Can you believe that the idea of rendering a 3D object was once thought to be impossible? Nowadays, companies specializing in everything from architecture and historical preservation to marketing are using 3D rendering services to help advance their businesses to the next level.

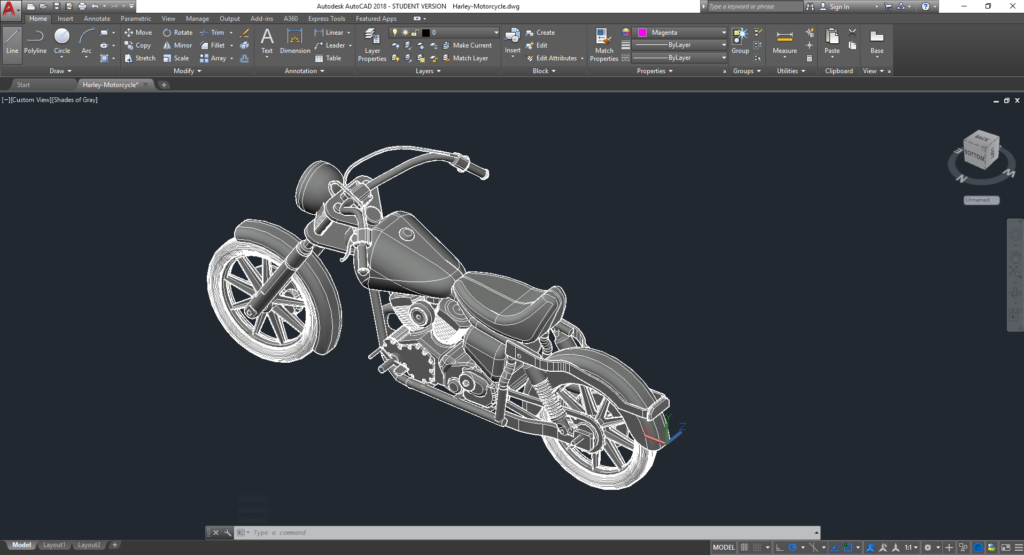

Architectural design services, CAD designers, and engineers are not only able to bring their designs to life with the help of 3D rendering software, but they can also take advantage of virtual reality and real-time rendering to give customers a one-of-a-kind, immersive viewing experience.

For more information on how far technology has come over the years, check out these ten 3D rendering breakthroughs that have helped propel companies to the top of the food chain within their industries.

Top 3D Rendering Breakthroughs

1. 3D Virtual Reality Rendering Services

Once upon a time, the only place you were ever going to see people sporting virtual reality headsets was in a sci-fi film or TV show. Nowadays, it’s a real technology that many people have already gotten their hands on.

Some medical schools have already begun to employ headsets for surgical training. The United States Armed Forces uses headsets to train military personnel without ever having to put them in harm’s way.

Virtual reality is especially useful to CAD designers and architects who rely on dazzling blueprints and artistic renditions to sell their designs to clients and stakeholders.

Even the most artfully drawn floor plans and models can fall short of impressing viewers. That’s why virtual reality technology has become so lucrative in the architecture and design industry. Artists can now create pre-rendered experiences for clients and investors to literally step into.

In the near future, contractors and project managers are likely going to begin performing virtual walkthroughs of buildings to identify potential problem sites before starting construction. Therefore, they’ll need 3D virtual reality rendering services.

2. 3D Printing Services

Rather than being forced to wait several weeks to receive a product prototype, companies are now able to print one within hours. Businesses that manufacture everything from large machine components to fragile products have benefited greatly from this quick turnaround time.

Should they need any replacement parts, they can immediately create interim products from a 3D printer while waiting for the actual part to ship. Sometimes, companies can even use these 3D printed replacement parts permanently.

Architects, in particular, have begun to benefit from the innovation of 3D printing. Back in the olden days, they would have to use an X-Acto knife and a 3-foot t-square to build models of their designs.

Now, they can use 3D printers to create state-of-the-art models. Some architects even use these models to improve their ongoing projects, as they give them a new perspective on their designs that a 2D rendition cannot.

3. Real-Time 3D Rendering

Real-time rendering (RTR) technology was originally used in the video game industry where users quickly rendered games in real-time as they navigated the game’s environment.

So, for example, let’s pretend that someone is playing a video game, and his character is walking through a series of landscapes. Thanks to RTR, the landscape would seamlessly change according to the character’s progression.

This technology has its uses outside the video game industry too. For instance, construction design services and engineers can literally “play through” their designs as they continually update themselves.

