You’re a design lead at a hectic product design company. You’ve just landed a new client with an excellent but challenging product idea, maybe a new consumer product that’s sexy and thin, an ergonomic piece of furniture with an unexpected twist, or a kitchen appliance that’s smart and will revolutionize how people prepare meals each day. Everybody’s elated, but deep down, you know that the road ahead is fraught with perils. Will the product do what it’s supposed to do? Will production glitches sidetrack schedules? What if the market doesn’t bite?

Cutting risk in new product development (NPD) isn’t so much a checklist or a tidy process flow; it’s an art and a science wrapped up. In this in-depth piece, we’ll take you through the way design services firms at the industry leader Cad Crowd can effectively identify, handle, and reduce the types of risks that can make an innovative product vision a pricey disaster. We’ll bypass the generic software-only suggestions and jump into the nitty-gritty of products and physical goods you can touch, try, and send.

🚀 Table of contents

- Understanding the nature of product development risks

- Begin with definitive, realistic product requirements.

- Invest in rapid prototyping, fail fast, learn fast.

- Select materials and processes carefully.

- Manage the supply chain and vendor relationships proactively

- Use modular and flexible design methods.

- Leverage sustained testing and validation beyond the basics

- Create a cross-functional development team.

- Plan for regulatory and compliance issues up front.

- Organize realistic timelines and budgets with buffer.

- Apply risk assessment and management tools as a matter of course.

- Create a culture that welcomes risk awareness and learning.

- Bringing it all together: A product development story

- Last thoughts: Risk is inevitable, but manageable

- Ready to minimize your product development risks?

Understanding the nature of product development risks

Let’s chat about the sneaky risks that hide in product development. Before jumping into how to dodge them, it’s smart to know what kinds of risks you’re actually dealing with. Usually, these risks fall into a few buckets: design, manufacturing, market, and operational. Each one can throw a wrench in the works if you’re not careful.

Take design risks, for example. For companies that specialize in design services, the real challenge is striking a balance between creative ideas and practical limits. It’s not just about dreaming up something cool; you’ve got to juggle things like technical feasibility, budgets, deadlines, quality standards, and what customers really want.

Imagine you’re creating a new smart coffee maker. The other decisions you make upfront are enormous. They set the direction of everything that comes next. The materials you select will determine the source and longevity costs. The manufacturing for assembly design services ensures that you can source quantities easily and build upon them quickly. The user interface? That can be customer-centric or customer-kamakai. Risks creep in when assumptions about any of them get forgotten, aren’t rigorously tested, or when the team is out of sync.

So, here’s the magic to managing it all. The trick is identifying those risks early and catching them frequently by interweaving intelligent risk-management techniques throughout the entire project lifecycle. That way, you never see surprises and maintain a smooth-running product development train.

Begin with definitive, realistic product requirements.

Let’s talk about why starting with clear, realistic product requirements is absolutely crucial for any successful design project. You’ve probably heard the phrase “garbage in, garbage out,” and it couldn’t be more true here. If the product requirements are vague or too optimistic, it’s like trying to build a house on shaky ground; it can lead to confusion, wasted effort, and risk.

Consider the case of a client who requests a chair that is “lightweight but very resilient,” but doesn’t define what “lightweight” or “resilient” specifically entails. Without targets, designers may pursue unattainable trade-offs, going round in circles without ever arriving at a viable answer.

That’s why world-class design services firms spend time up front in a careful, collaborative requirements-gathering process. They take the time to sit down with the customer to pin down precisely what the product needs to accomplish, who will be using it, where they’ll be using it, and what regulations need to be adhered to. They also keep things real; if some of the requirements run counter to budget or timelines, they’re realistic about that.

One intelligent instrument is a “requirements matrix”, an easy-to-read chart that converts client desires into quantifiable objectives, such as max weight in pounds, minimum load capacity, or operating temperature ranges. This specificity provides designerswith firm guardrails, reduces guessing, and substantially lowers the cost of costly last-minute redesigns. Clear requirements = smoother design, happier clients, and superior products from product design experts.

RELATED: How to reduce costs on 3D product development with remote CAD experts for companies

Invest in rapid prototyping, fail fast, learn fast.

