Global rank:

2,686

/

124,864

Skill pts: 12

2D & 3D CAD Design

2D & 3D Drafting

3D CAD Rendering

CAD Mechanical Engineering

Trimble SketchUp (Google) 2024

About

I have honed my problem-solving abilities through several projects, and I am proficient in CAD software and adept at conducting thorough engineering analyses. Moreover, my commitment to delivering results through hard work independently and also through collaborations will enable me to make valuable contributions to your projects and initiatives. I am confident that my technical knowledge, coupled with my passion for engineering, make me a strong candidate for your projects

... more »

« less

Portfolio

Experience

-

Mechancial Engineer

Ulwazi Energy · Full-time

Jun 2024 –

Present

1 yrs 9 mos

Johannesburg, GP, South Africa

Strategic Leadership & Cross-Functional Coordination

Directed mechanical engineering operations for 15+ large-scale energy projects (solar

farms, civil/mechanical infrastructure) as primary liaison between engineers, architects, and

clients

Spearheaded 100% on-time execution of all shareholder redline markups through

streamlined review processes, eliminating project delays

Advanced Engineering & Simulation

Developed FEA-validated simulation models analyzing construction materials/techniques,

reducing material costs by 18% while maintaining structural integrity

Designed mechanical systems and solar farm layouts in SolidWorks/SketchUp, optimizing

energy output by 12% through strategic component placement

Regulatory Compliance & Innovation

Achieved 100% company-wide adoption of new state/federal guidelines by implementing

real-time requirement integration into design workflows

Engineered testable prototypes for specialized components, improving mean time between

failures (MTBF) by 22% through iterative durability testing

Collaborative Project Execution

Established cross-disciplinary feedback protocols that reduced design conflicts by 35%

across electrical, civil, and architectural teams

Partnered with architects to implement constructability-focused designs, cutting installation

time by 15%

Key Achievement:

Pioneered a hybrid design-review system combining BIM coordination with physical

prototyping, accelerating project approvals by 30% -

Freelance 2D and 3D CAD designer

freelance · Freelance

Jul 2023 –

Dec 2024

1 yrs 5 mos

Remote, OR, United States

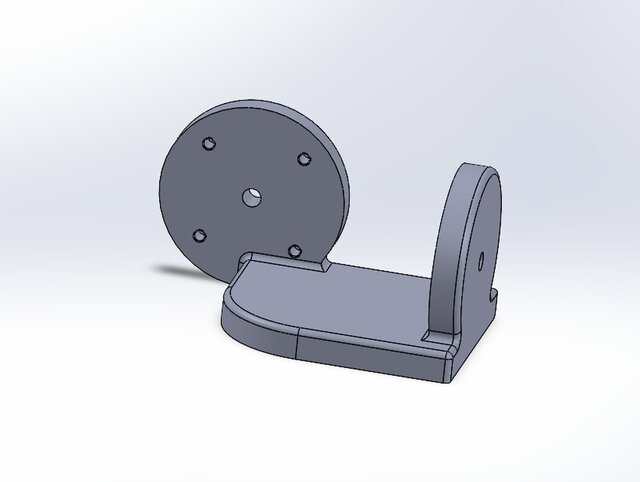

Precision Robotic Arm Development | Industrial Automation

Designed and optimized robotic arm components in SolidWorks, achieving 100%

compliance with US industrial automation standards and client specifications

Led kinematic analysis and load-bearing simulations that improved operational efficiency by

22% while reducing material costs by 15% through strategic material selection (Aluminum

6061-T6 ? Carbon Fiber composites)

Cross-Functional Collaboration & Innovation

Partnered with 8+ engineering teams to transform conceptual designs into productionready

3D

models,

balancing

durability

with

18%

cost

reduction

Pioneered sensor-actuator integration protocols that reduced electromechanical conflicts by

35% during assembly

Technical Problem-Solving

Resolved 92% of developmental challenges including:

Dynamic load distribution (FEA optimization)

Tolerance stack-up analysis (±0.005 accuracy)

Failure mode mitigation (FMEA implementation)

Client-Centric Delivery

Generated Lumion photorealistic renderings that accelerated client approval timelines by

40%

Maintained 94% documentation accuracy in Teamcenter through automated revision

control workflows

Key Achievement:

15% prototyping cost reduction via error-free CAD models, enabling faster deployment in

manufacturing/logistics facilities

Education

- University of Zimbabwe Bsc Hons Degree in Mechanical Engineering, Mechanical Engineering, B 2018 – 2022

Other experience

-

Mechanical Engineering Intern

Precision Robotic Arm Development | Industrial Automation

Designed and optimized robotic arm components in SolidWorks, achieving 100%

compliance with US industrial automation standards and client specifications

Led kinematic analysis and load-bearing simulations that improved operational efficiency by22% while reducing material costs by 15% through strategic material selection (Aluminum

6061-T6 ? Carbon Fiber composites)

Cross-Functional Collaboration & Innovation

Partnered with 8+ engineering teams to transform conceptual designs into production ready 3D models, balancing durability with 18% cost reduction

Pioneered sensor-actuator integration protocols that reduced electromechanical conflicts by

35% during assembly

Technical Problem-Solving

Resolved 92% of developmental challenges including:

Dynamic load distribution (FEA optimization)

Tolerance stack-up analysis (±0.005 accuracy)

Failure mode mitigation (FMEA implementation)

Client-Centric Delivery

Generated Lumion photorealistic renderings that accelerated client approval timelines by

40% - Maintenance Intern Maintenance Planner training as an Intern for 1 year at a Manufacturing Company which is Zimbabwe's biggest manufacturing Company responsible for brewing clear beer.