When it comes to new prototype design, a lot of people think of it merely as a pre-production sample which often has very limited features and functions compared to the actual product to be released to the market. The key term here is “pre-production” in the sense that a prototype is an unmistakable representative of a soon to be mass produced artifacts. From the designer’s perspective, however, a prototype should be a working model, equipped with the same set of specifications as planned for the final product.

Before any product reaches the market, designers have to be sure that it’s both technically feasible (e.g. design via CAD services) for production capabilities on the manufacturer’s side and financially viable for investors and consumers, as well. A prototype will help designers and manufacturers to do the following:

Perform a preliminary test of performance and design

The idea the prototype is built from may seem flawless, but you must remember that everything is still theoretical until you start creating a physical manifestation of it. Although no one expects to encounter problems with their prototype, there’s always the possibility that something will need to be altered so the end product can be even better. In other words, a prototype serves not only as a sample of the future product, but also as a foundation on which further refinements and improvements are made before the product reaches the production line.

The idea the prototype is built from may seem flawless, but you must remember that everything is still theoretical until you start creating a physical manifestation of it. Although no one expects to encounter problems with their prototype, there’s always the possibility that something will need to be altered so the end product can be even better. In other words, a prototype serves not only as a sample of the future product, but also as a foundation on which further refinements and improvements are made before the product reaches the production line.

Experiment with various materials

Every product from any category is made of raw materials or a combination of several different materials. A prototype – because it’s produced on a small scale – gives designers the chance to experiment with various materials and to figure out which materials work best. You might want to use metal materials and you can build two or more prototypes with different types of metals, such as stainless steel and aluminum, to test them out. In general, each material has its unique characteristics, which may or may not be suitable for the product you’re trying to create.

Make a definitive description of your product

When you’re working with a team, a prototype makes it easier to explain what you’re trying to accomplish and how the product will help you to achieve those goals. It can also be the perfect tool to demonstrate features and functions.

Promote to manufacturers

Assuming you aren’t working with a manufacturer from the beginning, your product prototype helps you to build a convincing case on why manufacturers should be interested in collaborating with you. Bringing a prototype to a marketing presentation also creates a professional impression, encouraging others to take you more seriously.

A prototype is often regarded as the point where the design process is reaching its end while production is about to begin. Designers have gone through a lot (as they should) when they arrive at the prototyping stage. The process starts from the moment you conceive the idea until you are finally able to materialize it. You can divide the process into three major steps as follows.

1. Brainstorming

Once you have a full understanding of every aspect of the product – its purposes, how it achieves them, and the way it looks – the real brainstorming begins. You can think of the idea as a broad concept but without any specific information attached. In the beginning of the brainstorming process, there may still be important details missing from your concept design, like colors, textures, materials, size, and why your product is different from others already in the market. It takes time and work to do proper research and figure out the best approach to transform your idea into reality. You’ll also need to be sure that your target consumers will be interested in buying the product.

Once you have a full understanding of every aspect of the product – its purposes, how it achieves them, and the way it looks – the real brainstorming begins. You can think of the idea as a broad concept but without any specific information attached. In the beginning of the brainstorming process, there may still be important details missing from your concept design, like colors, textures, materials, size, and why your product is different from others already in the market. It takes time and work to do proper research and figure out the best approach to transform your idea into reality. You’ll also need to be sure that your target consumers will be interested in buying the product.

As a rule of thumb, the most compelling reason for consumers to make a purchase is that the product solves a long standing problem or improves their quality of life. Take watches as an example, a wristwatch allows people to tell time anytime, anywhere, but which parts of a watch are compelling enough to make people choose it over the alternatives? Is it the second hand, the dial, the date position, the movement, or the craftsmanship? The same question applies to all other products.

It’s called brainstorming because you’ll come up with hundreds, if not thousands, of ideas this way. Write the ideas down, preferably in an organized way, so you can backtrack easily if necessary. You need to know why you prefer one idea over another and how you came to that conclusion. That being said, market research is arguably the longest part of brainstorming because you need to know whether your ideas have been attempted before or if someone else already has the patent rights for the product. Once you’re sure the product will sell and that the product is unique move on to the next step.

2. Rudimentary product sketch

Based on your notes during the brainstorming sessions, draw a simple sketch of the product that describes its features, design, possible materials, functions, and any other related details. If the product has a lot of mechanical or electrical components, it’s necessary to include information about the parts used and where to get them or how to build them. For the sake of having detailed descriptions, draw multiple sketches from various angles. A simple sketch is easier and quicker to draw, which means you’ll also have an easier time making alterations in case you have some new ideas to implement.