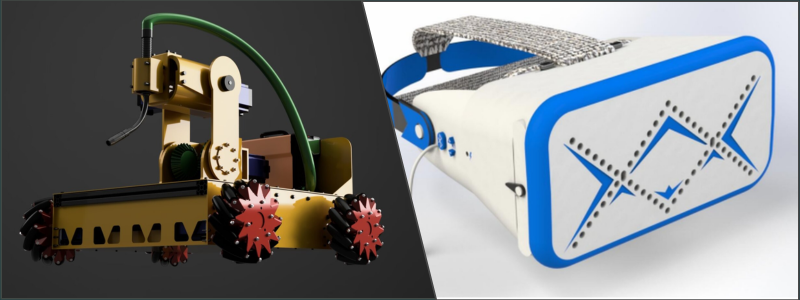

Investing in rapid prototyping is one of the best things a product development team can do. Rather than relying on elaborate CAD drawings and praying that manufacturing will get it all right, rapid prototyping turns ideas into actual models in a hurry and at low cost. Working this way catches mistakes in the design early on before they become costly headaches.

By making several versions of prototypes, ranging from rough 3D-printed components to working models, teams find issues that could otherwise remain concealed until production or even after the product has been released. For instance, perhaps a button is uncomfortable or a plastic piece breaks when exposed to heat. These failures aren’t failures; they’re time- and cost-saving lessons learned.

Real-world user testing is now also an option with prototypes. Users tend to have surprising preferences or usability bugs that allow designers to iron out the product prior to setting final materials or tooling. A few companies even accelerate the process further by mixing in-house prototyping with simulation software, enabling them to cycle through their ideas quickly without burning resources.

Ultimately, embracing rapid prototyping design services means learning fast by failing fast. Early testing leads to fewer surprises, smoother manufacturing, and a better product in the hands of customers. It’s a proactive way to reduce risk, improve design, and boost the chances of success.

Select materials and processes carefully.

Selecting the correct materials and manufacturing processes is more than a technical specification issue; it’s a process that can avoid wasteful missteps down the road. The incorrect material will create product failure, unseen expenses, or frustrating delays in the delivery of parts. Similarly, the manufacturing process will establish the project’s success or failure in the areas of quality and productivity.

Take exotic composites, for example. They might be incredibly strong and durable, but perhaps at the expense of higher costs and supply chain interruptions. Injection molding, on the other hand, might be wonderful for producing a lot of parts economically, but it requires costly tooling upfront as well as more setup time before running.

Design services companies overcome these obstacles by striking a balance between new-fangled creativity and time-honored practices. They negotiate varying materials and methodologies up front, weighing factors like cost, availability, environmental factors, and the quality of the vendors. Seizing control early on avoids surprises later on.

Close collaboration with the manufacturing design services at the design stage is another significant strategy. They ensure jointly that the product can actually be produced within their budget and time frame, without cutting corners on quality. This common exercise combines design ideas with what is possible by way of manufacturing, minimizing risk, and keeping the project on schedule.

Manage the supply chain and vendor relationships proactively

Proactively managing the supply chain and vendor relationships is a game-changer for any product. The best, most flawless design can fail if the supply chain is not strong. Sourcing material delays, surprise quality problems, or abrupt price variances can upset schedules and destroy customer confidence.

Design firms have to have vendor management in mind as a key part of risk management. It starts with thoroughly qualifying suppliers to ensure that they are satisfactory and meet expectations. Having some redundancy in having multiple suppliers in the pipeline provides a cushion when things fail. Monitoring supplier performance closely on a regular basis, nipping things in the bud before they become major obstacles, is a must.

Having standby contingency plans for disruptions is also extremely important. Unforeseen issues like geopolitical instability or raw material scarcity can’t always be expected, but maintaining alternate vendors or substitute materials on standby keeps the project moving.

The best teams don’t think of vendors as order takers. They develop strong relationships, built on cooperation and trust. Inviting vendors into the design phase earlier creates those types of gems that improve the product and reduce the cost. This strategy makes supply chain management a profit driver that enables successful product launches and long-term success, which also includes engineering design partners.

Use modular and flexible design methods.

The use of modular and flexible design techniques can truly transform the manner in which products are designed and serviced. Breaking down a product into discrete, stand-alone elements, termed modular design, gives the advantage wherein each piece can be individually designed, tested, and updated. This approach will lower the possibility of total failure by compartmentalizing faults, making it easier to debug.

Think of a smart speaker with separate modules for sound, power, and casing. If the sound module goes awry, it can be repaired or replaced without rejecting the entire device. Not only does this minimize cost, but it also simplifies making the product for different customer needs or markets. Enhancements and upgrades are less daunting as improvements can be focused on individual modules instead of overhauling the entire product.

Flexibility is a companion to this, preparing for changes in production. Instead of calling for impossible precision, flexible design includes small tolerances in parts or steps. This flexibility from open innovation services is especially its weight in gold when it is time to go from the prototype stage to mass production, dodging quality control issues that usually bring trouble.

