There are many new technologies in the world that are transforming the way industries operate. One ground-breaking technology that is making waves in design and manufacturing is 3D printing.

In recent years, 3D printing has experienced a boom. It has come into the limelight and is now becoming accessible to a wider audience. In this article, we look specifically at how 3D printing services can be used to create product prototypes.

The Explosion of 3D Printing

In the last 10 years, 3D printing has exploded onto the scene. The concept and process of 3D printing

In the 2010s, new techniques for additive manufacturing and 3D printing processes were developed. Affordable 3D printers came into the market and allowed an unparalleled level of usage and creativity for the process – home users can now even purchase 3D printers. Furthermore, complementary technologies such as CAD have also improved greatly, which allow 3D printing to be used for a wider scope of possibilities.

Industries That Use 3D Printing

To demonstrate just how popular 3D printing has become, we have listed some industries that are currently using this technology:

- Architecture

- Construction

- Education

- Food

- Medical Science

- Pharmaceutical

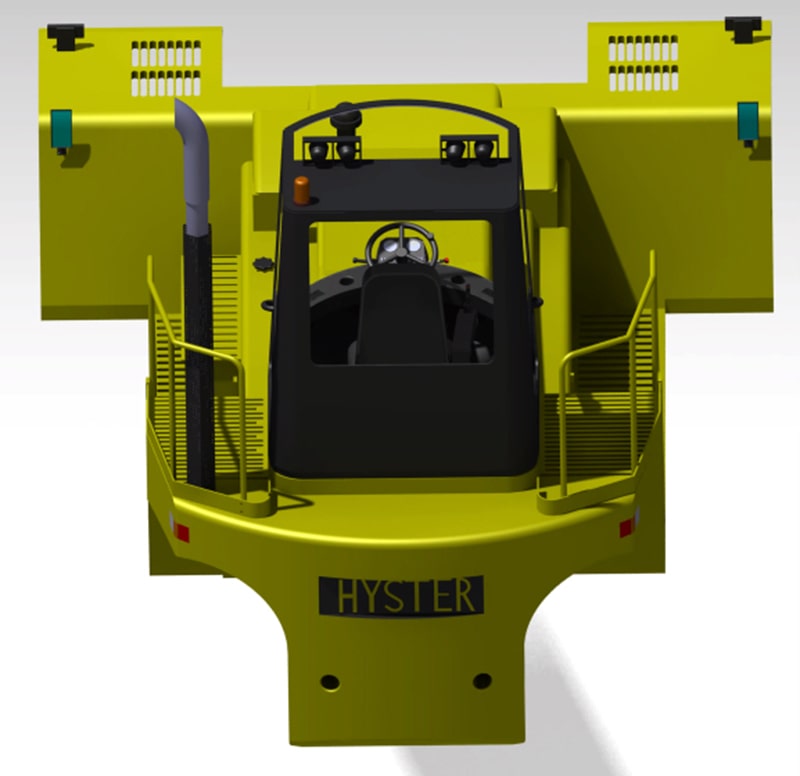

- Automotive

- Art

- Furniture

- Firearms

- Aviation

As you can see, 3D printing really does have a wide variety of uses – the list above is just the tip of the iceberg. In the aviation industry, for example, GE Aviation and Boeing are both looking at 3D printing to create aircraft parts. Moreover, the automation industry has actually pioneered the use of 3D printing – it has been used to improve new prototype design and testing stages to reduce costs for the end consumer.

In medical science, 3D printing is being used to create and design items such as prosthetic limbs. The process is much quicker and cost-effective than traditional production methods. Furthermore, limbs can be easily customized to suit the patient’s needs.

The main point is that 3D printing is becoming increasingly viable. It can transform the way we do business and greatly improve many aspects of the design and production process.

Things to Consider When Looking at 3D Printing for Prototype Creation

When using 3D printing, there are many considerations to make. Creating a prototype is not just a case of purchasing a 3D printer and starting work. The following are some considerations that you must look at before starting the design and production process:

Printer Type and Cost

First and foremost, you must consider the printer itself. High-quality 3D printers are not cheap. 3D printers come in many shapes and sizes. You can purchase small 3D printers that can fit on your desk. Alternatively, you can buy large 3D printers that are suitable for factory installation. Consider the following when choosing a suitable device

- Cost

- Size

- Method of 3D printing

- Maximum build volume

- Available print materials

- Warranty and customer support

CAD File Formats

When creating prototypes, you work with a product design firm to develop 3D file to extrapolate the design from. There are numerous 3D printing file formats available. You should check what file formats the printer can support. Furthermore, you should look at what programs you have available to design the 3D printing files. The following are some common file formats:

- STL (Stereolithographic)

- OBJ (Object files)

- AMF (Additive manufacturing format)

- 3MF (3D Manufacturing format)

Materials for Production

Finally, you must also consider the different materials that can be used. What is the prime material that you will use for the production of prototypes? Can your 3D printer support this material type? There is actually a wide range of different materials that can be used for 3D printing. We have listed some common forms below:

- Nylon

- Resin

- Stainless steel

- Gold / Silver / Precious metals

- Ceramic

- Gypsum

- Plastics

6 Ways to Utilize 3D Printing to Create a Prototype

Prototypes are used to test products. A prototype is built once the initial designs and specifications have been created. Businesses use them to test the actual functionality and viability of their products. A prototype can show up potential flaws and can show if a product will actually work.

