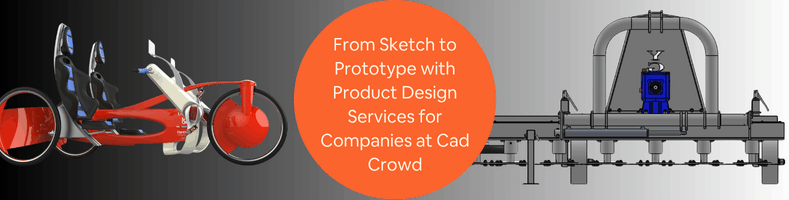

Within today’s competitive business climate, a new product journey from concept to reality is made possible with speed, precision, and collaboration. Product design service sits at the core of such an operation to enable firms to have a hazy sketch transformed into a usable prototype that is ready to produce.

Cad Crowd, the leader in on-demand CAD services with over 94,000 experts, supports companies in this intricate process by providing expert guidance at every stage. The website connects companies with the cream of the crop when it comes to product design services that can help with every stage of the process, from creating sketches to generating prototypes.

🚀 Table of contents

- The role of product design sketches in development

- Why does product design matter in product development?

- Improving sustainability and longevity

- The role of CAD in product design

- From CAD to rapid prototyping: The next stage

- Iterative design: Prototyping refinement

- Manufacturing readiness: On the way to production

- Why choose Cad Crowd for product design services?

- The future of CAD in designing and manufacturing

- Conclusion

- Cad Crowd is here to help

The role of product design sketches in development

The journey of any product begins with a concept, often a rough drawing. These sketches are not aesthetic images but essential conceptualization and communication tools for product vision. Well-drafted design sketches are the foundation of CAD modeling, which facilitates enhanced visualization and decision-making.

An exact sketch helps the designers and engineers understand the product’s basic functioning and appearance before spending resources on development. It also helps identify potential design faults early, saving time and costs. In the majority of industries, like this one here, such first sketches undergo multiple drafts before entering the next development phase, verifying that all facets of the design are compatible with market demands as well as manufacturing feasibility.

RELATED: Key factors to consider when vetting engineering firms for design & consulting services

Why does product design matter in product development?

On the aesthetics aside, in the world of product development services, design is a determinant of success or failure. Product design impacts user experience, manufacturing efficiency, and ultimately, business growth and customer satisfaction. Organizations that appreciate thoughtful design can reap significantly more than organizations that consider design an afterthought. The reasons why product design is essential in every stage of development are listed below.

Enhancing user experience

Great product design begins with the user. A well-designed product is intuitive, functional, and enjoyable to use. Consumers today expect seamless experiences, and a bit of friction in the form of a complex interface, clumsy grip, or hard assembly is sufficient to generate frustration and abandonment. The best designs anticipate needs and resolve pain points in advance. For example, manufacturers of phones invest a lot of money in ergonomics, so that their phones will be comfortable to hold in the hands of their customers while being thin. If design is usability-focused, then customer satisfaction is guaranteed to follow.

Differentiating in a crowded market

In any industry, competition is fierce. A well-designed product becomes iconic and accumulates brand reputation. From the elegance of an Apple product to the ruggedness of a Jeep, a design imposes a company’s values and identity. A creative, unique design can be the sole reason a customer uses one brand over another. Organizations that regularly revise their designs are capable of staying in line with current times and adapting to changing market trends.

Enhancing functionality and performance

Design isn’t just about appearance—it’s a problem-solving activity that optimizes functionality. Designers and engineers collaborate to refine form and function so that the product carries out its desired function with optimal efficiency. This applies to everything from consumer electronics to industrial machinery. Poor design can lead to performance issues, increased failure rates, or customer dissatisfaction. By integrating design thinking at the outset of development, companies can reduce costly redesigns and improve product reliability.

Decreasing manufacturing costs and complexity

An intelligent design not only enhances usability but also impacts manufacturing viability, which is critical. Design for manufacturability (DFM) services ensure a product can be manufactured at reasonable costs without having additional costs or time for production. Simple but efficient design choices—such as simplifying the number of components, employing easily procurable materials, and simplifying assembly in the design—save significant costs in production. Optimizing design for manufacturing in organizations gives them a competitive advantage through cost reduction without sacrificing quality.

