Nowadays, the barriers for creating new products is quite low. Entrepreneurs and businesses are able to turn new ideas into products through product design. The process of product design is essentially anything that happens up until the product is manufactured and on the shelves.

Designing a new product involves a lot of complex processes and theories – it’s not as simple as just envisaging a product design and putting parts together. In fact, product design involves everything from brainstorming, designing the product aesthetically, determining the best materials to use, its style, and mechanical engineering design.

When trying to come up with a solution to a problem, it’s essential to make sure that it’s functional. This is why CAD is such a useful tool for creating new products. CAD design programs streamline the entire process. They enable collaboration, reduce the need for a physical prototype, along with having many other advantages.

CAD has drastically changed the world of product design. Let’s explore the ins-and-outs of product design and how CAD contributes to the process.

What is Product Design?

As mentioned, product design is either a process or a noun. In this case, we’ll be referring to product design as the process in which you create and design a new product.

There are several stages of turning your new product design idea into a fully-fledged product ready to ship out. Initially, you have to identify a problem that your consumer has which your product may be able to solve. Then, a freelance product designer will determine their goals for their product design and establish how they’re going to work.

Afterward, they brainstorm, often with an entire team, to come up with new product design ideas. At this phase, the ideas can be as wild as you can dream up – even if they’re not possible at the end of the day, you may be able to incorporate some of those wild ideas into the final product.

Designers will select a few of the most promising concepts from a list of ideas and begin to build them up gradually. In the past, designers would be forced to stick them together traditionally. However, nowadays, product designers can do the entire process using CAD.

While some designers prefer to initiate their product design with pencil to paper, the majority operate with CAD. After testing a few of the concepts using CAD and drawing them out, product designers will move onto prototyping. While prototypes nowadays are typically no longer traditional, in that they aren’t prototyped physically, prototyping is still important.

Using CAD, product designers can create their virtual prototypes without spending a penny on physical prototyping. The beauty of CAD is that it’s cost-effective, allows you to iron out the kinks, and lowers the barrier to entry of prototyping. In this step, smaller problems are fixed and prototypes are remade.

Then there’s a final prototyping stage where the aesthetics and function of the product are ironed out. When you know what the final product will look like, and the function is determined, you’re ready to move forward.

History of Product Design

Before CAD

Before the Industrial Revolution, product design as a process didn’t really take place. Most items were created by hand without much planning as to how it would work. Of course, an item could be recreated multiple times by hand, but it was a tedious process and mass-production rarely happened.

However, with the rise of the Industrial Revolution, manufacturers were able to take advantage of mechanization to mass-produce items. Michael Thonet’s No. 14 chair, introduced in 1859, was one of the first items to be mass-produced.

The chair became the standard for cafes and restaurants. This is just one early example of product design during the age, thanks to the creation of the consumer economy and lower prices as a result of mechanization.

RELATED: The Advantages of CAD

In the early to mid-20th century, product designers and consumers themselves began to value form – a product’s aesthetic – in addition to function. It became a necessity for products to be better designed – long gone were the days of an old bucket being sufficient.

Some notable pioneers of this era you should take note of include Henry Dreyfuss, famous for designing everything from household appliances like vacuum cleaners and sewing machines to the interior design of airplanes. Greta von Nessen specialized in lightning, creating the “Anywhere” lamp that took the world by storm.

Although product design rose to prominence, the processes in which industrial designers were operating were time-consuming – that is, they typically worked with paper and pencil. Making changes to drafts and drawings was time-consuming and tedious.

CAD in Its Early Days

Computer-aided design really began to take off in the early 50s and 60s. The program Sketchpad was one of the first pieces of software that, although very primitive, paved the way for the creation of bigger and better CAD programs.

With the invention of the computer mouse and other modern computing necessities, the building blocks were in place for computer-aided design to be used for product design.

Because computers and the like were quite expensive at the time, only large industries like automotive and aerospace engineering were really able to take advantage of CAD software. It enabled them to design many parts more quickly and efficiently than they otherwise would using traditional methods.

However, one interesting thing to note is that there weren’t really any standardized CAD programs being used at the time. Most companies had their own in-house CAD software that was exclusively used by their company.

CAD grew rapidly in the 70s and 80s, until general drafting programs were created. In 1982, AutoCAD was released, which was and still is one of the most successful and innovative CAD software packages available. The lower barrier to entry and reduced cost allowed more and more industries to adopt CAD design.

Product Design with CAD Today

Modern CAD programs are no longer limited to just creating simple 2D drafts or 3D wireframes. The CAD packages of today are fully-equipped with many different features that not only speed up the design process, but also make it more efficient to test designs in real world scenarios.

