3D printing has the potential to change the world in many ways, but one of the most exciting and immediate is how it might revolutionize the way we recycle plastics. Plastics recycling is important but deeply flawed – we see this when we look at the level of plastic pollution in the world, which is reaching epidemic levels.

Plastics pollution is currently a huge problem: 19 billion pounds of plastic are dumped into the ocean every year. The Great Pacific Garbage Patch, an area of increased plastics concentration in the Pacific ocean, is estimated to be between the size of Texas and Mexico. Some experts predict that by 2050, there could be more plastics by mass in the ocean than fish. The profusion of plastics in the ocean affects marine life and seabirds, who often get entangled in items like plastic bags, or choke on the debris. Microparticles of plastic are consumed by marine life, which causes more complex and long-term health problems. This also affects humans who consume marine animals. Freshwater water systems are also becoming clogged by plastics, including urban sewage systems: One 2017 study found that 83% of tap water samples around the world contain plastics. This affects human health very negatively, with plastics targeting the thyroid, endocrine and reproductive systems in particular. Plastic pollution is also a problem on dry land: the breakdown of chlorinated plastics release harmful chemicals into the soil and groundwater, harming local animals and contaminating soil for farming. Furthermore, as plastic degrades it releases harmful methane into the atmosphere, worsening climate change.

The process of plastic recycling can’t be entirely blamed The causes of plastic pollution are diverse but can be placed into two general categories: plastics not getting recycled when they could be, and the difficulty in recycling plastics even when they end up in the right place. 3D printing has the potential to alleviate both problems.

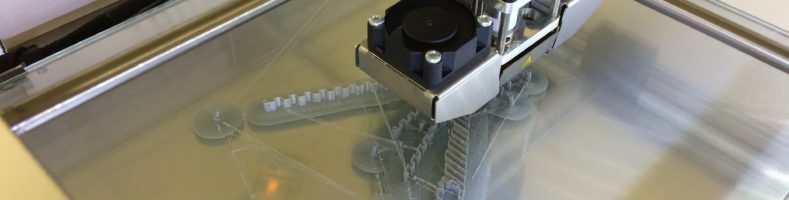

Before we get into the specifics, it’ll help to have some background on how plastics recycling works. In conventional recycling, plastics are often made to undergo intensive heat and chemical reactions in order to alter their form and composition. Some plastics undergo a process called thermal depolarization to turn them into cheap fuel. Others undergo heat compression, where unsorted plastics can be combined and turned into a recycled form. Some forms of plastic, like polyethylene terephthalate, are broken down into flakes by large machines and then fused back together to form different products. Some plastics are used as a carbon source in steel recycling. All of these methods have their advantages and disadvantages, but 3D printing has a few key advantages over all of them. In plastics recycling for 3D printing, plastics are sorted by type, and then pulled into long plastic filaments – the “ink” of 3D printing. These 3D filaments can be fed into a printer to produce a wide variety of models, shapes, products or prototypes.

Studies have shown that while recycling levels have risen in all categories of materials since 1990, they’ve lagged behind in plastics relative to the others. One reason for this is economic; plastics are one of the most expensive and least profitable materials to recycle. Due of the complexities of plastic recycling, it can be confusing which kinds of plastics can be recycled and which ones can’t. It makes sense that companies and individuals and might be more motivated to recycle when the process is more straightforward and lucrative, as it is for metals and glass. There can also be a disincentive for the recyclers themselves: for many types of plastics, the margins between the cost of recycling and the market value of the end product can be slim. 3D printing has the potential to increase plastics recycling rates by making recycled plastics a lot more valuable. With a whole new method and application for plastics recycling – one with a wide range of applications – plastics might even become more valuable to recycle than metals and glass. And, as we know from basic economics, the best way to make people do something is to attach a dollar value to it.

According to an article in the Guardian, 3D printing is already making a huge difference in the lives of waste pickers in India – that is, people who make their living going through garbage heaps. Plastic waste prepared for 3D printing net six to eight times the amount that plastic would when prepared for traditional recycling. These margins are sure to increase in the coming years, as 3D printing is expected to increase its market share 261% by 2012.

Another benefit of 3D printing over traditional methods is that plastics can be converted into filaments cheaply, easily and without the need for high temperatures or expensive equipment. Unfortunately, as with traditional recycling, plastics recycled into filaments lose their durability and quality each recycling cycle. However, when it comes to some 3D printing applications, this might not be that big of a deal. Many businesses and inventors use 3D printing to produce cheap models for short-term use – in these cases, lower quality filaments might be less of a problem. Furthermore, it seems that a wide variety of plastics would work as 3D printing filaments, again depending on the intended application.

As the benefits of recycling plastic for 3D printing stack up more and more people are turning to this approach over conventional recycling, some in their own homes. Three students at the University of British Columbia invented a machine called the ProtoCycler, which takes plastic waste and converts into in 3D printing spools. The ProtoCycler costs $100, which may seem like a lot but is much less than multi-million dollar recycling facilities. In the future, recycling could be less of an institutional process, and more something that everyone does in their own homes, producing the raw materials out of which they can build new things. Imagine a world where, instead of going to the store to buy an iPhone case, you feed some plastic bottles into a machine and print one off in your own living room.

Some 3D printing experts are looking into developing biodegradable plastics for use in this industry. When combined with plastics being recycled into filaments, we could eliminate the need for new plastics to be produced altogether. This would be a massive boon to the world’s ecosystems, and to human health.

Do you have an awesome idea to be carried out by 3D printing? Get in touch for your free consultation with Cad Crowd’s team of freelance design experts.