So, you’ve got an idea. A product idea. Maybe it’s a game-changing kitchen gadget, a smart wearable for pets, or a sleek piece of exercise gear that folds into your coffee table. Whatever it is, one thing’s clear: you can’t build it alone. That’s where a product design firm or a skilled freelance product designer from the industry leader Cad Crowd comes in. But finding the right one? That’s kind of like dating. There’s chemistry, there’s trust, there’s the first awkward meetings, and hopefully no heartbreak.

It’s not about creating something that “looks good.” It’s about bringing your idea to life, making it manufacturable, functional, and desirable. It’s a path from sketchbook to prototype, and then on to something that sits on a shelf (or finds its way onto a TikTok shopping haul).

But don’t worry. You don’t have to be an engineer, an artist, or a Silicon Valley visionary. You just need to know what to look for. Here’s your whole guide to hiring a product design team that won’t ghost you after the first render.

🚀 Table of contents

- Why you can’t skip the pro team

- The big questions you should ask before you sign anything

- Behind the scenes: What product design firms actually do

- Red flags that shout “Run!” when selecting a product design agency

- How much does this actually cost?

- Should you hire a firm or a freelancer?

- What great designers and firms have in common

- How long does it take?

- Working with a design firm: Tips for a smoother ride

- Design is where magic meets mechanics

- Cad Crowd is here to help!

Why you can’t skip the pro team

Product prototyping isn’t about cobbling things together with hot glue and prayer. It may be tempting to rely on a tech-savvy uncle who has a 3D printer, but there is a huge gap between a homemade mockup and a professionally designed prototype that can really sell. That’s where an experienced product design company comes in—and why bypassing them can be more expensive in the long term.

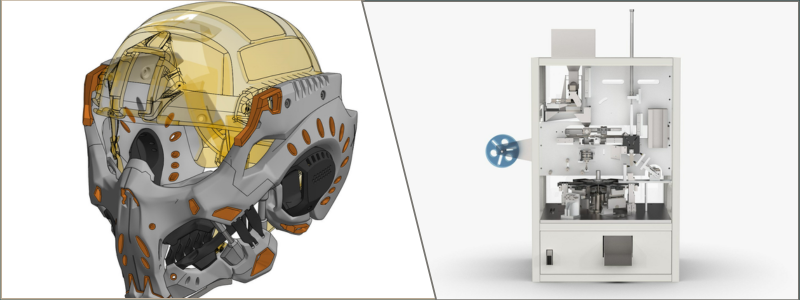

The pros bring more than just tools. They bring a multi-disciplinary team: industrial designers who focus on aesthetics and usability, mechanical engineers who obsess over structure and durability, CAD specialists who translate ideas into manufacturable models, and materials experts who know exactly what will work (and what will melt under pressure). If your idea includes electronics, electrical engineers are often part of the lineup, too.

But the greatest value isn’t merely technical expertise. It’s the critical thought that goes into each choice. An expert team understands how to ask the proper questions: Will this work in the real world? Is it safe? Can it be produced at scale and economically? And perhaps most importantly, will it delight users?

Collaborating with a professional product design company isn’t about delegating your concept; it’s about getting it right the first time. Since the journey from idea to reality is riddled with make-or-break moments, you want individuals in your corner who have successfully traveled that path and who know exactly where the potholes lie.

RELATED: How is product design different from industrial design services companies?

The big questions you should ask before you sign anything

Imagine this: you’re in a modern conference room, with an espresso cup nearby, surrounded by pristine sketches, polished prototypes, and excited designers who are obviously proud of what they’ve made. It’s easy to jump in headfirst, give the go-ahead on the project, and envision your product launch going viral. But before you become carried away with the euphoria, it’s time to put on the brakes and demand the hard questions, especially the ones that can make or break your project later on.

Q1. Have you developed products similar to mine?

Experience in your particular category of products is not a plus; it’s a necessity. Creating a smart wearable device is different from creating a new chair or kitchen gadget, even for product design firms. If your product has electronics, wearables, moving pieces, or has to meet exacting safety requirements, you need a partner who’s already familiar with that landscape. Request examples. Case studies. War stories, even. A team that has “been there, built that” will keep you out of expensive side roads.

Q2. Do you do everything in-house?

