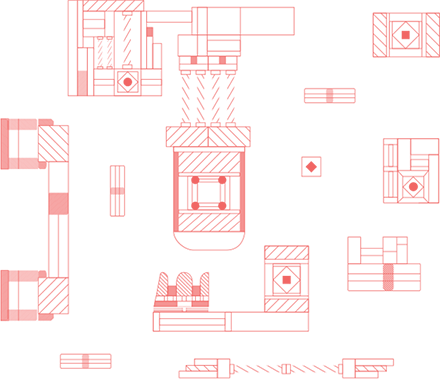

Congratulations! You have a product idea that is innovative and will resonate with your target audience. Now it’s time to design the product and ensure its future assembly. However, before you begin to go any further into the design process, it’s crucial to understand the importance of the design for assembly (DFA) process.

At its core, the DFA process allows you to plan for an optimal method for producing the parts associated with building your product. It takes into account cost, efficiency, and optimal manufacturing. DFA is crucial to ensuring your product is ready for production and can even make the decision of whether to use automatic assembly an easy one to make.

The first step in realizing the savings and efficiency benefits of DFA services is to hire a talented freelance CAD designer to walk you through this process. As an entrepreneur or business owner, your design goals must line up with your business objectives. For a decade, our team has worked with professionals like you to ensure this happens. This reason is why we developed the Cad Crowd design freelancer platform.

Our platform makes the process of finding a designer to handle the DFA process straightforward and manageable. So, for more insight into how this process can help your business, and how our team can help you walk through it, keep reading below.

The goal of every person who creates a product is for this item to generate revenue. For this to happen, the product has to be repeatedly sold. At some point, it will likely even be mass-produced. DFA services can ensure that the assembly for this product is cost-effective and easy to replicate.

However, entrepreneurs need to let go of a prototyping mindset. This step allows them to take into account all the costs and processes associated with mass production. Here are some ways DFA can benefit your company and why it is necessary for your production processes:

Requires you to consider your specifications – Are your specifications realistic? Can they reliably be replicated, even if someone you don’t know is in charge of assembly? You want to make sure that your product’s measurements are created with mass production in mind. DFA allows you to go through the thought behind your specifications and alter them in a way that is more favorable for your assembly process.

Choosing the right materials – Much like the specifications, DFA also requires you to take a closer look at your materials. Do they adequately complement the specifications, and are they cost-effective in production? Again, you need to design your product in a way that accounts for the assembly process, and considering the materials involved is a large part of that process.

Decrease your production costs – Can you decrease the number of parts needed? Are their special tooling or systems required for parts of your product? Working with a product design service who specializes in DFA will help you walk through these questions and re-evaluate the design of your product to make more cost-effective production and material selections.

Reduce labor and time – Reducing the number of parts as well as using materials that are easy for assembly also reduces the labor and time needed for construction. As you decrease these two factors, you will reduce your production and overall costs associated with the product. Again, you are looking for efficiency, and one of the best ways to do it is to design your product with assembly in mind.

Reduce “opportunities to fail” – When you take the time to think about the entirety of the design process, then you are also thinking of strategies that prevent failure. Reducing the number of parts used in the assembly, as well as diminishing labor and time, can lessen the likelihood of costly errors that push your project back.

Produce a better product – When efficiency, innovation, and strategic thinking align, you always create a better atmosphere for producing a more high-quality product. All the benefits mentioned before can reduce mistakes, improve the time it takes to complete the assembly, and make it more likely that you will pick materials that are better for the manufacturing process. All of these increase the chances that you will produce a product that is better for your target audience.

These are some of the primary benefits associated with the DFA services process. However, before you can realize them, you need to work with a designer who specializes in this field. Our platform makes finding a DFA services designer straightforward. You no longer have to spend weeks combing through resumes or setting up what feels like endless interviews.

For more insight into how we help you find excellent design talent, please take a look at our How It Works page. Whether you want to choose from a variety of designs, or quickly purchase a block of time with onehttps://www.cadcrowd.com/manufacturing-services/injection-molding-casting designer, our platform can ensure you find the best.

We have gone through some of the benefits of this process, but it is worth it to also talk about why companies must engage in it. Ultimately, DFA requires you and the designer you choose to walk through assembly best practices. It helps you to acknowledge that one day, your sleek new product will be put together by a 3D modeling designer or robotic hands. The last thing you want is for an excellent product that can meet the needs of your customers to get caught up in assembly because the design isn’t conducive to production.

DFA enables you to get out of your bubble and think about those who will be interacting with your product. Before it reaches the hands of your customers, your product will first be handled by a machine or a person. You want to give them every opportunity possible to build your product to be durable and ready-for-use.

When you neglect the DFA process, you are leaving assembly up to chance, which can be a costly mistake. Fortunately, our team is ready to help you find a designer who is more than capable of producing products that take the assembly and tooling process into account.

While we do offer general DFA services, we also provide offerings that complement this service. Please take a look at how else our team at Cad Crowd can help you.

Product design – In addition to DFA, our team can help you with the entirety of the product design process. We will adhere to the scope, budget, and timeline specifications to help you design a product that resonates with your customers. Whether you are still in the concept phase or are ready for production, our team is prepared to assist in the product design process.

Prototype tooling and manufacturing – We work with some of the most skilled manufacturing and tooling partners in the country. Whether you are looking for longer-term production, or a short production run, our partners can help you develop a prototype that will help you make further decisions about the manufacturing process.

Injection molding and casting – Do you already have a prototype? Are you ready to take your product into production? Our injection molding and casting services can get you ready for the manufacturing process. Whether you are designing a product that uses plastics or metal alloy, our team can help you connect with manufacturers who are ready to take you to the next stage in your production timeline.

3D printing – For the past decade, 3D printing has grown in popularity due to its cost-effective and accurate manufacturing processes. We can help you receive Polyjet, Z-Corp, or Fused Deposition Modeling, and our team can also help design your product for 3D printing production.

Direct digital manufacturing – Did you know you can produce parts and assemblies from a digital CAD file? You can bypass the limitations of traditional manufacturing to develop functional parts from CAD files in much less time. Our team at Cad Crowd specializes in facilitating efficiency and cost-effective systems, and DDM is one of the ways we offer this.

These are just some of the services we offer that can complement your DFA project. For a look at more of our offerings, we invite you to visit our Services page.

DFA is a cost-savings and efficiency tool. It not only makes the manufacturing process more manageable, but it also allows you to produce a more quality product.

DFA can be a technical and intricate process, which is why we encourage you to find a designer with experience in this process. Fortunately, you do not have to look far. Our global network of designers includes those who have a talent for designing products with assembly in mind.

Whether you are at the start of the process or have begun to take a closer look at materials and systems, our designers can help. If you are ready to get started, we invite you to reach out to us for a free quote today!

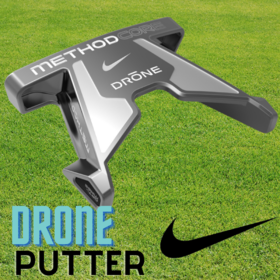

At Cad Crowd, we have the privilege of working with many product designers. Our network of professionals has assisted some prestigious clients including Tupperware and PepsiCo. If you'd like to get similar help, contact us today