Improving sustainability and longevity

Sustainable design is increasingly a primary concern in modern product development. Consumers and businesses alike are more eco-aware, and the more sustainable the product, the more desirable it is. Thoughtfully made design choices—like recyclable material, low energy consumption, and longevity—assist in giving a cleaner lifecycle. Products with longer lifespans and less waste assist in building consumer trust and contribute to growing global efforts toward sustainability.

Product design is not merely about making something look good—it’s a strategic element that affects user experience, marketability, efficiency, cost, and sustainability. Investing in great design upfront in the product development process ensures that products perform better, stand out in the marketplace, and create enduring value. In an increasingly competitive world, companies that understand the power of design will always be ahead.

RELATED: 10 design principles for product development & industrial design services teams

CAD modeling: Bridging the gap between concept and functionality

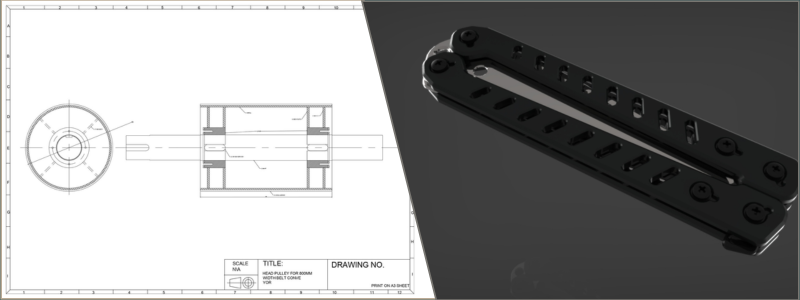

Concept to reality is a vital process in today’s product development and engineering. While hand sketches and conceptual drawings play a significant role during the initial design stages, they are not practical and precise enough for production purposes. That’s where CAD (Computer-Aided Design) modeling fits in, serving as the bridge between raw concepts and functional products. CAD modeling design services translate raw concepts into highly accurate digital 3D models, enabling designers and engineers to fine-tune every aspect of a design before a single physical prototype is made.

As businesses rely increasingly on technology-based solutions, CAD has become a critical part of product design, architecture, mechanical engineering, and fashion. Its allowance for accurate visualization, structural evaluation, and effortless collaboration makes it inevitable. Business entities like Cad Crowd bring together companies with expert CAD designers in a bid to achieve high-end models that appeal both aesthetically as well as functionally.

The role of CAD in product design

CAD modeling is not just an exercise in coming up with a nice-looking picture; it’s optimizing and maximizing designs for performance, manufacturability, and efficiency. Let’s talk about the leading advantages CAD can provide in product design.

Increased accuracy

Accuracy is the key to successful product design. CAD software allows designers to employ accurate measurements, so that each component will assemble perfectly in an assembly. Compared to manual drafting methods, where human error is a common occurrence, CAD software minimizes errors by employing automated dimensioning, geometric constraints, and parametric modeling. Engineers can design with tight tolerances, so that all parts will function as intended when produced.

For instance, in the automobile industry, a millimeter or two may be the difference between success and failure. CAD enables product development experts to mold tiny details so that engine components, gears, and chassis components can be assembled together smoothly. Such accuracy not only makes products more functional but also reduces the likelihood of costly design flaws.

Cost and time efficiency

One of the most powerful advantages of CAD modeling is its ability to shorten product development time. Traditionally, physical prototyping and design were an expensive and time-guzzling task. CAD helps engineers create computer-based prototypes that can be easily modified within a short span of time, saving the hassle of repeated physical runs. This generates huge cost savings by eliminating wastage of materials and labor expenditures for repeated running of prototypes.

Additionally, CAD software minimizes the design process by offering pre-made components, automated functions, and standard part libraries. This allows the designer to focus on creativity rather than repetition. Moreover, CAD functions well with CNC machining and 3D printing technology, allowing for rapid prototyping and efficient manufacturing processes.

