On average, over 30,000 new products are launched onto the market every single year. Additionally, over 627,000 new businesses open annually. However, 95% of new products fail within 12 months and are pulled from the market; and every year, over 595,000 businesses fold within that same calendar year.

This is the chilling world of market expansion and capitalism that exists today. It’s effortless to start a business or launch a product, but it’s so much more difficult to find commercial or critical success. With this turbulent marketplace, it’s crucial to be able to create and market a new product for your business as efficiently as possible.

Rapid prototyping is the cutting edge of technology when it comes to product development. If you are willing to introduce a new product to the market, run some tests on something in development, or even make a fun little trinket for your keychain, rapid prototyping offers numerous advantages that can impact your life and business in monumental ways.

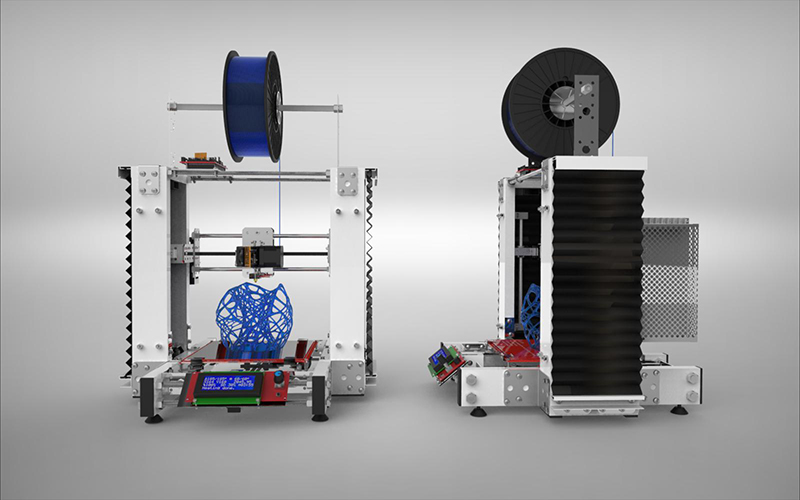

In fact, 3D printers have even been sent to the International Space Station, replacing a number of their everyday items and tools with a newfound ability to print tools and devices as they need them. These high-quality, essential tools are for a group of people whose very lives depend on the functionality of these products. 3D printing and other forms of rapid prototyping are becoming increasingly more reliable, to the point where most products are indistinguishable from their initial prototype versions.

The obvious benefit is the speed and ease at which you can create a prototype with these manufacturing methods. As long as you have the digital file, you can typically have a product completed in a few short hours, and you’ll be prepared to proceed with whatever next step you need to accomplish. Aside from the speed and functionality of these methods, however, there are several advantages rapid prototyping offers your business.

With 95% of products failing in their first year, competitive advantage and a quick turnaround can make all the difference when it comes to ensuring your product is profitable and successful in today’s business climate. Let’s take a look at several advantages below.

Benefits of Rapid Prototyping

1. Customization

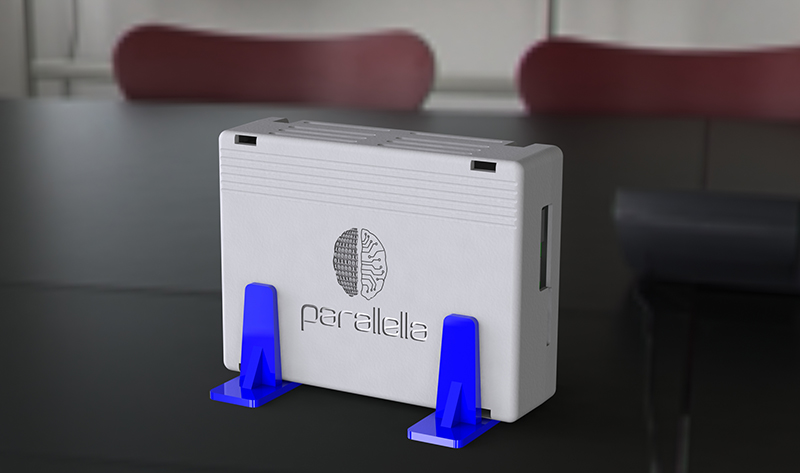

One of the most significant opportunities surrounding rapid prototyping services is the chance for customization. First of all, being able to differentiate your product from others on the market is vital if you want to stand out and be memorable.

