Shop drawings are essential to the steel fabrication industry and other industries. When an architectural design service designs a new building, they don’t design every individual part from the bolts up. Instead, they may recommend using specific premade items for certain parts, or custom pieces that need to be sent to a fabricator to be made.

Shop drawings are a guideline with very specific instructions on how those custom parts should be made to ensure the safety of those who will use the part afterward—namely, the people who will be building, and eventually working or living in, the building that is being constructed.

Shop drawings include details for these custom pieces ranging from the dimensions of a specific part, how it is to be manufactured, and what the steel should be painted with. The instructions must follow rigorous protocols to ensure they meet all safety regulations and requirements for construction.

No design concept goes into enough detail to make fabrication work, so shop drawings are needed to provide the right detail for creating steel pieces for the building. It’s essential to find someone who is qualified to handle detailed shop drawings for the safety of everyone.

Hiring expert drafters, freelance 3D modelers, and detailers to help with your shop drawings is critical to ensuring your work is safe and accurate. Many of the parts made by fabricators can have disastrous consequences if even the smallest error is made, which means that steel shops need to use only the best to help them reduce inaccuracies.

A professional team familiar with shop drawings in your field can help. Cad Crowd has experienced CAD design services that can help create shop drawings quickly and with minimal errors. This team of professionals will take the data you have from design work and turn it into a more detailed plan for fabrication.

You may think you can skip this step if you already have design drawings, especially if they’re very detailed, but this is a mistake. Design drawings don’t have the details to fabricate a part safely and accurately. You will need both.

Design drawings are part of the design phase, the initial process of putting the concept together. Even at this stage, it will already have the hands of many experts on it, including architects and other professionals. They use this stage to dream up a concept and communicate it to others, including the construction worker that’ll build it.

A concept alone isn’t enough to safely build a building, however. Structural problems can lead to dangerous collapses even if the outside looks pretty. For the sake of everyone involved in the project, it must be safe as well.

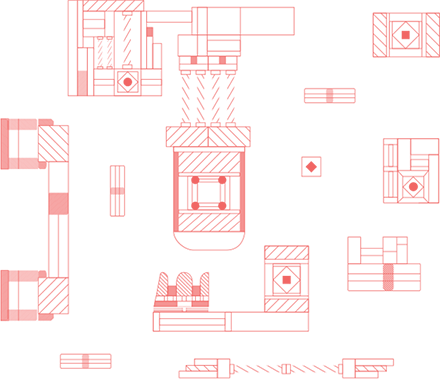

This is where shop drawings come in. Shop drawings focus on how each part is to be made in detail, both as a single part and as part of a whole. Every detail is considered, including where holes must be drilled, their strength, and the dimensions. The precise nature of these instructions is the minimum needed to ensure the project is safe.

Draftsmen, 3D modelers, and CAD drawing services work together to make shop drawings to this high degree of accuracy so that the project, whether it is steel stairs or an entire building, is safe to use.

There are many types of services available for steel shop drawings. After the architect has created a design, it’s usually passed on to people experienced in working with steel. These people take this idea and look at it realistically to see how it can be done. Drawing and detailing is a multi-step process, which usually includes the following steps:

After the architect has developed the design, a steel detailer's job is to take that information and translate the intent into a workable diagram the steel fabricator can use. These plans go beyond just the design concept and detail how each part should be designed.

This can involve many parts, and each part needs to include details such as the materials needed, manufacturing standards, paint requirements, and where any welding or bolting needs to be done.

Diagrams for all steel components need to be drawn up, including details as minor as handrails, all the way up to the steel beams holding the building together. How well these designs are made will greatly impact the safety and ease of construction later.

Large buildings such as skyscrapers can become very complex and require steel detailers with a great degree of experience and an eye for detail to be a part of the process.

Often, steel erection instructions on how to assemble the structure are also created. Steel erection drawings show construction crews the fastest and most efficient way to erect the building. By assembling each steel joist or member in the correct order, you can save time by requiring large machinery like a crane to be moved less often.

Fabrication and detailing are very important steps in creating any project, but they’re not the first. You’ll need to obtain the initial design data from your architect first before sitting down with an experienced CAD designer for the next part of the phase.

The steel detailer’s role is to interpret the data provided by the architect in a form that can be manufactured, which means the more data you have on hand, the better your steel detailer will be able to serve you.

Once the architect has developed their design and submitted the data, shop drawings are the next step towards creating a new building or other large construction projects.

Step 1 - Communication

Your designer will review the architect's data to make sure they understand what the architect is trying to convey. If there are any questions as to the intent of the design, your shop designer will double-check to ensure that the drawings they are making match what the architect is hoping to do.

Step 2 - First draft of shop drawings

Your detailer will create the shop drawings for each building component in great detail. An analysis may be run to ensure that the materials, size, and other aspects of each component meet the necessary safety requirements. Experienced senior team members double-check all the work to ensure no mistakes.

Step 3 - The review process

Accuracy is the most important part of structural steel shop drawings. Because this is so important, a specific review process is designed to ensure almost no errors. The architect will review shop drawings to ensure no errors regarding design intent.

The shop drawings will then be reviewed again by the contractor. The shop drawings will be compared with field notes, the original design plan, and other information to ensure that the shop drawings accurately interpret the architects’ intentions.

Only when everyone agrees that the shop drawings are accurate can the fabricator move forward and use the shop drawing to create the steel parts needed. This is done per AIA standards for the safety of everyone involved in the project's construction.

Cad Crowd can be the missing link between your architect, steel fabricator, and construction workers. Everyone has their part to play in the creation of a building. While the architect creates the design, it’s the responsibility of the fabricator to create the steel portions of the building and the construction worker to assemble it.

Steel shop drawings are the link that holds all of these parts together. A good set of shop drawings takes the architect's knowledge and translates it into a manufacturable form. The same detailers can also provide assembling instructions for construction crews, helping them to put the building together the way it was meant and saving them time and money moving heavy machinery around.

Cad Crowd has a team of experienced steel detailers who are deeply familiar with the knowledge needed for creating detailed shop drawings with minimal errors. They are familiar with AIA standards and will work to help create steel shop drawings that are accurate to the architect's intent.

With Cad Crowd, you can save money by hiring the experts you need for your project without having to go to the expense of finding talent, hiring them, and keeping them on staff between projects. You’ll always have the experts you need with Cad Crowd.

At Cad Crowd, we have a network of manufacturing services who are ready to work on your project. If you'd like help manufacturing a new product, get in touch today. Here's how it works.