Not all design companies are equal. Some provide full-service solutions from ideation and sketching through prototyping and factory-ready files. Others might subcontract work such as CAD modeling or prototyping to outside vendors. That’s not necessarily a bad thing, but it’s important to know who’s actually performing the work. You don’t want to find halfway through a project that your prototype is being sent half around the world, or that essential design files are handled by some nameless freelancer. Transparency is essential.

Q3. What’s your prototyping process?

This question says a great deal about the company’s technical ability and how seriously they are taking your vision. Are they handing you 3D prints glued together with super glue, or are they giving you high-fidelity prototypes that closely represent the final product? If your project is being presented to investors or you are going for crowdfunding, appearance and function count big time. A professional prototype created with CNC-machined aluminum or molded plastics says you mean business.

Q4. Can I own the IP?

You’d be amazed how many business people sweep this one under the rug. Intellectual property is everything. Your name on the patent application, your brand on the design, and your rights locked in black and white. Contracts must be cut-and-dried: you own all IP created under the project. No gray language. No co-ownership. No “we retain rights on particular components” provisions. If the design company resists this, it’s a warning sign.

Q5. What is the DFM (Design for Manufacturing) plan?

A gorgeous prototype is only half the journey. The real magic happens when that design is ready to roll off the production line efficiently and cost-effectively. That’s where DFM services come in. If the design team can’t explain how your product will be manufactured at scale, or worse, they haven’t thought about it at all, they’re not building a business; they’re building a one-off model. Ask how they handle production constraints, material choices, and supplier communication.

Short and sweet, enthusiasm is wonderful, but preparation makes it perfect. Ask these questions, make notes, and don’t accept vague replies. Your product and your company deserve clarity and competence from the beginning.

RELATED: Key factors to consider when vetting engineering firms for design & consulting services

Behind the scenes: What product design firms actually do

When someone hears “product design firm,” they might envision a group of creatives rolling up their sleeves and batting out chic 3D drawings and presenting them with a flourish. That may be the superficial tip of the iceberg, but what actually goes on behind the scenes is an awful lot more complex, strategic, and team-based. A product design company doesn’t merely make things look nice; it assists in shaping ideas into producible, marketable products. Here’s a greater insight into what the entire process actually entails.

Phase 1: Discovery & concept development

This is the time your idea gets to take its first breath. You arrive with sketches, inspiration boards, or perhaps just a rough idea in your head. The concept design service team has its own weaponry, which includes whiteboards, post-its, coffee-fueled ideating, and lots of curiosity. The intent here is to understand user requirements, market voids, and product objectives. Don’t worry if your original concept gets remolded or questioned. The whole point of this phase is exploring and distilling down a vision that’s innovative and realistic.

Phase 2: Industrial Design

And now the party starts. This is when the visual identity of your product comes into being. Designers consider ergonomics, aesthetics, user interface, and visual effect. They create concept illustrations, create mood boards, and start modeling initial designs in CAD. But it’s not merely creating something pretty; however, it needs to be right and act naturally for the end user. It’s where form and function come together in an explicitly intentional and user-oriented manner.

Phase 3: CAD modeling & engineering

Design concepts are passed on and developed into precise 3D models. Engineers come aboard to sort out the nuts and bolts: materials, component location, load tolerances, and mechanical systems. CAD packages become the collaboration language of first resort. All the way down to screw holes and cable run, everything is carefully specified. This is the stage where the design team begins to answer the essential question: Can this even be built?

Phase 4: Prototyping

Now that the digital work is complete, it’s time to go physical. With additive manufacturing services, CNC machining, and other rapid prototyping tools, the product begins taking form in the physical world. This isn’t for display purposes alone—prototypes are examined for feel, fit, strength, and usability. Can the hinge withstand repeated use? Does the button provide proper tactile feedback? It’s all about checking the design and identifying what needs to be corrected before proceeding.

Phase 5: Refinement & pre-production

Prototype is followed by a cycle of feedback and revision. Perhaps the material selection must be tailored, or the transformation could be more ergonomic. The team makes product refinements based on field testing and stakeholder feedback. Engineers validate that the design is suitable for mass manufacturing, streamlining assemblies, minimizing components, and maintaining cost-effectiveness while preserving performance.