Let’s look back at the illustration of the astronauts on the International Space Station. 3D printing is just one aspect of rapid prototyping, but it’s a good representation of the capabilities that this process can offer.

The astronauts need extremely specific items and tools, each one individualized for their various responsibilities. You don’t want the same drill to unscrew a delicate air filter in the ventilation shaft of the space station that you’d want for mounting solar panels to the outside.

So, the 3D printer offers them a chance to make two different drills or screwdrivers to ensure they have the appropriate tool for each project.

Even better, imagine an Apollo 13 type scenario, where the astronauts are in desperate need of a tool or part they don’t have, and never imagined they would need. Say something broke in the environmental control system, and they’re overheating, so they need to create a connector to channel the heat from the HVAC system into another duct.

This isn’t a scenario they knew they would experience, so they don’t have any tools or supplies for it. But a 3D printer can let them design and print the exact product they need, solving practically any challenge that is thrown their way and potentially saving their lives.

Hopefully, the customization of a product you design won’t have your life riding on its success, but it can drastically help your business.

Competitive advantage is key in product design, and being able to take a standard product that you’re planning to create and adding in any number of features will give you just that. Rapid prototyping allows you to customize the product however you want, even if you want to try out ten different customizations to test which one works best.

Additionally, for special promotions, esteemed clients, or other situations, you may want to create a unique, one-of-a-kind version of your product for limited release.

This kind of customization is becoming a very stylish marketing tactic, and rapid prototyping can create those products for you at a moment’s notice. No need to wait around to manufacture a limited run and spend extra money on it—you can print them out and ship them to customers instantly.

2. Reduced Costs

This one is big. Reducing costs is vital, especially for a small company that is just starting out, or one that is trying to squeeze every drop of price out so they can beat their competitor’s in the market. Rapid prototyping gives you much more control over your costs and allows you to reduce them drastically while still producing a magnificent end product. There are numerous ways it can reduce the cost of your prototype, and we’ll dive into a few right here:

- Reduced fixture and machine costs

Depending on the product, designing and making a fixture or purchasing a new machine can be incredibly costly. We’re talking hundreds and thousands of dollars costly.

For a small product that I once designed, an electrical socket for mining equipment, the fixture cost, made of aluminum, was around $7,500. Fortunately, we already had the correct press to do injection molding with but had we not, the machine would have run around $120,000.

However, instead of designing and purchasing that immediately, we 3D printed the part from an outside company and purchased a set of 20 pieces for under $750. That allowed us to test and reconfigure the design so that we made sure the product would work before purchasing the mold.

- Reduced lead time

Creating molds and getting everything set up to produce a product takes a lot of time, and as anyone in business will tell you, time is money. By reducing the time it takes to produce a part, you give yourself more time to accomplish other things with your business, such as marketing or testing. This is a valuable time to get your product launched.

- Reduced material costs

This one is optional, but in many cases, the first iteration is not the final production material. For instance, you may CNC an aluminum product, which will end up being made of copper or steel. You may choose to create a plastic 3D printed sample of something that will eventually be ceramic.

It just depends on what your goal is with the prototype—is it for testing the material characteristics? Do you need to understand the form, fit, and function? Is it solely for marketing and presentation? Whatever the solution is, you can choose the most cost-effective option with rapid prototyping and save some money.

3. Higher Profit Margins

Higher profit margins go hand-in-hand with reduced costs, obviously, but there are some hidden variables. Obviously, you can cut your costs, but there is one other significant benefit that contributes to higher profit margins, and that is you don’t have to worry about economies of scale.

Certainly, there is always a benefit economically to purchasing more pieces at one time, but 3D printing is not entirely so reliant on that scale for its price. Much of the price improvement is the fixturing cost being spread out over a more significant number of pieces.

With 3D printing or rapid prototyping, this fixturing is unnecessary, just by the nature of the beast.

With no associated fixturing cost, the price per piece, as we’ve shown, goes down substantially. This means that you will be able to make the same profit margin on the first 50 pieces sold as the next thousand.

That additional income is invaluable to your business. For instance, if you are under a heavy financial constraint but are attempting to produce and sell a new brand of a cell phone case, you may be in a bind.