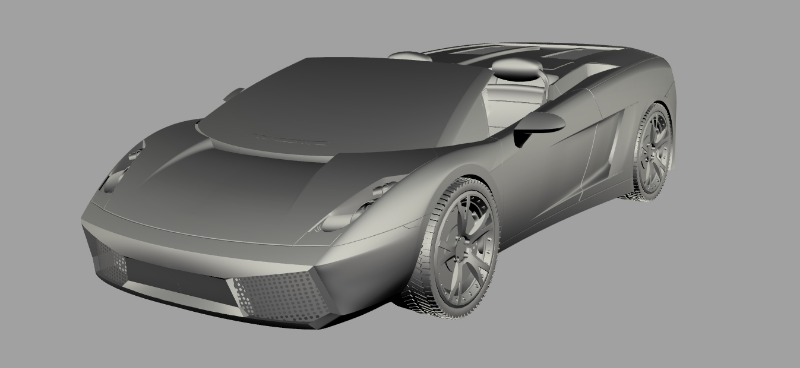

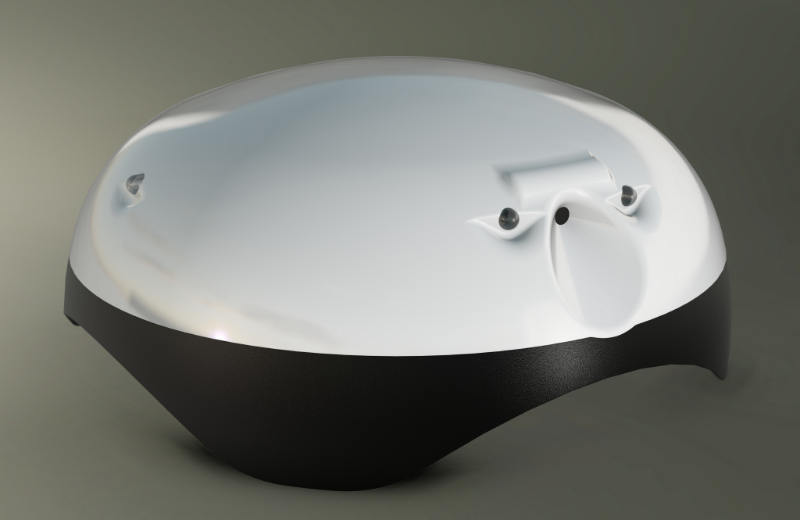

CAD software like SolidWorks and AutoCAD can be used to create 3D models that look exactly how the real product is intended to look. The software can also be used to test a product’s functionalities and reduces the need to create an actual physical prototype. Virtual prototypes are not only more cost efficient, but they’re easier to test against varying scenarios while also changing materials and parts.

CAD has enhanced all aspects of the product design process, allowing designers to work with a degree of accuracy and certainty that would otherwise not have been possible.

Most Widely Used CAD Programs

Because CAD is such a huge enterprise, there are many different types of programs that all cater to different things. Here are some of the most widely used CAD programs.

AutoCAD

As mentioned, AutoCAD was one of the first CAD programs to become widely used by general product designers. And today, it’s still one of the most popular programs.

AutoCAD was released in 1982, and since then, it’s been adapted to mobile and web app use and is widely used across many industries. Architecture, engineering, graphic designers, town planners, and product designers all use AutoCAD regularly.

Freelance AutoCAD design and drafting services have access to verticals for different industries, including AutoCAD Electrical, AutoCAD Mech, and AutoCAD Advance Steel. They are all customized to work best for their appropriate industries. Thanks to AutoCAD’s customizability, it’s adored by many and is really the standard for CAD design.

SolidWorks

Another widely used CAD program, especially in product design, is SolidWorks. The program was created by Dassault Systemes in 1995 and was in use by 165,000 companies as of 2013. Like AutoCAD, SolidWorks creates numerous versions of their program to cater to different groups of customers.

It’s a program that allows users to create 3D solid models. SolidWorks design services praise the program for its ease-of-use, the uncomplicated nature of the program, and how it streamlines the process. SolidWorks allows product designers to create realistic models of their products in great speed and with more ease than otherwise possible.

SolidWorks has created specific iterations for the product design field. SolidWorks Industrial Designer (SWID) and SolidWorks Conceptual Designer (SWCD) support realistic rendering, freehand sketching, and both iterations of this program make the product design process clearer.

CATIA

Created by SolidWorks parent company Dassault Systemes, CATIA is not only a program offering CAD design, but is technically called a 3D Product Lifecycle Management system. Dassault refers to CATIA as a virtual product design suite, while SolidWorks is strictly for 3D modeling and design.

It supports multiple stages of a products lifecycle, providing a place for designers to conceptualize, design, engineer, and even manufacture a product. With its high degree of functionality and convenience, it’s used by many product design businesses to keep track of a product’s lifecycle. With that said, many prefer to initially design the 3D model in something like SolidWorks.

