Imagine a designer draws up a new product design in the morning, inputs it into a computer by lunch, and by dinnertime is holding a tangible prototype in hand. No waiting months, no tooling downtime, no multimillion-dollar mold expense. Just a smooth pas de deux between concept and creation. That’s not the future—it’s the present, all thanks to 3D printing and its use in rapid manufacturing.

This is the future of rapid manufacturing in any product design services, which you can also get by getting in touch with Cad Crowd, the leading company that helps you connect with over 94,000 3D modeling and design experts who can upgrade your product design without going beyond your budget.

🚀 Table of contents

- Forget prototypes. Think functional parts.

- The real MVP: Speed

- Customization at scale? Yes, please.

- Materials: From plastic to possibilities

- Designers as makers

- The rise of the hybrid designer-engineer-manufacturer

- A case study in disruption: How one design firm became a low-volume powerhouse

- Welcome to the new normal

- The economic shake-up: Hidden savings in plain sight

- Sustainability: From slogan to strategy

- Prototyping for the people: The power of real-time testing

- Microscale 3D printing: Small pieces, huge promise

- Training tomorrow’s designers: A new CAD curriculum

- The bigger picture

- Challenges? Of course. But the payoff is worth it

- The bottom line: 3D printing is not just a tool—It’s a strategy

- Cad Crowd is here to help

Forget prototypes. Think functional parts.

3D printing is no longer a fancy plaything for prototyping, and is no longer relegated to musty design labs where engineers print up bumpy plastic models to share in meetings. Modern 3D printing or additive manufacturing is producing actual, fully functional, end-use parts. We’re talking about aircraft brackets that fly into space, auto parts that withstand abuse, custom medical implants tailored to the millimeter, and consumer-grade gadgets that come off the printer ready to retail. No mold. No middlemen. No months-long lead time. Just design, print, and sell.

This transformation is huge, particularly for product design shops. These are not art studios anymore. They’re becoming mini-factories that can ideate, iterate, test, and make everything in one building. And that makes all the difference.

RELATED: 10 key costs for electronic product design & development rates for engineering services companies

The real MVP: Speed

Old-school product design cycles take a long time. Not just “frustrating delay” long—we’re talking months-long drags through tooling lead times, foreign supplier delays, shipping disasters, and that endless game of email tag with manufacturers.

In 3D printing design services, that same cycle of development that once took 8 to 12 weeks can now occur in a matter of days. Need to alter a hinge design six ways and find out which one is best? Print all six overnight and test them the following day. Want to test how a part will handle actual stress? Print it in the morning, and perform your stress test by lunch.

For design companies, this type of hyper-iteration is pure gold. They’re not languishing with weeks between rounds of revisions. They can experiment, refine, and complete products in the blink of an eye. And if a client comes along on Monday demanding changes, they’re ready with a revised version by Tuesday afternoon. That’s not speed for speed’s sake—it’s agility. It’s responsiveness. It’s being able to say yes to clients quicker than your competition, even when they have time to open their inboxes.

Customization at scale? Yes, please.

Old-school manufacturing excels at making thousands of the same item. But the second you ask for it to be different, the costs go crazy. Tooling modifications, setup expense, scrap, and logistics are a nightmare. Manufacturers don’t want to produce 1,000 somewhat different items—they want to produce 1,000 of the same item.

3D printing, however? Not a whit. It can care less. For a printer, it is just as simple to produce 1,000 distinct parts as it is to produce 1,000 similar parts.

That’s why sectors such as healthcare, aerospace, and consumer electronics device services are swarming to additive manufacturing. A dentist can 3D print a crown specifically for your bite. A medical device manufacturer can design implants formed to an individual’s anatomy. A wearable technology startup can allow customers to customize every aspect of their equipment—from color to shape to function.

Product design companies are leveraging this to provide customers something they couldn’t previously: real, profitable, large-scale customization. No longer constrained by the strictures of mass production, they’re marketing solutions that are high-value, unique, and highly personal.