It costs $5 per case sold if you only plan to sell 50 of them, which only gives a slim profit margin, and that may not be enough to fund the next steps in your venture, sending your new company out of business pretty quickly. To make the necessary profit margin, you’d need to get that price down to $3 per case, but to do that, you’ll have to buy in bulk, purchasing potentially a thousand or more.

Either way, your company is out of money pretty fast. But if you could get the initial run of 50 cases for $3 per case, you could sell enough to take the next steps in your business, maybe even preparing fixturing so you can get the price down even further.

Rapid prototyping gives you that option because you’re not paying upfront for machinery or molds—just the time and material it requires to 3D print or prototype the product, at which point you’re ready to sell.

4. More Sales

Sure, rapid prototyping can reduce your costs and improve your profit margin. It’s a fantastic tool for manufacturing, but can it help with marketing and sales?

That seems like a tall order, but interestingly, it has been used for just such a thing. In fact, as early as its inception in the 1980s, 3D printing has found selective use in the world of marketing, offering a more objective view of a product than had ever been imagined before.

3D printing offers something no other marketing campaign does—a chance to see and use the product. Compared with photo or video of an object, it is extremely tough to match the impact of seeing a realized piece sitting in front of you that you can see and hold.

Many times, the products we see advertised are not quite as they seem, such as a shirt that doesn’t quite fit the way it was supposed to or a watch that’s not as much “rose gold” as it is “Hello Kitty pink.”

There’s no getting around this unless you can see the product in person. Rapid prototyping allows us to market real products to individuals that they can see and feel, interacting with them as they would once they’ve purchased them. It’s like a test drive for every product you could imagine.

This is especially useful in highly specialized and customized fields. Once again, customization is a massive benefit of this process, but here it can be used to prototype a particular product for a client who may only be considering purchasing it.

By creating a prototype, they can see the exact product on display, instead of some stock photo of a similar product with a promise to add in the features they’re asking for. There will be much more confidence if they can see and hold the product in their hands.

A great example of this comes from the International Manufacturing Trade Show in Chicago in 2014. A company 3D printed an entire car, chassis, engine, wheels, and all in their booth throughout the weeklong show, and drove it out of the exhibit. There is no better marketing campaign than showing someone the products you can produce, and how quickly you can do it.

5. Instant Feedback

At all levels of the process, feedback is critical. In fact, many of the stages of product development center entirely around feedback. The Voice of the Customer is a type of feedback where you hear what the market demands and hates about certain products.

Product testing is gathering quantifiable feedback about the performance of a product. In every stage, feedback is how you will evaluate, improve, and adapt your product to the needs and whims of the market. With rapid prototyping, feedback is quicker and better than ever.

Using rapid prototyping or 3D printing creates a realistic and testable product, which is one of the most crucial phases of feedback. With a real product in front of you, you can simulate any test that comes to mind and actually figure out if the product performs the way it’s supposed to.

Instead of waiting around to see if your CAD drawing will turn out right once you’ve purchased the manufacturing machine to make the product, you can crush it against the side of a wall and see how well it stands up, giving you instant feedback.

The major problem of design without prototyping is that you can’t adequately gauge the performance of a product without having the actual product complete and manufactured, and often, the associated costs of getting the manufacturing up and running are so prohibitive that you can’t ever launch the product as you want.

Beyond the testing phase, your company will get feedback at another crucial phase that is as important as ever—initial user testing. You can send the actual product to potential customers and have them use it.

This accomplishes two things—first and foremost is it evaluates the product and compares it to the initial voice of the customer. If they don’t like your product, you will certainly know, and you’ll have some feedback to work on.

Second, however, is building an identity and some loyalty. If your customers see the good faith effort you’re putting into making a quality product, they’ll respect you for it. Obviously, you will always end up doing user testing, but rapid prototyping makes it faster as well as cheaper, allowing you to test it with a wider range of customers.

6. Better Market Visibility

Market visibility has a significant cousin, and this is what will give you a competitive edge by using rapid prototyping. That cousin is market penetration, or market saturation. The faster you can get products to the market, and the more products you can get out there, the more name recognition you will have.

This strategy is currently being employed with great success by none other than Mattress Firm. I would bet a large sum of money that you have a Mattress Firm on a street corner near you, and it’s just as likely that you have three within the same distance from your house. This campaign is actually very useful because they’re pushing their visibility to a point where, when you think of mattress stores, you initially think of Mattress Firm.