In other words, users can walk through a building via a video game in the same way that they would a real-life building. When they make a turn into the kitchen, the environment automatically transforms into a kitchen. When they make a turn into the living room, the environment automatically transforms into a living room.

As of now, it is taking a while for this technology to gain popularity in the construction industry. This is mainly because the costs for developing a video game-like simulation are sky-high.

While technology continues to develop and prices become more affordable, only a small percentage of companies can employ it. Those who do, however, enjoy a significant advantage over their competitors when it comes to their ability to show off their work to clients and investors.

4. Cloud Computing

Nowadays, it seems like “the cloud” is all anyone is talking about. But when considering the vast amount of space it provides compared to that of physical storage, it is no wonder that companies from a diverse array of industries have begun to employ it.

3D technology, for instance, consumes a large amount of space that cannot be stored in any physical container. Imagine trying to fit a file containing several different virtual reality simulations inside a USB drive. You can’t. That’s why the cloud has become so critical to a company’s operations.

Users can now store and retrieve large, complex quantities of data from anywhere around the world thanks to the cloud. The rate at which they are able to obtain these files is much quicker than if they were to attempt to upload them from physical storage.

Not only that, but they are also able to access their files from any location that provides a wi-fi service, regardless of whether or not it is the location where they originally uploaded the files.

5. 3D Capture and Mapping

Data, if accurate, can be a powerful tool for gaining strategic advantage over the competition. When designing elements such as furniture for a virtual reality tour, you will need to ensure that these items are proportionally correct.

Viewers would certainly be confused if they saw a two-inch-wide door next to a 10-foot high countertop. To prevent embarrassing mistakes like this from happening, companies have begun to use 3D scanners to capture accurate mappings of real-life scenes before incorporating them into a virtual reality setting.

Industries outside architecture and film are finding their own uses for 3D capture and mapping. Fashion companies are developing 3D imaging that will capture your exact body measurements. With this information, they can tailor clothes to your individual shape and help you envision yourself in the outfit via virtual reality.

3D mapping is also possible for moving images and film. Artists behind The Hulk were able to use 3D scanners and other advanced technology to accurately map the actor’s movements into that of the Hulks.

By perfecting items inside a virtual environment, companies can seamlessly transition them into a physical environment and dramatically enhance the lives of their users.

Hand tools can be configured for a specific grip to improve worksite safety. Tire treads can be strategically designed to adapt to a specific terrain. There is virtually no limit to what 3D capturing and mapping can do for companies.

6. 3D Model Design and Testing

So, you’ve created your product. Or, at least, a virtual version of it. Now what?

It’s time to put it to the test.

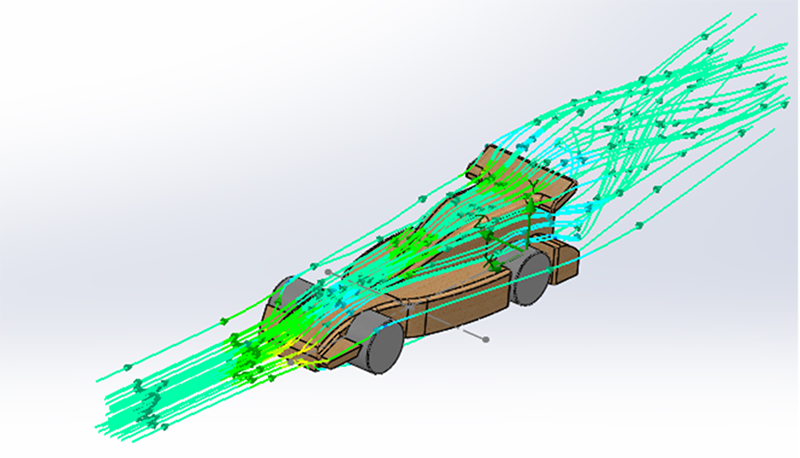

Let’s pretend that you are an automotive design service working on a new prototype and you need to model its aerodynamic flow. You could create a physical version of the prototype and test it in a wind tunnel. But attempting to physically test and retest the car through dozens of scenarios is both time-consuming and incredibly expensive.

Ford Motor Company recently faced a problem similar to this one with its 2020 Shelby prototype. So, to avoid hours of lost time and wasted money, they turned to supercomputers to model the prototype’s aerodynamic flow. Car companies have also used 3D testing for crash modeling. With the data they acquire from their virtual crash tests, they real-time design crumple points that allow the car to collapse without harming its passengers.

Car companies aren’t the only ones benefiting from 3D model designing and testing technology. Bridge designs are tested to ensure stability against high winds and hurricanes. Volcanoes are mapped out to predict lava flow scenarios and create evacuation plans.

