This post covers key differences between prototyping and prototype engineering for companies and firms. According to the Merriam-Webster Dictionary, a prototype refers to a product’s first full-scale and “usually” functional model. The Oxford Advanced Learner’s Dictionary explains that a prototype is the first design based on which other forms are developed. Both are correct, but the combination makes for a more accurate definition. A prototype is the first iteration of a design used as the foundation to build a more refined version. There are several different builds of prototypes, from simple sketches on paper to a true-functional model nearly identical to the final product intended for mass production.

A functional prototype closely resembles the intended design and works as a subject for various testing procedures to generate feedback on features, form factors, and performance. No matter how well the test results are, a functional prototype is not the final version of a product. Design engineers and designers may still need to refine the design to address any issues discovered during the test period.

RELATED: 6 Ways you can use 3D printing services to create a new prototype design

Prototyping

A rough pencil sketch on paper is an early form of a prototype. When you come up with an idea for a new product, the quickest and easiest method to make a record of the concept is a hand-drawn visualization. As the development continues, the sketches receive recurrent improvements and transform into detailed (and more technical) product images. There can be multiple two-dimensional visualizations to represent different versions.

Supplemented with market research and engineering input from professionals, you will eventually arrive at a point where one specific design iteration (out of many possibilities) comes out as technically viable and financially sensible. Much of the product development workflow revolves around prototyping, which can be defined as an experimental approach to creating a feasible design configuration. It is the phase where you study, build, test, and alter the design as needed. Rapid prototyping services involve an iterative process, an integral part of the design analysis and development cycle. It has two main goals:

RELATED: Different kinds of prototypes and how to use them for your design project

- Visualization: having a representative model—physical or virtual prototype—of a product makes it easier to explain a concept. At the same time, the audience can always refer to the model for additional insights into your idea.

- Evaluation: Prototyping facilitates the analysis to check for design flaws and ease of use. It helps identify room for improvement, which subsequently determines design direction. In addition to the development team, the target consumers should be allowed to evaluate the product design.

Another important objective is safety. A prototype design engineering firm ensures there is nothing wrong with the product, and users can benefit from it without worrying about unwanted health risks or side effects. After a series of tests and reviews, you can figure out how to write comprehensive safety instructions for the end product when it reaches the market.

RELATED: How to design the best prototype for your new product

Prototyping encompasses both theoretical and experimental practices to develop a product. Ideas and concepts are theoretical; they are tested, not on paper, but in a real-world scenario where end users have first-hand experience with an experimental version of the product. The process includes a series of design analyses and market research, of which the resulting data are put together as a pragmatic guide to innovation or improvement. Prototyping represents almost the entirety of a product development process, with the sole exceptions of initial brainstorming and mass manufacturing phases.

Prototype engineering

A distinction has to be made between prototyping and prototype engineering. Prototyping signifies an extensive process that may involve studies of consumers’ preferences and competitors’ performance to solve the product design puzzle. On the other hand, prototype engineering is a stand-alone task that focuses on fabricating a prototype. Prototype engineering is mainly about the technical feasibility of a design.

Mass manufacturing services forms part of the next step in product development after finalizing the design. It makes little sense to build a prototype only for it to be unjustifiably too expensive to mass produce. There can be two reasons for the issue: the design is too intricate that it unnecessarily increases manufacturing complexity, and some parts or assemblies require custom/specialty tooling yet to be made.

RELATED: How to hire a product design engineer: top 3 considerations for your business

Every prototype has to be engineered to fulfill its purpose:

- A proof-of-concept model requires little engineering input as it only showcases form-factor and dimensions.

- A looks-like prototype must display a refined version of the product’s aesthetic aspect.

- A works-like prototype is a functional model.

- A final prototype is where looks-like and works-like merge into a single model, resembling the final product.

Prototype engineering ensures every single model is built efficiently per its design requirements and purpose. For example, there is little to be gained from heavy investments (money and time) in making a proof-of-concept. A simple mock-up made of cardboard and foam should suffice if the intention is to illustrate the basic shape of a product. In contrast, building a final prototype takes serious effort and a sizable budget.

RELATED: What is engineering for manufacturing (EFM) for new products at a prototype design services firm?