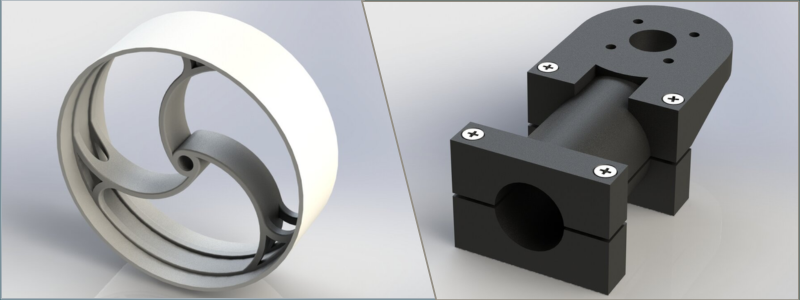

Materials: From plastic to possibilities

Okay, let’s be honest—3D printing previously had a material issue. They are fragile and constructed from low-quality plastics that would break with even a sideways glance. Today’s additive manufacturing materials are game-changers. We’re talking titanium, stainless steel, aluminum alloys, and advanced polymers that can handle heat, pressure, impact, and real-world wear and tear. Need carbon fiber–strength components? Done. Looking for ceramic-level heat resistance? It’s printable. Even biocompatible materials for surgical implants are now commonplace.

This bang in material capabilities translates into designers no longer being able to say, “This looks cool, but it won’t stand up to actual use.” Now they’re saying, “This looks cool and it will withstand a hurricane.” Even better? You don’t have to change for manufacturing. In conventional manufacturing, your design is bound by the capabilities of the tools. Need a hollow internal lattice or an organic form that can’t be molded or machined? Sorry.

But with 3D printing? Production follows design, not the reverse. Designers and engineering firms are now free to make the best possible version of a product, not the easiest one to mass-produce.

RELATED: The benefits of outsourcing custom CAD drafting services for manufacturing firms

Designers as makers

The most thrilling aspect of this entire transformation is how it’s redefining the role of the product designer. Previously, designers were mainly idea people. They’d design, prototype, export files to a factory, and cross their fingers. But now, due to additive manufacturing, they are makers in every sense of the word. They’re not outsourcing their ideas to someone else. They’re printing them, testing them, iterating on them—and sometimes even shipping them straight to customers.

This is particularly potent for startups, boutiques, and solo creators. You no longer require a massive budget or a Chinese manufacturing contract. Your living room can become your factory with the right printer and materials. And for larger companies? It’s an opportunity to streamline. To eliminate waste, to try more ideas, and to get more products to market more quickly. So let’s break the habit of thinking of 3D printing as a prototyping tool, as this is stalling the industry, and your product development process.

Additive manufacturing is no longer about making functional, end-use parts. It’s about speed, customization, and freedom from the constraints of traditional manufacturing design services. It’s about creating smarter, faster, and better. Whether you’re creating aerospace parts, medical devices, or a new breakthrough consumer product, 3D printing can turn your idea into reality, with much less friction along the way.

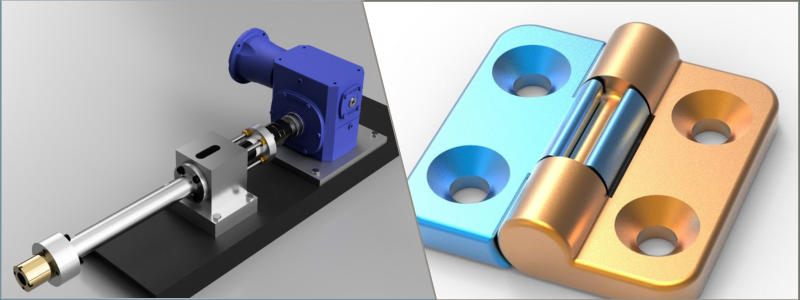

The rise of the hybrid designer-engineer-manufacturer

The product design world is evolving quickly and practically. Before, the position of a product designer existed somewhere between artist and engineer as they envisioned the product, defined the experience, and then passed it along to experts along the way to make it happen. But now? Because of 3D printing and cheap prototyping software, designers aren’t just sketching concepts—they’re creating them.