The lives that 3D model design and testing has saved, and will continue to save, make it an integral part in the manner by which humans will live and function in the future.

7. Complete Digital Workflows

The best companies are the ones that use the most efficient workflows. Take the Polich Tallix Fine Art Foundry, for instance. Known as “a museum of art being built,” the Polich Tallix Fine Art Foundry has supported artists in the development and production of their work for almost 50 years.

The foundry uses a digital workflow that combines 3D scanning with Geomagic software and wax 3D printing. Thanks to their productive workflow, they have been able to extend their capabilities farther than they ever thought possible.

Thanks to the ever-changing technology landscape, your company is already in a position where it can improve its digital workflow.

3D rendering, modeling, testing, and other innovations mentioned in this article have the power to drastically improve your business operations. However, it is ultimately up to your company to take the initiative to research and employ digital workflows best suited to its practices.

8. Tool-Less Digital Molding

For the past several years, tool-less digital molding has taken the manufacturing industry by storm. Digital molding is a Figure 4 core technology that contains non-contact membrane Digital Light Printing (DLP).

Using the DLP, the technology is able to continuously produce plastic parts in a quick and effective manner. Thanks to its high scalability, digital molding can easily be integrated into automated production lines.

Digital molding is a cost-friendly alternative to traditional injection molding processes, which can take anywhere from weeks to months. Rather than using the old costly injection molding process that is only good for mass production, companies can take their products straight from the CAD design to the manufacturing line with digital molding.

9. Quantum Computing

Computing as we know it is on the verge of changing forever. Ones, zeros, bits, bytes — all of these units may one day become archaic and outdated in the computing industry. Taking their place is a unit that might as well have been ripped from the pages of a science fiction book.

The unit? A quantum bit.

A quantum bit remains uninhibited by ones or zeros. A quantum bit can be found in a variety of potential states, also referred to as superpositions of states.

So how does this translate to computing? In short, it makes your computers lightning fast. Data and computations are processed exponentially faster in quantum computers compared to regular ones.

That being said, quantum computing has not hit the mainstream market yet. While scientists have conducted experiments in which quantum computations were successfully created on a small number of quantum bits, the technology is still years away from becoming ubiquitous in today’s society. Still, rendering artists and companies should keep tabs on this up-and-coming technology.

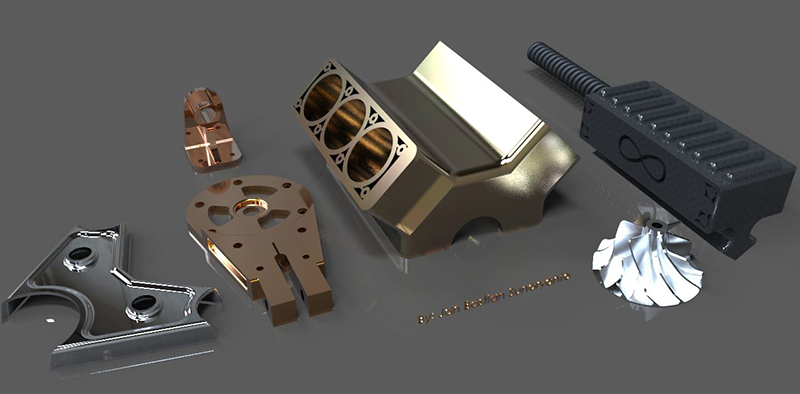

10. Direct Metal Printing

Direct metal printing (DMP) is an additive manufacturing technology that uses 3D CAD data in order to produce high-quality, complex metal parts. Using a high-precision laser, workers are able to build detailed metal layers from metal powder particles. Unlike traditional subtractive or casting technologies, direct metal printers can produce parts with challenging and intricate geometries.

DMP is commonly used for aerospace and defense applications. Everything from a small prototype to a production series comprised of 20,000 units can be made through direct metal printing. Of course, any company that manufactures metal parts with complex anatomical shapes and surface textures can significantly benefit from this technology.

Final Thoughts

Thanks to the digital revolution, companies are able to work quicker and more efficiently than ever. The way in which design and construction firms function today will be incredibly different 10 years from now. Because of the constantly-shifting landscape in these industries, you will need employees that can easily adapt to these changes.

Cad Crowd’s 3D Rendering Professionals Can Assist You

Cad Crowd offers everything you need to safely find and confidentially hire vetted engineers and designers who specialize in 3D design and visualization.

You can be confident that the people you hire will provide quality work that will drastically improve your business. In today’s fast-paced way of living, you can’t waste time attempting to find the right designer for your business. That’s why Cad Crowd is here to help you. Request a free quote today for more information!