Phase 6: Handoff to manufacturing

Lastly, the design is ready to face the world. Detailed CAD files, production drawings, and bills of material (BOM) are complete. Some companies even help with finding manufacturing design companies or taking orders from vendors. Everything is now ready to go smoothly from the design studio to the shop floor.

So no, it’s not all about fancy renders. It’s an intense development process, significant collaboration, and an infinite number of iterations all to create a product the correct way.

Red flags that shout “Run!” when selecting a product design agency

A beautiful portfolio or crisp website can be extremely convincing, but remember, do not be seduced. Even the most professional-looking design agencies can be a bad fit when you look beyond the surface. Before you sign the contract, here are some serious red flags that should make you reconsider the arrangement.

Number one: no physical prototyping abilities. Great digital renders, perhaps, but if a company can’t create and test physical prototypes, how will it determine true-world usability, longevity, or fit? A design that exists solely on a screen isn’t very helpful once consumers hold it.

Then there’s the abhorred one-size-fits-all strategy. Your product is specialized if it’s a niche or combination design, such as a smart lock with a skateboard attachment. If a company appears to be using the same process with each client, it probably means they’re not customizing for you.

Another dealbreaker is the lack of understanding of production. A stunning concept, in the minds of some designers, is the last step in their work. But if production is too expensive or impossible, then the design serves no use. From the very beginning, the top product engineering design companies think about production limits.

Listen to what they say, too. If every other sentence is full of industry jargon but you still don’t have a clue what they’re talking about, that’s an issue. Clean communication is important. If they can’t describe their process in simple English, then they probably don’t even know it well themselves.

Lastly, ambiguous pricing and schedules should cause you to pause. Experienced firms know how to estimate costs and timelines. If everything seems fuzzy or TBD, that’s a big red flag that they’re not yet prepared or inclined to commit.

Bottom line: trust your gut. If it doesn’t feel right, it likely isn’t.

RELATED: A guide to electronic product design for manufacturing with PCB design firms & engineers

How much does this actually cost?

Yes, the money talk. It’s not really anyone’s favorite subject matter, but if you’re truly determined to introduce a new product, you can’t afford to brush it under the rug. So, how much does product design and prototyping really cost?

If you’re creating a simple consumer product, like a kitchen appliance or a simple plastic box, the costs usually range between $15,000 and $50,000. That usually covers everything from preliminary concept drawings to a functional prototype. But it gets a little more serious (and costly) when you enter into complicated territory.

Products that encompass embedded electronics, specialty materials, or rigorous safety protocols, such as medical devices or wearable smart things, can easily drive the price to $75,000 to $150,000, and even higher at times. These are not merely frilly figures. They represent the broad engineering, prototype design engineering service, and regulatory hurdles involved.

Now, sure, freelancers tend to hit the market at more affordable price points. If you’re a startup struggling to get traction on a shoestring budget, you may see quotes ranging from $5,000 to $10,000. Sounding pretty good, right? Well, here’s the problem: that $5,000 design may never actually be produced. If it can’t be manufactured, or it doesn’t work when put to use in real-world applications, you’ve pretty much wasted money with nothing to show for it.

So what are you actually paying for? Not just doodles. It’s about expertise, productivity, and problem-solving. An experienced team understands how to avoid the types of errors that kill a project several months into the process. And where each delay costs more than dollars, time, opportunity, and momentum, it will become apparent that wise investment early on often translates to better returns down the line.

Short answer: Cost is important. But the value is more.

Should you hire a firm or a freelancer?

It’s a typical dilemma for anyone creating something new: do you hire a full-fledged design agency or a lean freelancer? The response isn’t one-size-fits-all. It actually depends on the scope of your project and how involved you want (or need) to get.

Design companies send a whole team along. Consider industrial design experts, CAD specialists, mechanical engineers, prototypers, and sometimes even supply chain experts. If your item is complicated or if you need someone to guide it from the first sketch to full production, this one-stop shop experience can be a big winner. You receive organization, accountability, and often an efficient process.

Freelancers, on the other hand, provide a concentrated and flexible solution. Perhaps you only require CAD drawings. Or a nice product rendering. Or an outside opinion on a mechanism that’s been stumping your team. Freelancers tend to be cheaper, and they typically are quicker to get up to speed. The catch? You’ll be responsible for coordinating other aspects of the project, such as electrical engineering, procurement, or end prototyping.

