility and transparency

Choosing a CNC machining provider involves establishing a partnership that benefits or hinders your business. The ideal partner communicates how they contribute to your success and openly defines their working relationship with your business. When seeking a potential partner for your CNC machining needs, consider those who prioritize effective communication. The provider should respond promptly to your inquiries and offer multiple communication channels for easy accessibility.

It’s also essential to seek customer-focused providers that offer prototype tooling and manufacturing services, pay extra attention to your products, and prioritize quality. Look for providers willing to deliver value-added services, demonstrate flexibility in accommodating change orders, and are readily reachable. Clear and specific expectations should be established during the selection process, and concrete terms and conditions should be developed.

The CNC machining provider should know what to expect as the partnership progresses, have defined responsibilities, and embrace a positive win-win mindset to ensure a mutually beneficial collaboration.

RELATED: Top Tips to Create Impactful Prototype Designs for Company Products

Summary

Outsourcing CNC services for prototype design offers benefits. CNC, a high-tech process, creates precise parts and is accessible to smaller businesses via MaaS. Outsourcing to prototype design engineering services brings cost savings, improved production, skilled techs, and equipment, enhancing quality and flexibility while reducing labor.

Selecting a CNC provider involves assessing industry expertise, equipment, track record, accessibility, and customer focus. Value-added services like prototype tooling and manufacturing are beneficial. Outsourcing to DFM and PLC programming specialists drives efficiency and innovation.

How Cad Crowd can help

Cad Crowd connects companies with top freelance engineering design services for CNC machining, prototype design, and DFM needs. The platform offers access to a network of pre-vetted CAD designers and CNC experts for custom projects and collaboration. By using Cad Crowd, companies can enhance product development, optimize production, and achieve cost savings while maintaining quality standards.

Cad Crowd’s commitment to flexibility, innovation, and customer satisfaction makes it a valuable partner for businesses looking to elevate their CNC machining and design capabilities. Request a free quote today to explore Cad Crowd’s offerings.