Together, modularity and flexibility make product development more robust, cost-effective, and scalable. Companies can respond faster to shifting markets, handle risk more effectively, and keep customers longer with products that change automatically over time.

Leverage sustained testing and validation beyond the basics

Product testing isn’t just to check that it functions; it’s to push it to the limit and then some. Validating correctly is more than that, pushing endurance, safety, and performance in tough environments, and making sure to check all regulatory boxes. The goal is to find vulnerabilities before the product even makes it to customers.

Preeminent product engineering design services companies know this. They do not rely on one test but take on multiple stages of rigorous testing. From bench testing, in which separate components are checked, to environmental simulations that replicate extreme temperatures of heat, humidity, or vibration, they move on. Then come real-world applications that mimic the very types of issues customers encounter on a daily basis. Topping it all off is certification preparation to ensure that the product meets industry and government standards. It even involves destructive testing at times, knowingly driving parts to failure until they fail. It may sound extreme, but this does reveal failure modes that otherwise may not be evident, yielding extremely valuable information. These are the kinds of findings that result in incremental but meaningful design changes, greatly enhancing reliability and boosting customer confidence.

The rewards of this strict approach extend well beyond product quality. By firmly testing designs at the outset, firms escape costly headaches such as recalls, lawsuits, and battered reputations. In the end, it’s a good investment that pays off in terms of long-term achievement and a clear conscience.

Create a cross-functional development team.

Creating a truly superior product is more than a single expert doing it alone. Design services companies creating cross-functional development teams set themselves up for success because they bring several skill sets into the game from the very start. When industrial designers, mechanical engineers, manufacturing specialists, supply chain managers, marketers, and quality assurance professionals are all contributing together, the process of creating the product is significantly stronger and better.

Each team member has a unique perspective that, in turn, affects the product significantly. Manufacturing engineers can identify expected manufacturing issues that can complicate large-scale production, whereas marketers offer loads of information about expected user tendencies and emerging market trends. Quality assurance experts keep everyone reminded of significant regulatory and safety implications that the product must comply with.

This blend of abilities generates initial discovery of risks that would otherwise be a killer for the project if they are later discovered. It further helps avoid letting the product vision deviate from realities in the real world, balancing creativity and feasibility. Transparency and open communication are paramount, and jointly used digital tools have become indispensable. Such tools promote seamless sharing of ideas and progress, avoiding misunderstandings and costly blunders.

A cross-functional team is not a nicety, but a strategic idea that allows companies to deliver new, functional, and sellable products earlier with greater assurance.

RELATED: Top 3D PCB design software your service provider needs for electronics design

Plan for regulatory and compliance issues up front.

When developing a new product, dealing with regulatory and compliance matters initially can spare much trouble down the line. Too often, teams overlook these critical requirements until they’re deep into the design or development phase, only to run into late-stage surprises that kill the project altogether. Whether it’s achieving the correct safety certifications for electronic device design services, using food-grade materials for kitchen appliances, or ergonomic compliance for furniture, compliance isn’t a checkbox afterthought at the finish. It has an effect on everything from selecting materials to testing methods and even how the product can be marketed.

Future-looking design companies are focused on learning all relevant regulations upfront. In most cases, this includes researching the very specific standards that are relevant and, in some cases, bringing in experts or regulatory consultants to work through complicated rules. This way, teams bake compliance into the actual product, avoiding the costly and time-consuming requirement of redesigns or last-minute fixes.

Aside from preventing delays, compliance planning enhances the credibility of a product. Consumers are assured when they purchase something that they are sure complies with industry standards and safety standards. Such confidence not only guarantees the success of the product but also strengthens the brand as a whole. In short, pre-emptive planning for regulatory hurdles is an excellent decision that leads to more successful launches and satisfied consumers.

Organize realistic timelines and budgets with buffer.

It is important to have realistic schedules and budgets during product development. Among the most frequent mistakes that most teams make is underestimating the time to complete the tasks or the expense. When this happens, deadlines are missed, the budget increases, and quality is compromised because of the rush to catch up. Such a scenario can bring down even the best projects.

Experienced design organizations avoid these traps by creating realistic project schedules that are not based on hope. They include buffer time and extra capital from the start. This includes leaving space for necessary iterations, prototyping phases, reverse engineering services, supplier lead times, and the unavoidable surprise delays. Including these variables in the early stages prevents them from causing chaos down the line.

Keeping the project back on track also depends on reliable milestone reporting and regular review of progress. The milestones serve as an early warning for creeping slippage or cost blowout. By detecting issues early, the team is able to respond to fix them before they spiral out of control.