Industries like aerospace and automotive engineering use CATIA at every stage of the product’s design. But for a simpler product design, it can be overkill.

Blender

There are free alternatives to programs like AutoCAD and SolidWorks that are quite effective, including Blender. Blender is a program used often by beginner 3D modelers, although even some professional design firms use Blender for not only graphic design, but to design 3D models for movies and games.

Blender is actually one of the best programs out there for product design, especially for those just dipping their toes into the water. It has a lot of functions that you ’d think would only be reserved for paid programs.

It’s open-source, meaning the users of the program are the ones who are constantly updating it. At times, that means Blender can be more up to date and have features that even SolidWorks and AutoCAD don’t have.

The Advantages of CAD for Product Design

The evolution of CAD has really pushed many industries forward. Automotive and aerospace engineering may have been the first to begin utilizing CAD, but product design may be one of the industries mostly influenced by CAD.

Here we’ll look at some of the concrete advantages of using CAD for product design.

CAD Designs Are More Accurate

When designers were typically drawn up using pencil and paper, they were unequivocally riddled with more errors and mistakes than the designs of today. Even the most accurate drawings can contain inaccurate measurements.

When you’re designing with CAD software, you typically operate using vector images, which contain lines and objects. They’re infinitely more accurate than drawings and raster images, and they offer specific information about the design in question.

Another advantage of drawing with vector images is that it removes the need to draw to scale. You’re simply able to draw your CAD design any which way, and then you can change the scale with the click of a button in CAD software without sacrificing quality or accuracy.

Allows Product Designers to Take Advantage of 3D Modeling Design

When product designers were limited to drawing on paper using a plain old pencil, they were limited to drawing in 2D. While you can try and communicate a 3D design on paper, it’s quite difficult. And as all product designers know, it’s crucial to be able to display a product design in 3D to ensure it fits the criteria of function and aesthetic.

Using CAD software like Blender, product designers are able to create their designs in 3D from start to finish, as well as testing the design in different lightning and material set-ups.

Designing in 3D is advantageous in many ways. You can design your product from the get-go in the way you want it to look in real life. 3D CAD software allows you to visualize the end-product during the whole design process, enabling you to make changes as you go. You can see your product from multiple viewpoints and angles, in different lighting scenarios, and you can even view the interior of a product.

Another benefit of using 3D modeling software is being able to show off what a finished product would look like to clients, investors, and your internal team. It’s easier to sell a product that a layperson can visualize.

Makes Revisions Effortless

With paper and pencil drawings, to make any revisions, you would often have to scrap the entire thing and start again. If it was a small error, an eraser may suffice, but more often than not a 2D draft was thrown out and restarted.

If you want to a create a new version of an already existing product with minor changes, you could either trace over the existing design or draw it from scratch, depending on the changes that need to be made.

With CAD, both of these problems are null and void. If the product designer happens to make a mistake, they can simply use the Undo function to reverse the design to before the mistake was made. Each aspect of a design can be altered without drastically changing the entire thing, and to make things even more efficient, files can be backed up and duplicated.

Entire designs can easily be duplicated without a lengthy redesign process. To create an alternative version of an already-designed product, you can simply duplicate the existing file, and make your alterations. The process is simple to change things like color, material, and size. This allows product designers to easily create products that are customized for the client.

Able to Create Production Ready Designs

With most modern CAD software packages, product designers can create designs that are as close as possible to being production-ready. Hyper-real virtual renderings reduce the need to create multiple prototypes and allow designs to quickly shift from design to product.

Updated CAD software packages like AutoCAD allow designers to test a design’s integrity against various conditions to see how it would behave in the real world. You can swap in and out materials to see what works best, and perform stress tests to see how it will cope. With all of that said, CAD designs are virtual prototypes – we no longer need a physical prototype.

Unique Problems that Arise with CAD and Product Design

There aren’t too many downsides to using CAD design companies for product designs, and they definitely don’t outweigh the pros of product and industrial design. However, some product designers claim that 2D sketching on paper still is an essential tool.

With that said, there’s room for both 2D drafting and 3D modeling in the product design world. They can and should be used together to create the best product design you can make.

Some believe that when creating an initial draft on a CAD program, designers focus too much on aesthetic and not enough on functionality and solving the problem that the product is supposed to remedy. Some designers may fall into that trap, but combining both 2D drafting and 3D modeling together can remedy that.

CAD Crowd’s Product Designers and 3D Modeling Freelancers Can Help

At CAD Crowd, we take pride in providing entrepreneurs and businesses with the best 3D CAD freelancers on the market. Our network of professionals is pre-vetted, meaning they are guaranteed to provide the best. They’re backed by an accuracy guarantee and the whole process is completely confidential.