This revolution is flipping the traditional assembly-line model. Rather than waiting for engineers to translate CAD files and manufacturers to create prototypes, most designers now design everything in-house. One individual can design, print, test, and repeat—right from their desk. The consequence? Shorter feedback loops, reduced miscommunications, and improved final products.

We’re seeing the emergence of the hybrid designer-engineer-manufacturer. The classic silos between departments are eroding. In forward-thinking consumer product companies, product teams consist of individuals who do everything. And often, the entire product process is handled by one individual with the proper tools and attitude.

This doesn’t make factories obsolete, but it does make the hurdle to entry lower than ever. You no longer require a large-scale manufacturing plant to create a product—you require a 3D printer, a creative design brain, and the desire to mess around, test, and iterate.

RELATED: How much does NPD cost? Rates & pricing for services at top design companies

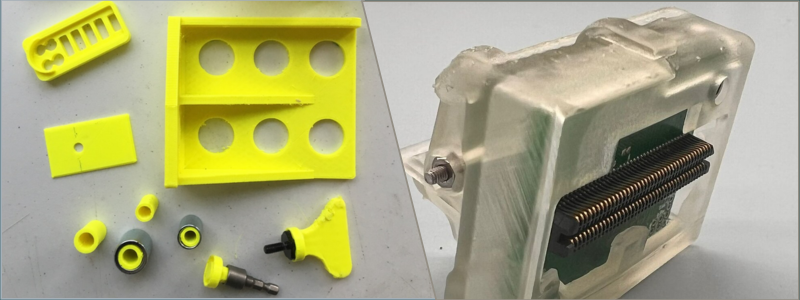

A case study in disruption: How one design firm became a low-volume powerhouse

When a medical wearables startup came to a design services firm for assistance, they didn’t request thousands of units or a massive production facility. They only requested 500 enclosures—small, rugged casings for a wearable device intended for early adopters and focus groups. Previously, this could have taken weeks (or even months) of tooling, a significant initial investment in steel molds, and plenty of waiting around. Not very agile for a business looking to get ahead in a competitive, rapidly changing marketplace.

But then there’s the wizardry of additive manufacturing. With industrial-grade 3D printers, the design company skipped the whole mold-making process altogether. The payoff? A run of 500 working enclosures in less than a week—no tooling, no delays, or drama. From there, the client could test actual devices, collect priceless feedback, and make design adjustments as needed on the fly. Once finalized, they went into full production with confidence, equipped with proven data and not a single wasted mold.

Welcome to the new normal

Increasingly, product design companies are discovering that they don’t require huge volumes to be relevant. They’re adopting low-volume manufacturing as a strategic benefit, particularly in the initial phases of product development. It’s all about producing enough to test, validate, and iterate, without committing yourself to a fixed production pipeline.

Think of it as “lean startup” thinking meets manufacturing brawn.

This method enables design and engineering firms to shift immediately depending on demand in the marketplace, feedback from users, or even unexpected delays—something old-school manufacturing just can’t accommodate.

Now, if you’re not familiar with 3D printing at an industrial level, your initial thought would be, “Isn’t that costly?”

It’s true that specialty materials and high-end printers don’t come cheap. But when you begin to compare that with the cost of traditional manufacturing, it gets very interesting. First off, there’s no tooling, no minimum order totals to achieve, no shipping delays for molds coming from overseas, and no warehouses full of unsold stock. You’re producing only what you require, when you require it.

That lean strategy in itself can be a game-changer for startups and established companies alike. But there’s another secret bonus: the power to fail fast—and repair even faster. Rather than investing three months and several thousand dollars on a defective design, you can spot problems early, make changes overnight, and be back in business by week’s end. That’s a quality of speed and agility that traditional processes just can’t match.

Sustainability: From slogan to strategy

Traditional manufacturing tends to be subtractive processes—cutting or milling away material until the finished shape appears. It’s effective in its own right, but it creates an enormous amount of waste. Additive manufacturing, conversely, is just that—additive. You add up the parts layer by layer, and you only use the material you require. The outcome? Reduced waste, reduced energy, and in many cases, a reduced carbon footprint. It also prevents overproduction. Rather than betting on a massive order of 10,000 units and praying the market reacts, you produce 500, test, and scale on actual-world demand. Design for manufacturability services are utilizing this advantageous aspect of 3D printing.