This systematic project management style rules out surprises and keeps everyone involved, clients, designers, and vendors, on the same page. Finally, it makes sure that the project flows smoothly with the quality product everyone looks forward to without last-minute panic or costly fixes. Pragmatic planning supported by diligent monitoring makes it well worth it.

Apply risk assessment and management tools as a matter of course.

Risk assessment is not a box to check off a list and forget. It is a recurring responsibility that needs to be incorporated into every stage of a project. Successful manufacturing design firms understand this and rely on frequent use of risk assessment and management tools throughout the project life cycle. Official risk matrices, Failure Modes and Effects Analysis (FMEA), and risk registers are favorite turn-to’s.

These tools aren’t just paperwork; they help teams systematically identify potential risks, rank them by their potential impact, and monitor them as the project progresses. By focusing efforts on the most critical risks, teams can prioritize resources and attention where it really matters. Assigning clear ownership for each risk ensures accountability, so nobody is left guessing who’s responsible for mitigation.

Also, having clear records of risks and the actions taken to resolve them builds trust with partners and clients. If risks are documented and being managed, it reflects professionalism and administration. Such transparency can be a major confidence booster, especially in complex projects where issues could easily go wrong.

Short of it, regularly using risk assessment and management tools isn’t really about staying away from problems; it’s about putting into place a systematic process for dealing with uncertainty, aligning everyone, and ultimately producing successful results.

Create a culture that welcomes risk awareness and learning.

An office culture that wholeheartedly welcomes risk awareness and learning is the difference between a business successfully managing problems and one that does not. When companies view risk management as something to be done just to tick a box or as a chore to comply with, they react in panic when unexpected things go wrong, losing time, money, and morale. But companies that build risk awareness into the thinking of the day see risks as warning signs, not bogeymen. It helps them pick up problems early, deal with them logically, and adapt without hindrance.

Encouraging open communication plays a crucial role in this transformation, especially for concept design services. When team members feel safe to voice concerns or flag potential problems without fear of blame or retaliation, risks become visible far sooner. This openness creates a proactive atmosphere where everyone is vigilant, and risks don’t fester in silence.

In addition, a culture of learning from lessons acquired, whether from failure or near misses, makes every difficulty an opportunity to improve. Rather than covering up mistakes, teams examine what failed and learn from them. This learning loop creates resilience and improves the company’s capability not to make the same mistake again.

Finally, it’s about raising risk awareness and learning in order to prevent losses. It’s about creating a resilient, forward-looking organization equipped to succeed in a continuously changing world.

Bringing it all together: A product development story

Let’s place these concepts in a story. Imagine a design firm hired to develop a new line of green kitchen gadgets. Immediately, they collaborate with the client to define specific requirements: durability, compostable packaging, water resistance, and prices. They steer clear of vague terms and establish quantifiable objectives.

They rapidly develop 3D-printed prototypes to test ergonomics and material texture. Initial user testing identifies a grip problem, so they adjust the handle design. Meanwhile, the company consults manufacturing partners and selects a bioplastic that meets cost, strength, and sustainability criteria.

The company maps out potential suppliers and identifies backup sources in case of shortages. The product design is modular, with electronics and mechanics separable, making repairs or upgrades easier. The team runs rigorous tests, including drop tests, moisture exposure, and user safety assessments.

A cross-functional team maintains open communication, flexible schedules, and budgets with buffers. Regulatory specialists make sure the gadgets are FDA-approved and electrically safe. The company relies on risk management tools to monitor risk identification and mitigation progress.

By adopting these measures, the general design firm produces a product that pleases customers, gets to market on time and within budget, while reducing the feared surprises.

RELATED: How is product design different from industrial design services companies?

Last thoughts: Risk is inevitable, but manageable

Risk in new product development is inevitable, but manageable through systematic planning and proactive strategies. Success requires clear requirements, rapid prototyping, smart material selection, strong supply chain management, rigorous testing, and cross-functional collaboration. Companies that treat risk as a manageable reality rather than an enemy create products that launch successfully, on time, and within budget. By implementing comprehensive risk management practices throughout the entire development lifecycle, design firms build client trust and establish reputations for reliability and innovation. The combination of bold creativity with prudent planning transforms potential disasters into market successes.

Ready to minimize your product development risks?

Don’t let unexpected challenges derail your next product launch. Partner with experienced design professionals who understand risk management. Get systematic planning, prototyping, and testing from day one. Cad Crowd is the leading platform for connecting freelance engineering, CAD, and architectural design professionals to AEC companies worldwide. Contact us today for your free consultation and quote.