Cad Crowd has years of experience working with the best furniture shop drawing services, and clients to create beautiful and functional furniture. Before we delve into the matter in question, we think it might be best to highlight the following points first:

- Shop drawings are technical diagrams of prefabricated architectural components such as millwork, casework, windows, doors, structural steel (bracing, beams, trusses, columns, etc.), MEP systems, furnishings, and custom items.

- Unlike design drawings that serve mostly as visualizations of design intent, shop drawings are the final version or the “as manufactured” schematics of those components.

- In most architectural projects, design drawings are meant to visualize how the components should look once the construction process is completed. The designer or engineer who produces the drawings is neither sourcing the parts nor specifying the pre-fabrication method; therefore, the documents might be considered preliminary plans subject to further changes.

- Shop drawings are to be produced by contractors or suppliers and then submitted to the project owner or the architect in charge of the project for approval.

In general, any component that requires off-site prefabrication or assembly–including furniture–has to come with an architect-approved shop drawing. This is to make sure that the premade components do not deviate from the on-site designs. Also, there’s no rule to prevent the contractors and interior design firms from hiring professional drafters to actually produce the shop drawings.

Although hiring a professional drafter adds another layer of communication in the approval process, having the task done by a specialized professional might actually help streamline the workflow. Drafters aren’t exactly hard to find, either. You can find hundreds, if not thousands, of them on AEC-specific freelancing platforms like Cad Crowd and the more generalized sites such as Upwork and Fiverr.

Main elements of a shop drawing

RELATED: Shop drawing rates, millwork drafting service costs & finding the right pricing for your company

Every bit of information in a shop drawing should help the manufacturer and source the right parts, procure the correct materials, and fabricate precise components to build the furniture with the right specification as intended by the designer. Accurate measurements and proper visual representation using clear schematics are crucial to ensure a perfect fit during furniture assembly. In general, a furniture shop drawing must specify the details as follows.

- Dimension: precise measurements for component fabrication, assembly, and installation.

- Materials: detailed specifications of each material, including fasteners and other parts.

- Fabrication: clear instructions on how parts and components of the furniture are fabricated.

- Connections: assembly information, especially about how individual parts interact with each other.

- Installation: straightforward guidance on securing the components or the final product in place.

- Compliance: notes to signify the design’s compliance with building codes, industry standards, and relevant regulations

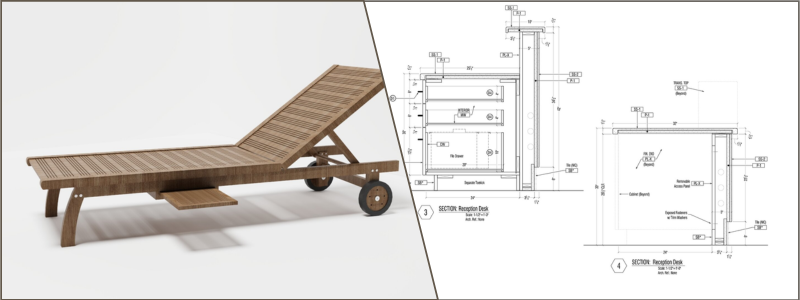

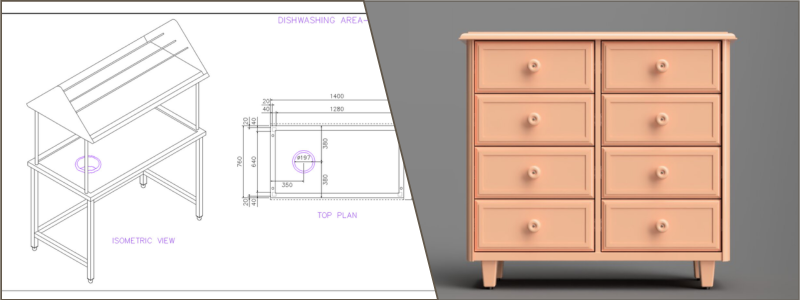

Some of those details might be listed in legends (such as materials and compliance), while the others are written as annotations directly on the illustrations. A shop drawing for a piece of furniture may include multiple schematics to provide a clear view of the design from different angles that may be provided by furniture design service partner .

Drawings for project approval

Imagine a scenario where an architect places an order with a supplier for a set of custom furniture as part of a residential project. The order comes with a bundle of design drawings, which provide a reasonably good visualization of the furniture style and overall aesthetic, but they have no detailed information about the joinery methods, types of fasteners, and hardware specifications. It doesn’t have enough details for the manufacturer to fulfill the order properly. So, the supplier hires a professional drafter to produce a more comprehensive furniture shop drawing based on the information available from the original documents. Once completed, the drawings are sent back to the architect for approval. Only when the shop drawings get the approval (maybe after a revision or two), can the furniture production begin. Note: that’s not a mere hypothetical scenario–that’s how it’s usually done in an architectural project.