A few progressive companies are even trying out recyclable filaments and biodegradable plastics, closing the loop on the production cycle. That means yesterday’s prototype that didn’t work could well become tomorrow’s raw material. For eco-minded clients, that level of innovation isn’t only impressive—it’s necessary.

Prototyping for the people: The power of real-time testing

Another underappreciated advantage of 3D printing? It’s revolutionizing the way we gather and respond to user feedback. Suppose you’re designing a new computer mouse that is ergonomically correct. Rather than providing users with a shiny drawing or a foam prototype that doesn’t look at all like the final product, you provide them with a functional prototype that feels substantial. It’s got the right weight, button feel, and shape.

The user comments, “I wish this button were a little higher.” No problem. The design team returns, makes the adjustment, and prints a new version by tomorrow. This type of real-time, iterative testing is a giant step forward in usability. It turns amorphous feedback into concrete results—and quickly. Companies that integrate this loop into their process aren’t just creating better products. They’re creating products that people actually want and need.

RELATED: How cutting-edge medical prototyping design services help your firm design new products

Microscale 3D printing: Small pieces, huge promise

Printing materials with micrometer accuracy, less than the diameter of a human hair, is the new technology. This isn’t sci-fi; it’s being employed presently to create, like, microfluidic devices, MEMS (micro-electromechanical systems), and miniature health care devices, which were out of reach with conventional technology previously.

For medical device design services, high-level electronics, and precision engineering design services, it means entirely new horizons to explore. And then, suddenly, you’re not merely designing something tiny—you’re designing something hopelessly complex, and it’s actually printable.

Training tomorrow’s designers: A new CAD curriculum

Meanwhile, as all this is happening, we are certain that the pipeline of education for product designers is evolving quickly. It’s no longer sufficient to translate mainstream CAD software such as SolidWorks or Rhino. Today’s designers must know about printing techniques, material behavior, support structures, and mechanical stress simulations.

More and more firms expect their designers to prototype and validate their own creations, and this is a selling point of freelance rapid prototyping design services. That means being equally comfortable in digital space and on the workshop floor. In short, the designer of the future is a cross-disciplinary hybrid—part artist, part engineer, part materials scientist.

The bigger picture

What we’re witnessing isn’t just a clever use of tech. It’s a full-blown shift in how products are imagined, created, tested, and brought to market. Low-volume production was once a constraint. Today, it’s a strength. A strategy. A competitive advantage. Design companies that recognize this aren’t merely getting by—they’re flourishing, by creating smarter, faster, and more sustainable solutions than ever. And it begins with a printer, a daring concept, and a willingness to defy the mold—literally.

Challenges? Of course. But the payoff is worth it

No technology is without its challenges. 3D printing still lags behind on production speed in volume, surface finish quality for certain uses, and sometimes, prohibitive material costs. Post-processing can also become a bottleneck—cleaning, curing, or finishing the parts adds time. And although tolerances have come a long way, some high-precision applications might still need to be machined.

But the catch is that product design companies are meeting these challenges head-on. They’re implementing hybrid workflows that integrate 3D printing with CNC machining or injection molding. They’re creating smarter QA procedures and discovering multi-material prints. The reward? Agile development. Customer joy. Quick ROI. And innovation that doesn’t wait for the next fiscal year.

The bottom line: 3D printing is not just a tool—It’s a strategy

At the end of the day, 3D printing is not simply another line item on a product designer’s toolbox. It’s a philosophy. A strategic mindset to creating better products, faster, with fewer obstacles. It frees designers to try things with abandon. It inspires companies to disrupt traditional processes. It unleashes creativity from the shackles of old-school manufacturing.

RELATED: Tips to optimize new invention development and product development for companies

Cad Crowd is here to help

So, if you’re a design company revolutionizing the way products are produced, or a client seeking a versatile, future-oriented partner, 3D printing is the key to a new frontier. And the best part is, we’ve only just scratched the surface. Reach out to Cad Crowd immediately, and we would be more than delighted to provide you with a quote for free.