The third option is à la carte services, where you can access their expertise without purchasing the entire ticket. Need just a prototype? Or want a design audit before you invest in tooling? These companies can step in at a halfway point and provide specific support holes.

Ultimately, it’s all about connecting the right talent with the right point in your product journey. Whether that’s the power of a firm or the flexibility of a freelancer is a matter of what you’re building and how you want to build it.

RELATED: How to reduce painful product development costs for your company

What great designers and firms have in common

When you’re in the market for a design partner, whether it’s a freelance pro or a full-fledged consumer product design firm, it’s easy to get distracted by beautiful mockups and slick presentations. But great design isn’t just about looks. It’s about working with someone who truly gets what you’re building, why it matters, and how to make it real.

One thing that distinguishes good designers from great ones?

- Curiosity: Great designers won’t simply nod and agree with anything you propose. They’ll ask intelligent questions regarding your users, your business objectives, and even your competition. That’s how they adapt solutions to what you really need, rather than what you believe you do.

- Candor: If your idea has a hole in it, you want someone who’s honest enough to say so and skilled enough to offer better alternatives. No sugarcoating. No unnecessary flattery. Just useful, constructive feedback.

- Collaboration: A good designer understands that this isn’t a one-and-done deal. They’ll listen attentively, articulate their decisions clearly, and shift their strategy as your project unfolds. It’s a two-way conversation, and the best ones ride with you each step of the way. Just as crucial is a production mentality. A design that appears stunning on the screen but is prohibitively expensive to produce is a dead end. Great designers know how things work in production and design accordingly.

Lastly, the results are not simply nice shots, but products in the real world, rave reviews, and case studies that speak to their effect. Specific client testimonials can say more than any portfolio ever could.

Bottom line: Brilliant designers pose intelligent questions, provide frank responses, collaborate like teammates, and realize your ideas in style and function.

How long does it take?

How long do products actually take to design? If you were thinking of getting it all done in a few weeks, think again. A full product design process from your first concept to production files is typically 3 to 9 months, and sometimes more. The timing depends on complexity, especially in the case of electronic device design firms.

For instance, a straightforward plastic product can be done in 3 or 4 months. But if you’re working on something more complex, such as a wearable device with electronics or several user interfaces, then you’re talking about 6 to 12 months or even longer. This is not a rush project; it’s about accuracy, testing, and polish.

After all, you’re not simply drawing a nice thing; you’re creating something that people will actually use, maybe on a daily basis. Taking the extra time to get it right the first time will save you from expensive errors later on. In product design, patience isn’t a virtue; it’s essential to success.

Working with a design firm: Tips for a smoother ride

Want to be a dream client? Here’s how to steer clear of the bumps.

- Come with clarity. You don’t need a complete spec sheet, but have a sense of your objectives. What are you solving? Who’s your user? What’s your vision?

- Be flexible. Your idea can shift. That’s not a failure, it’s evolution.

- Provide good feedback. “I don’t like it” doesn’t tell us much. “It feels too heavy for a kid’s hand.

- Patience is polite. Respect the process. Good design is iterative. Anticipate several rounds and expect some twists along the way.

- Prototype planning. Budget and time must be allocated for not only one, but possibly several prototypes. It’s part of figuring out what works.

RELATED: What are industrial design rates & costs at product design services firms?

Design is where magic meets mechanics

There’s something thrilling about witnessing your product evolve from sketch to shelf. The best product design firm isn’t merely a team; you need to find your co-pilots on this wild journey. The process will test your patience, challenge your assumptions, and potentially reshape your initial idea through open innovation services.

But with the right partners, you’ll gain more than just a prototype. You’ll have a product ready to face the real world, with every curve, button, and detail meticulously considered by people who live and breathe design.

Cad Crowd is here to help!

So, don’t rush! Take your time to ask the tough questions and look beneath the surface. When it comes to bringing your idea to life, hiring an excellent product design team from Cad Crowd is not just the first step; it’s the most crucial one in transforming that “what if” into a “wow.” Don’t wait any longer—get in touch with us today for your free consultation and discover how we can help you turn your vision into reality! Request your FREE quote now!