Global rank:

11,961

/

122,022

Skill pts: 5

About

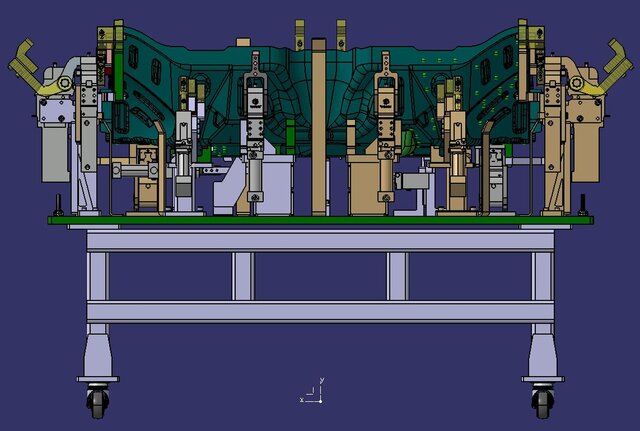

I am a Mechanical Design Engineer with 3 years of experience in Automotive Body-in-White (BIW) fixture and SPM tool design. I have worked on global OEM projects including Ford, Tesla, BMW, Mercedes, Volvo, and JLR, delivering production-ready tooling solutions with high accuracy and on-time delivery.

My expertise includes concept design, 3D modeling, 3D finishing, and manufacturing-ready 2D drawings using CATIA V5, FIDES, NX, Solid Edge, and SolidWorks. I have strong hands-on experience in welding fixtures, grippers, conveyors, screwing fixtures, and assembly tooling, along with solid knowledge of GD&T, tolerance stack-up, NAAMS/DIN standards, and DFM/DFA principles.

I am skilled in interpreting process plans, spot weld plans, clamping and locating strategies, and preparing complete engineering documentation such as BOMs, buy-off sheets, ergo sheets, sequence sheets, and clamp validation reports. I am detail-oriented, adaptable, and comfortable working remotely with international clients to deliver efficient, manufacturable, and cost-effective design solutions.

... more »

« less

My expertise includes concept design, 3D modeling, 3D finishing, and manufacturing-ready 2D drawings using CATIA V5, FIDES, NX, Solid Edge, and SolidWorks. I have strong hands-on experience in welding fixtures, grippers, conveyors, screwing fixtures, and assembly tooling, along with solid knowledge of GD&T, tolerance stack-up, NAAMS/DIN standards, and DFM/DFA principles.

I am skilled in interpreting process plans, spot weld plans, clamping and locating strategies, and preparing complete engineering documentation such as BOMs, buy-off sheets, ergo sheets, sequence sheets, and clamp validation reports. I am detail-oriented, adaptable, and comfortable working remotely with international clients to deliver efficient, manufacturable, and cost-effective design solutions.

Service offers

Experience

-

Junior Design Engineer

Moldtek technologies pvt Ltd · Full-time

May 2023 –

Jan 2026

2 yrs 8 mos

Hyderabad, TS, India

I have designed and developed Automotive Body-in-White (BIW) fixtures and grippers for body sides, closures, underbody, wheelhouse, side window glass, and battery tray assemblies using CATIA V5, FIDES, NX, Solid Edge, and SolidWorks. My role involved creating concept designs, 3D finished models, and manufacturing-ready 2D drawings in accordance with OEM standards and tooling guidelines.

I regularly analyzed and interpreted process plans, spot weld plans, clamping and locating strategies, tool interactions, and fixture layouts to ensure manufacturability, accuracy, and functional performance. In addition to design activities, I prepared complete engineering documentation such as bills of materials (BOMs), buy-off sheets, ergo sheets, sequence sheets, kit sheets, and clamp validation reports.

I successfully delivered more than 100+ BIW fixtures, grippers, and conveyors for Ford projects using the FIDES tool, meeting quality requirements and project timelines. I also created over 200+ OEM-standard 2D drawings, which helped reduce design rework by approximately 15% through precise detailing and strict adherence to standards. Throughout my work, I collaborated closely with cross-functional teams to ensure design quality, compliance, and on-time delivery of project milestones.

Education

- Sri vasavi engineering Colleges Tadepalligudem B.Tech, MECHANIAL ENGINEERING, 8.34 2020 – 2023

Other experience

-

Junior design engineer-SPM

During my deputation as a Junior Design Engineer – SPM at Wipro PARI from June 2025 to September 2025, I worked on the BIW assembly conveyor line following PARI standards. I was responsible for designing and checking SPM tools, ensuring accuracy, manufacturability, and compliance with project requirements.

I contributed to the Ford FHEV Battery Pack Line projects (P24CQ and P24U1), where I handled 3D modeling, design checking, and detailed 2D drawings. Through optimized material selection and improved design methods, I helped achieve approximately 15% cost reduction. I also developed ducting concepts, ensuring correct clearances for all commodities across stations within assembly constraints.

In addition, I created station layouts, cable length calculations, DAP documents, and overall plant layouts using AutoCAD. I managed ExDM data uploads, handled server submissions, and resolved upload errors to ensure accurate, compliant, and timely data delivery to the PLM system. Throughout the deputation, I collaborated with cross-functional teams to support smooth project execution and on-time delivery.

Licenses & Certifications

- GD&T and Stack-Up Expert Dec 2025 – Present See credential