Not only does a final prototype demonstrate functionality and aesthetic appeals, but it also validates the product’s manufacturability factor, such as:

- Parts and assemblies are made of easily-sourced materials

- All components are shaped using readily-available fabrication equipment

- Everything is put together in a practical configuration for manufacturing efficiency

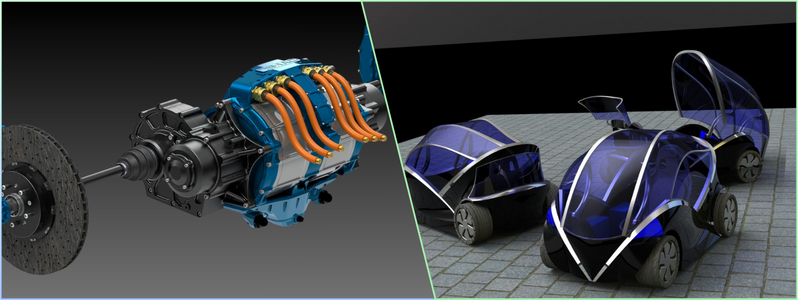

CAD drafting and design firms perform many prototype engineering tasks on computers using CAD software. A 3D digital mock-up helps create a perfect geometry and proper assembly. However, the task is not over until the virtual model becomes a physical object. Although everything may look flawless on a screen, there might be some challenges during the fabrication phase.

The most significant advantage of 3D CAD software is that all parts and components are modifiable, seemingly without restrictions. Prototype engineering helps establish design parameters and constraints to avoid drawing/creating non-manufacturable objects. Indeed, rapid prototyping (with either CNC machining services or 3D printing) will tolerate even the most intricate design, but such a method is not for mass-production purposes. Die-casting, injection molding, or a combination of the two remain the most cost-efficient options for high-volume production.

RELATED: Top 9 design engineering tips for reducing manufacturing costs on new product designs & prototypes

In a nutshell, prototype engineering refers to all activities required to engineer a final prototype to represent a final product ready for mass manufacturing. The focus is fabricating a sample/model to improve the chances of the prototype adhering to the factory partner’s manufacturing capability. Some of the most critical tasks within the scope of prototype engineering are as follows:

Specification definition

Every engineering work always produces a specification sheet. Unlike sketching or brainstorming, specifications are the reference points for all activities. In a prototype engineering work, the references should “at least” mention the following:

- Design parameters and constraints

- Permissible dimension deviation (tolerance)

- Safety requirements

- Types of deliverables (documents and designs)

- Fabrication methods for the prototype

- Expected mass-production method

There needs to be testing schedules and procedures, too. A part or assembly’s specific features, characteristics, and performance values must be validated before moving to subsequent engineering activity.

RELATED: What are reverse engineering costs, consulting rates & design pricing for companies?

Reverse engineering

In case the market has already offered similar products from competitors, there is nothing wrong with reverse engineering. An in-depth knowledge of how a comparable product works open the door to creativity and innovation. The point is not to copy other designs but to discover any possible shortcomings and create an improvement. Even if the reverse-engineered product has no flaws in the internal mechanism and functionality, sometimes it still has room for improvement in other aspects, such as ease of use and repairability.

Virtual prototype using 3D CAD

With 3D CAD software and simulation tools, you can build an accurate digital product mock-up. The mock-up is more than just a glorified sketch but a full-scale virtual prototype that shows how the product looks and functions. It is also possible to digitally disassemble—and reassemble—the object on screen to see the internal mechanism, including individual assemblies and parts. If the product is meant to complement others, for example, HVAC components or machinery accessories, simulation software demonstrates how they fit.

RELATED: 10 Tips on how to find the best prototype engineering firm services

Build it

Virtual prototyping is an advanced tool that enables engineers and designers to draw exact designs. Depending on the file format, it works with 3D printing and CNC machining for rapid fabrication. As mentioned earlier, rapid prototyping is not mass manufacturing. The engineering team must consider the final product’s materials and tooling regardless of the prototyping method. Depending on the type of product and its intended use, engineers have to consider material properties such as heat resistance, conductivity, structural rigidity, durability, weight, and density, among others. At the end of the day, the production budget and time always constrain the selection of materials and mass-production methods.

Prototype engineering is a task within the “prototyping” phase of product development. The task involves figuring out the most budget-appropriate method to build various prototypes following the development progress, including types of materials and fabrication methods. The final prototype should be only marginally different from the final product in terms of design, manufacturability, and production cost.

RELATED: 3D Printing technologies for modeling and prototyping

How Cad Crowd can help

Working with the best engineering firm or prototype company is critical for transforming ideas into fully functional products. It is important for inventors to choose a company with reasonable service costs, vast experience, and policies for the protection of the inventor’s intellectual property rights. The prototype company or engineering firm must also have the experts and technology required to finish the project right on time. Don’t let your hard work go to waste. Always work with the best in the field.

Don’t forget to patent your invention! Use Cad Crowd’s On-Demand Patent Attorney Search to get all the help you need navigating the patent process. If you’re looking for expert CAD designers make use of our CAD design service to connect with the best CAD designers and drafters in the United States and bring your ideas to life. Receive a free quote.