Once again, make sure the sketches are neatly organized as these rudimentary drawings are indispensable documentation when you are filing the patent for the product. As a precautionary measure, have a trusted colleague sign the sketchbook to prove that the time and dates are indeed accurate. It can even be strong evidence if, at a later date, you need to defend ownership of intellectual property.

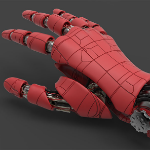

3. Digital 3D prototype design

Simple sketches of your ideas aren’t enough if you want to get more serious about developing a prototype. In addition to those rudimentary drawings, make an effort to create a digital prototype. For that you’ll need a computer and 3D CAD software (e.g. SolidWorks Engineering). Unlike your sketches, which provide a description of your product in 2D, a digital prototype offers a more realistic perspective of how your product will look and perform.

Simple sketches of your ideas aren’t enough if you want to get more serious about developing a prototype. In addition to those rudimentary drawings, make an effort to create a digital prototype. For that you’ll need a computer and 3D CAD software (e.g. SolidWorks Engineering). Unlike your sketches, which provide a description of your product in 2D, a digital prototype offers a more realistic perspective of how your product will look and perform.

A digital prototype is often interactive. You can rotate, flip, and manipulate the model in any way you see fit. It allows you to change the color in an instant, zoom in and out, and see how it performs through simulations. It’s also possible to use a set of data points during the test such as heat, pressure, speed, weather, depth, altitudes, and anything else relevant to the use of the product in real situations.

Creating a digital prototype is a crucial part of the manufacturing process. The physical prototype is based on the data and imagery available in the digital format. Every single detail must be correct by your specifications. Unless you have the necessary skills to create digital prototypes, this task is best left to professionals. Before you hand over the sketches to a design agency, make sure all parties are willing to sign a non-disclosure agreement to protect your intellectual property.

Depending on the complexity of the product, creating a digital prototype is as far as the product will develop before moving into the manufacturing stage of the process (e.g. building a physical prototype of a car engine or a building isn’t financially viable or reasonable to undertake). The good thing is that well-crafted 3D renderings should deliver hyper-realistic imagery of the product to the point where physical models are not required for presentation and testing purposes.

4. Physical prototype

Not every product requires a physical prototype to be made, but it would be a great help to your marketing efforts if you can bring a prototype to manufacturers or investors.

One of the most common tools used for prototyping in today’s manufacturing landscape is the 3D printer. Thanks to market competition and technological improvements, prices for the device have gone down quite a bit (especially for consumer-grade models). Simple products such as coffee mugs, flip-flops, action figures, and anything else with few moving parts are relatively easy to print. Even a handyman or machinist should be able to help you to create simple prototypes. For more complex products with a lot of mechanical or electrical components, a 3D printer may not be enough.

One of the most common tools used for prototyping in today’s manufacturing landscape is the 3D printer. Thanks to market competition and technological improvements, prices for the device have gone down quite a bit (especially for consumer-grade models). Simple products such as coffee mugs, flip-flops, action figures, and anything else with few moving parts are relatively easy to print. Even a handyman or machinist should be able to help you to create simple prototypes. For more complex products with a lot of mechanical or electrical components, a 3D printer may not be enough.

Turn to online platforms (forums and crowd sourcing) to tell the world about your idea and to present your digital prototype. Some online forums offer full protection of intellectual property so that no one steals your idea, while others may not. Before you join and submit anything, take time to read the FAQ along with the Terms and Conditions of the online platform you’re planning to use. If you can’t find anything that suggests intellectual property protections, stay away from it. Of course, the safest way is to bring your idea to professional prototype developers or to market it to manufacturers. Always have a valid non-disclosure agreement before you show them the product proposal.

No one says that transforming an idea into a new product prototype is going to be an easy process. Due diligence concerning patent rights and market research is necessary in addition to developing the idea itself into a fully working model. Nevertheless, it’s possible to do even by everyday inventors. You may be able to create a prototype on your own or with the help of a skillful handyman, but if not, there are plenty of custom manufacturers and prototype developers all around the world to help you materialize any concept you have.

Need help with a prototype for your new product design? Learn how Cad Crowd can confidentially connect you with vetted CAD designers and engineers on demand.