Prototypes can be refined and re-designed multiple times – this is why the process must be cost-effective and efficient. 3D printing design can indeed improve efficiency and turn the prototype creation process into a streamlined operation. We have listed six particular details below how 3D printing can be used to make a prototype for your new product design:

1. Improving Innovation in the Creation and Design P

3D printing can actually improve efficiency greatly. It can remove much of the constraints that the traditional production process

This, of course, is time-saving, but it also means that designers can concentrate on the actual prototype and design itself – they do not have to worry about configuring the prototype or trying to build it. They can create multiple designs and play with new features and design elements without adding much time to the whole production process.

In short, the lack of constraints and limitations mean that engineers have more time to look at the design itself. They have much more freedom which ultimately results in innovative product design.

2. Overcoming Difficulties in Both Design and Manufacturing

During the design process and manufacturing of prototypes, problems often arise. If issues are found with the design, the process to make changes and improve the prototype is time-consuming and costly. When using 3D printing, small changes can be made with ease. Furthermore, the design itself can be modified easily using 3D printing programs.

This means that any errors and difficulties found can easily be overcome. Obviously, 3D printing still has its own challenges, but these are minimal in comparison to traditional manufacturing.

3. Improve Efficiency during the Prototype Stage

It is widely known that standard manufacturing processes are not hugely efficient. It is estimated that

This 25% can result in reduced production and ultimately reduced revenue and sales. Effectively, one out of four processes are not contributing to the actual production process, or are being under-utilized.

This is often the case because specialist processes are used that lack flexibility and versatility. Die casting and injection molding, for example, require specialist machinery and processes to operate. Although 3D printing is specialized, it is also versatile. A 3D printer is not constrained to one type of product or one material – a single 3D printer could be used to develop 15 completely different prototypes for example.

By using 3D printing to develop prototypes, you can greatly improve your efficiency. You can streamline the prototype development process which can ultimately improve manufacturing times and increase your overall output.

4. Reduce Wastage of Materials, Labor, and Time

Throughout the world, companies are attempting to be efficient and reduce their wastage. Acting responsibly and environmentally friendly is a big plus and can help give companies a competitive advantage. It is also a great way to save costs and improve revenue. 3D printing can actually help reduce wastage of labor, time and materials.

Did you know that the benchmark percentage for manufacturing wastage is 21%? It is believed that 3D printing can actually reduce this to below 10%. Furthermore, when using 3D printing to product prototypes, you can significantly reduce your carbon footprint.

How is this achieved? Firstly, the 3D printing process is less energy intensive and requires less power to operate. Secondly, you use fewer materials to build your test designs. Thirdly, designs can easily be modified and re-created using the 3D engineering software, which can reduce labor costs.

5. Improving Basic Design Mechanisms

Traditional manufacturing and prototype development had limitations. Firstly, the traditional process was split into different stages. Secondly, the actual prototype was usually created in a different material than the actual end product. This meant that inconsistencies often arose and that the prototype wasn’t a true reflection of the product itself.

3D printing can improve the basic design process and mechanisms. The prototype can be developed in the exact same material as the end product – this can, of course, improve accuracy.

Furthermore, the actual design process is streamlined – a digital thread can be used at various stages which improves cohesion. There is no need to create different models for each stage of the process – an engineer can effectively design one model and take it through the different stages right up to the actual 3D printing process.

Furthermore, the actual design process is streamlined – a digital thread can be used at various stages which improves cohesion. There is no need to create different models for each stage of the process – an engineer can effectively design one model and take it through the different stages right up to the actual 3D printing process.

6. Provide Manufacturing as a Viable Service

Manufacturing as a s

3D printing can facilitate this flexible and robust business model. A company could install several 3D printers, For example, which would allow them to pump out prototypes and take on various clients from different industries. Rapid tooling services are the way forward and diversification led by 3D printing is the key – this all starts at the prototype stage.

Companies can basically use 3D printing to diversify their product catalog and appeal to a much wider market. They can create a plethora of 3D prototypes and find innovation in much less time.

3D printing is certainly an interesting avenue to explore. As technology improve, we can expect the use of this process to increase. Furthermore, we should see more complex designs being created as software, material processes, and the printers themselves are developed.

Cad Crowd’s freelance specialists have the knowledge and experience to help you with 3D printing services and SLA 3D printing that you may need. Check out how it works or get a quote.