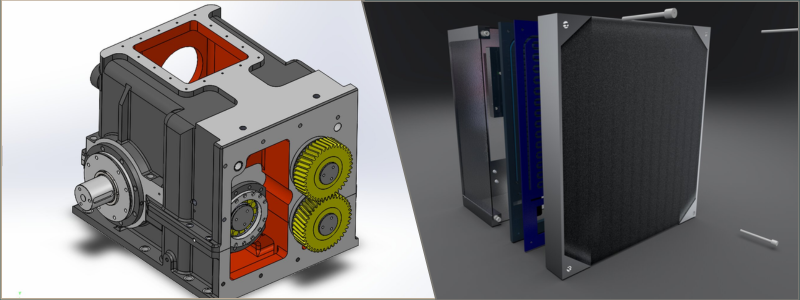

Design optimization and performance testing

Aside from graphic presentation, CAD enables engineering design firms to optimize and analyze their designs. By means of simulation and analysis features embedded within the software, designers can test structural strength, stress patterns, aerodynamics, and material response to varying conditions.

For example, in the aviation industry, CAD is used to simulate air drag, heat, and mechanical stress on aircraft components before they are manufactured. Predictive analysis like this alerts engineers to potential weak points early in the design process, allowing them to reinforce critical points without over-engineering the structure. This way, companies can create light, strong, and high-performance products at no additional cost.

Additionally, CAD facilitates material selection via the potential of designers to compare materials virtually. With the analysis of weight, strength, flexibility, and cost, companies can make a decision prior to committing to a specific material for manufacturing.

Smooth collaboration across teams

Product design is rarely a one-person job. Various stakeholders, like engineers, designers, manufacturing design experts, and clients, must sit together to deliver a successful project. CAD software allows collaboration by providing a shared digital platform on which all stakeholders can see, edit, and approve designs in real-time.

Cloud-based CAD tools also improve collaboration by providing remote access to design files, making it possible for global teams to collaborate effectively. CAD software also accommodates multiple file formats, which makes it compatible with a variety of manufacturing and engineering tools. CAD modeling eliminates miscommunication and version control problems, making everyone on the same page during the design and production process.

RELATED: Master product design costing: Top strategies for CAD services companies & freelance designers

From idea to reality: A digital revolution

The ability to visualize through complex geometries, model real-world constraints, and explore various manufacturing methods in a virtual environment has revolutionized product development. Compared to traditional methods that rely on trial and error, CAD-based design is data-driven, precise, and effective.

Every industry, from consumer electronics design services to industrial machinery, depends on CAD modeling to upgrade their products prior to mass production. Consider the smartphone industry: every new model is subjected to a comprehensive digital simulation prior to landing on shelves. Engineers use CAD software to study drop tests, heat dissipation, and ergonomics to create a great-looking, durable final product.

Likewise, in architectural construction, CAD modeling allows builders to draft accurate building blueprints, from structural elements to plumbing, electrical schematics, and aesthetic details. Architects are able to design entire skyscrapers, simulate daylight effects, and perform energy-efficiency tests—all before the first brick is set.

From CAD to rapid prototyping: The next stage

CAD models are the basis for rapid prototyping, or creating a physical representation of the design. Companies on Cad Crowd have access to advanced prototyping techniques, including:

- 3D printing: Best suited for quick iteration and experimentation with multiple materials.

- CNC machining: Provides high precision for functional prototypes.

- Injection molding: Ideal for testing mass-production feasibility.

- Vacuum casting: Convenient for creating accurate, durable prototypes.

Prototype engineering services facilitate real-world testing, such that the product is industry-grade and performs as expected. Refining and tweaking can be effectively achieved before mass production.

Iterative design: Prototyping refinement

Prototyping is rarely a one-step activity. Companies prefer to go through multiple iterations to improve functionality, appearance, and manufacturability. Cad Crowd’s platform facilitates companies to work with seasoned engineers who refine designs on the basis of:

- User feedback: Gathering feedback from potential end-users for the simplicity of use.

- Material testing: Verification of chosen material against performance and longevity.

- Ergonomics & aesthetics: Balancing usability and visual appeal.

- Manufacturing constraints: Design in accordance with production at the lowest costs.

Iterative prototyping and refinement maximize business potential in the market at a lower risk of expensive post-launch redesign.