As they engrain themselves into the consciousness of Americans everywhere, they also push competitors out of the way. When this task is complete, and they’ve gained a solid market share, they close down the underperforming stores and consolidate them into the most profitable location.

You likely won’t do exactly that, but the concept is similar—you will push your product out there as much and as quickly as possible. The more you get the product out there, the more well-known your name is. Rapid prototyping gives you a huge advantage in this arena, in fact, several advantages.

First, you have the advantage of time. It takes so little time to begin and complete rapid prototyping that you can probably get products to customers before you finish writing your business plan (from a business perspective, I would advise against this, but it’s your call).

Another advantage is cost, like we discussed earlier. You can produce many more pieces for the same price or even less than many competitors, so you get double or triple the market penetration, and therefore visibility.

Most importantly, however, you put a high-quality product on the market. The products you create with rapid prototyping will be made to a very high standard because the process is very refined and the tolerances are fantastic.

Once you put these products on the market, consumers will beat a path to your door to continue buying from you, and by then, you’ve already succeeded.

7. Higher Complexity

A final benefit to rapid prototyping is the level of complexity you can manufacture into your products. In some cases, the complexity level is so high that companies will decide to transition to solely 3D printed or rapidly prototyped products because it beats the complexity their own machinery can craft.

If you’ve ever watched a 3D printer in action, it offers a stunning visualization that you won’t get anywhere else—the complexity of internal structures as they’re being created.

3D printing can create things so complex and delicate that it can mimic the structure of internal organs, and people have even received 3D printed veins and arteries through various surgeries. That level of complexity is mind-blowing, and if you can incorporate even a tiny fraction of it into your product, you will amaze any potential client.

At one point, performing product design services for a prior job I was working on, we created some 3D printed prototypes to test out for our product. After creating them, my boss came to my desk and he had to explicitly ask me to “dumb down” the designs.

The structures of the prototype were too complex and delicate, and our manufacturing process would be unable to replicate them as it stood at that time.

We were creating designs that a fully functional manufacturing plant for a multi-billion-dollar corporation was unable to replicate, and we were doing it faster and cheaper than they could imagine.

When we did destructive testing to measure crush strength for these pieces, they outperformed our aluminum cast ones, simply because the internal designs were more intricate and sturdier.

That is why so many companies are turning away from traditional manufacturing and focusing their efforts more on 3D printing and rapid prototyping. This kind of complexity can amaze customers and draw them in, even if they are only display and marketing elements.

The industries that require complexity have turned their attention to rapid prototyping services, because they can suit their needs better than anything else. The fields of aircraft manufacturing, space technology, and medicine are all utilizing this technology for things like internal engine pieces, fuses and nozzles, entire satellites, rocket engines, kidneys, and arteries. If they can use 3D printing, I’m sure your company could find a use for it.

Rapid Prototyping Is the Future of Product Development

Rapid prototyping is legitimately the future of product manufacturing, design, and testing, and will eventually revolutionize the world. The hypothetical future of technology – the “Bucket of Stuff” – is around the corner, and it starts with 3D printing and rapid manufacturing and prototyping.

Hypothetically, one day, technology will develop that will allow you to reach into a bucket of some amorphous material and pull out the exact product you need, mainly 3D printing something in seconds. This technology is that which we’re staring in the face, observing 3D printing become more and more capable and used in more incredible industries.

The advantages for your business are immense and hard to ignore. Regardless of whatever product you’re attempting to bring to the market, rapid prototyping will make that transition smoother, faster, and more profitable.

As long as you have a designer and prototyped who is skilled with the technology, you can get through the process with immense ease and create something to blow your clients away.

Cad Crowd’s Rapid Prototyping Freelancers Can Help

Contact Cad Crowd to find a qualified and trusted 3D designer or rapid prototyping engineer to complete your project for you, and you won’t regret it. The benefits are staggering.

We could list the numerous companies who choose to use this technology or the variety of new methods that are cropping up practically daily to meet the world’s increasing demand for rapid prototyping, but we’ll leave you with an examination of the beautiful benefits the technology can offer you. Take a look at everything it can do, and don’t hesitate to jump on board with the wave of the future.

Take a look at how it works or contact us today to get a free quote if you’d like to get started right away.