Furniture shop drawings play an important role in keeping the project workflow in check. When it gets too impractical to produce furniture on the construction site, due to various reasons like safety hazards or the need for specialized equipment, the architect may opt for off-site prefabrication and assembly to keep things simple, safe, and efficient. Think of a shop drawing as the blueprint of furniture to help the contractors or suppliers present designs for the architect’s approval. And to improve the chances of getting quick approval, the shop drawings must at least cover the following functions.

Display accurate dimensions

Like every other schematic used as a construction document, shop drawings are useless if not accurate. They need to include the precise measurements of the assembled product as well as the individual parts. This is the only way that a designer or an architectiral design expert can make sure the furniture meets the original design requirement and fits into the floor plan. Because there might also be time requirements, the architect can propose design changes to speed-up completion.

Depending on the design, the interior dimension can be just as important as the exterior one. Some furniture actually need two or more drawings to highlight different sections of the design. For instance, cross-section views visualize the design as if the furniture has been horizontally or vertically cut in half. The drawing should reveal the interior parts and how they’re supposed to be assembled. Cross-section views are necessary for furniture that have multiple compartments inside, such as nightstands or cabinets.

Demonstrate structural integrity

Shop drawings are not photorealistic 3D rendering services, let alone an animated model, but it doesn’t necessarily mean they can’t visualize how the furniture works. Once again, a cross-section does a great job at highlighting the usability of the furniture. For instance, a vertical cross-section plan of a nightstand should reveal if it has hidden drawers and how to install them. If there are in fact hidden drawers, an elevation plan (front perspective) should confirm that the drawers are indeed concealed from view. Shop drawings can also use “detailed view” annotations to highlight small mechanisms or any specific components of the furniture (such as recessed lighting or door stopper) in a larger scale.

RELATED: Fabrication shop drawing services for companies: All you need to know

Make clear of the materials

Every shop drawing comes with a “material legend” to avoid confusion over why different parts of the furniture are depicted in lines of different patterns or thickness. Materials aren’t only indications of the furniture’s structural strength, but they also contribute to the aesthetic. As mentioned earlier, shop drawings are not photorealistic renderings, so it’s important to make clear annotations of the materials on every page.

The annotations serve two purposes: (1) they confirm that every component is made of the right materials in accordance with the design requirements set by the architect or designer, and (2) the annotations indicate the exact amount of materials needed to build the furniture. Although it’s nearly impossible to have zero excess when it comes to woodworking, the annotations should help the designers allocate the budget for materials more efficiently.

Be as detailed as possible

For most people, shop drawings are just as incomprehensive as blueprints and any other technical documents used in a construction project. We’d love to see 3D renderings and photorealistic visualizations of a house, furniture, interior design, or floor plan, because the technical (and two-dimensional) versions aren’t interesting enough. Mind you that shop drawings are meant to be technical instruction for manufacturing design companies to build the furniture as intended by the designers. They don’t have to be photorealistic; contractors and designers want to see detailed specifications, not an illustration of the finished product.

When it comes to shop drawings, the term “detail view” doesn’t actually refer to high resolution visualization of color shades, textured finishes or something like that, but zoomed-in view of the otherwise small groups of components positioned closely together. For example, a detail shop drawing of a cabinet shows how multiple layers of different materials are stacked together in the corner section, where to insert the fasteners, how the door mechanism works, and so forth. Not every section of the furniture needs a detail view, but it doesn’t hurt to include as many as reasonably practicable.

RELATED: 4 tips to improve cabinet shop drawings for manufacturing efficiency at companies

Best practices

A shop drawing is also supposed to function as a communication tool, so make sure you include all the necessary information and be mindful about the formatting. The main objectives are accuracy and readability. Sticking to these best practices helps minimize mistakes.

- Emphasize clarity: The whole idea of a shop drawing is to draft a two-dimensional instruction schematic for an off-site prefabrication of furniture. There’s no need to be overly creative about it. Similar to just about every assembly schematic out there, a shop drawing must be heavily annotated with labels and legends. Some shop drawings use color coding to improve readability and avoid misrepresentation, while others use various line patterns and weights to highlight different construction components and parts. Don’t overcrowd the page with too many drawings; use as many sheets as necessary to maintain clarity.