Manufacturing readiness: On the way to production

Following verification of a prototype, the next step is gearing up for large-scale production. CAD services play a pivotal part in enabling economic production by designing:

- Top-level engineering drawings: Step-by-step guides that guide manufacturers during mass production.

- Bill of Materials (BOM): A bill of materials listing.

- Assembly instructions: Sequential instructions for factory workers.

- Tolerancing and GD&T analysis: Ensuring mechanical fit and performance.

Cad Crowd helps companies transition seamlessly from prototype to production with highly detailed CAD files that are optimized for various manufacturing processes.

Why choose Cad Crowd for product design services?

Cad Crowd offers businesses access to a worldwide pool of talented designers, engineers, and prototyping experts, allowing businesses of any size to effectively create and improve their products. Through Cad Crowd, clients enjoy a number of important benefits:

- On-demand expertise: Regardless of whether your project needs CAD drafting, mechanical engineering, or industrial design experts, Cad Crowd provides you with pre-screened experts specializing in different sectors. No more headaches of recruiting full-time employees.

- Cost-effective solutions: The platform provides flexible pricing models that adjust according to your individual project requirements, facilitating startups and existing businesses in controlling their expenses while procuring elite talent.

- Fast time-to-market: Cad Crowd quickens the process of design, delivering rapid iteration and rapid prototyping, thereby ensuring that your product hits the market in a minimum amount of time.

- IP protection: Privacy is paramount, and Cad Crowd makes sure all intellectual property is treated with utmost confidentiality, ensuring your designs don’t fall into the wrong hands.

From initial ideas to production-ready products, Cad Crowd offers the support and skills necessary to take ideas into marketable solutions, thus becoming a reliable partner for businesses looking for efficiency and innovation.

RELATED: How to improve product development for your company with engineering firms & design consultants

The future of CAD in designing and manufacturing

As technology progresses, so does the role of CAD in product design. Artificial intelligence (AI) and machine learning incorporated in CAD software see automation further augmented, allowing designers to generate optimized models with minimal human input. AI-driven generative design is already used in industries like aerospace engineering services and automotive manufacturing, where program algorithms propose design alternatives based on performance specifications input by users.

Additionally, CAD is increasingly collaborating with Virtual Reality (VR) and Augmented Reality (AR) technologies. These innovations enable engineers to interact with their designs virtually, allowing for enhanced spatial understanding and real-time modification.

As Industry 4.0 and smart manufacturing take hold, CAD also plays a big role in digital twin technology. Digital twins are computer simulations of physical products or systems employed to track in real-time, conduct predictive maintenance, and analyze performance. The technology is transforming industries like healthcare, with CAD-generated digital twins of medical devices and prosthetics making personalized patient solutions possible.

Conclusion

CAD modeling is now the backbone of modern product design as a pivotal bridge between conceptual sketching and practical reality. As a powerful tool that can provide more precision, cost savings, design optimization, and seamless collaboration, CAD empowers designers and engineers to break new ground.

From architecture to industrial design services, consumer goods, or industrial manufacturing, CAD software ensures end products are not only aesthetically sound but also functionally sound and production-ready. With the progress being made with AI, simulation, and digitization, CAD modeling will remain a core asset in shaping the destiny of design and engineering.

For businesses looking to leverage the potential of CAD, working with seasoned experts through platforms like Cad Crowd ensures access to top-notch designers who can bring ideas to life quickly and precisely. As businesses embrace digitalization, CAD modeling continues to be the backbone of intelligent, high-performance product design.

RELATED: 10 key costs for electronic pdesign & drates for engineering services companies

Cad Crowd is here to help

From sketch to prototype, product creation is a high-tech but rewarding process that calls for technical expertise and strategic vision. With Cad Crowd’s comprehensive product design solutions, companies can lead every step with confidence, from sketching and CAD modeling all the way through to prototyping and manufacturing.

In a world where speed, quality, and innovation decide market success, collaboration with a trustworthy CAD services provider ensures that your product development process remains on track, competitive, and future-ready. Be it a cutting-edge consumer device or an industrial part, Cad Crowd is a trusted partner in bringing your vision to life.

Feel free to contact us today to order a quote for our product design services and beyond!