- Use CAD software: Manual drawing with pencils and rulers probably still has its place in the modern world, but unless it’s absolutely necessary (which most likely isn’t), be kind to yourself and use CAD software instead. Computerized drawing is quicker and more consistent for design and drafting companies. Most software packages include a vast array of automation tools and customization options. For example, the Cabinet Vision by Vero Software can automatically update the manufacturing operation of cabinetry based on design changes; another popular option is Microvellum, thanks to its parametric modeling and automated drawing.

- Coordinate with the team: In case the design intent is unclear or ambiguous in some way, always seek clarification before you even start drawing. Actually, the use of CAD software makes it easier for you to share the work-in-progress with other members of the team for reviews. Having the work checked by fresh eyes can help catch errors early on.

- Adhere to standards: Every industry and trade has a set of standards. In the case of furniture shop drawing, there are recognized standards such as ANSI and ISO for dimensioning, layout, the use of symbols, and tolerancing. The annotations also need to reference known standards like AWI for architectural woodwork. It has to specify the materials (types and grades), thickness, finishes, and other components using relevant standard codes or symbols. The same rule applies to parts and components with performance requirements, such as fire resistance rating, load-bearing capacity, acoustic performance, water resistance, etc.

Speaking of compliance and adherence to standards, especially for critical components, the shop drawing might need a stamp by a qualified engineer to signify that the design complies with the relevant engineering principles and local codes. If the shop drawing is a revision due to design changes or any kind of data errors, it all has to be clearly documented with dates and revision number.

Typical concerns in the shop drawing process

The whole idea behind a shop drawing is to streamline furniture design and production for an architectural project, but there can be some issues–unexpected or otherwise–in the drafting process that slow down progress. Among the most common issues actually is error in the initial design drawing. Any miscalculation in the original image can carry over to the shop drawing.

For instance, inaccurate dimensions of a furniture part can result in components that just won’t fit the intended place. It might not be much of a problem if the exact spot is spacious enough to give some elbow room, but if it’s tight with little width and height tolerance, the final furniture will look out of place. In some cases, it can’t even be installed correctly. An effective way to mitigate the issue is to verify the design drawing first with the architect or designer, or to take it to the next level, hire a 3D furniture modeling service to help you visualize. A field inspection is ideal, but it’s only possible if the structural components (walls, ceiling, electrical outlets, fixtures, etc.) are already constructed.

Another possible issue is poor communication between manufacturer and designer. Lack of coordination may lead to inconsistent shop drawings. For instance, a manufacturer uses an old version of a design intent only because the designer forgets to send a notification about the matter. It’s also possible that the supplier mistakenly procures incorrect materials because no one bothers to verify the order.

Ineffective communication with the team also leads to approval delays. Furniture manufacturing, as simple as it seems, involves a lot of people–each is responsible for a specific task that affects another. Approval delay happens when any of the stakeholders, such as the designer or client, is unable to review the shop drawing on time. It might sound like a trivial setback, but the effect can ripple through the scheduled timeline. To mitigate the issue, it’s best to use a centralized system that can facilitate proper collaboration. It doesn’t even have to be a fancy premium SaaS platform or anything like that; a simple cloud storage solution with real-time update and reminder should do the job just fine.

Despite the challenges, furniture shop drawings remain an effective way to present designs to architects for project approval. Shop drawings are often based on the design intent (by the project architects or designers) before it’s transformed into heavily annotated schematics (by the contractors or furniture manufacturers/suppliers). The resulting documents are meant to showcase the expected shape, dimension, materials, internal mechanisms, assembly process, and structural integrity of the furniture. You can say that shop drawings are tools used by a contractor to convince an interior design experts to give the green-light to proceed with the prefabrication and assembly processes. To improve the chances of success, the contractor first has to make sure that the shop drawings meet the desired quality and are comprehensive enough to represent the original design intent.

Conclusion

Not every single furniture must be fabricated and assembled on the construction site. Perhaps the furniture is a custom design, which requires specialized fabrication method and tooling in an off-site facility; maybe the architect wants to make sure that the construction site has minimum distraction, so off-site prefabrication is preferable. No matter the reason, it shouldn’t be a problem as long as the architect still maintains complete control over every single detail, including the materials, the part, the finishes, the lot. This is why every single prefabricated piece of furniture must come with a shop drawing reviewed and approved by the architect.

More than just schematics of a product, the shop drawing is a communication tool between the supplier, contractor, consulting engineer, the architect, and the project owner. It makes sure that everybody is on the same page before production, reducing the likelihood of incorrect specification and preventing expensive rework. Shop drawing is the blueprint of a furniture, and you want it produced by a professional to minimize the risk of misrepresentation and inaccuracies. The good thing is that most architectural drafters in this day and age, including those you may find freelancing sites like Cad Crowd, have a good understanding of the furniture manufacturing process and excel at CAD software to produce accurate and comprehensive shop drawings.