Locking Mechanism Design for Consumer Product Blind

in

3D Modeling Design

held by

lkharr

Last seen:

Contest Ended, Winner(s) have been selected.

-

Open

-

Choosing Finalist

-

Ended

Description:

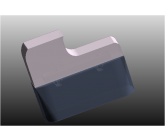

We are looking for a locking mechanism for our upcoming product that is simple and minimalistic, yet very robust in how it locks the two pieces together. When locked there will be lateral stresses forcing the pieces to slide apart. We want there to be virtually no chance of the pieces coming apart by accident while locked, and the mechanism must be simple and intuitive. Items that must reamin the same are the length and width of the objects. Enjoy full freedom to change the trapizod shape.

Please refer to attached images for some of our previous ideas. These are simplistic, but they are either not aestheticly pleasing or they do not provide a reliable lock while the product is in use.

We have uploaded 4 different file types because we wern't sure what your preference would be. Please also take a look at the attached images to see the other mecanisms that we have designed thus far. These are the ones that we like for simplicity and minimalism sake but they are not the most effective or intuitive.

Wants:

Simplicity, minimalism, effectiveness of lock, intuitive design

Don't Wants:

Ideally, the mechanism would be internal or along the long edge of the pieces. We are not looking for something with various other pieces that will be needed to be manufactured.

Software:

- Autodesk Fusion 360

Entries

1st Winner

#22 VERSION 3

by RBLdesign

Download Files

#16 version 2

by RBLdesign

#3 Catch1

by DesignAssist

#15 Final Concept

by DesignAssist

#10 locking mechanism

by RBLdesign

Download Files

#7 Modified Concept

by DesignAssist

Download Files

#2 Snap Lock

by kspeedy28

Download Files

#9 Locking mechanism

by MR. CAD DESIGNS

#1 Press and Twist

by Duncan SmartEng

#5 Aérospace inspired hidden lock mechanism

by BuzzBen

Download Files

#14 Locking Mechanism Design for Consumer Product

by Ratnesh_kumar

Download Files

#4 Link System Concept showing use of Military Standards application

by BuzzBen

Download Files

#39 Locking Mechanism

by unocuatro

#28 Slide Lock revision

by kspeedy28

Download Files

#29 Locking Mechanism Design for Consumer Product

by edward m barnes

#27 locking_mechanism_consumer_product_concept-3.stp

by Karthikeyan Arumugam

#30 Locking Mechanism curve

by Oliver Marcano

Download Files

#31 Lucking Mechanism Design - by Adriano Ordoz Barissa

by Adriano Ordoz Barissa

#33 Locking Mechanism

by Mahbub

Download Files

#34 Locking Mechanism

by Straightedge

Download Files

#35 locking mechanism 3

by MR. CAD DESIGNS

Download Files

#36 Locking Mechanism Diagonal

by Oliver Marcano

Download Files

#37 1512938918CAD_Crowd_v2

by Yohanes Ujang

#26 More intuitive - I submitted the locking mechanism

by Saif

Download Files

#25 plus design ideas

by Saif

Download Files

#24 2nd design - please see all my designs-

by Saif

Download Files

#23 1st design -see all my designs please-

by Saif

Download Files

#21 LOCKING MECHANISM 2

by MR. CAD DESIGNS

#20 Locking mechanism by injected molded part

by MSABOUBH

#19 snap on lock

by ferrabi

Download Files

#18 Locking Mechanism Design for Consumer Product

by sherifelsheikh

Download Files

#17 Locking1

by ferrabi

Download Files

#13 PB model 1

by Artspace

Download Files

#12 locking_mechanism_consumer_product_concept-2.stp

by Karthikeyan Arumugam

#11 locking_mechanism_consumer_product_concept-1.stp

by Karthikeyan Arumugam

#8 locking_mechanism_consumer_product_concept-1.stp

by Karthikeyan Arumugam

#6 Locking mechanism type A and type B

by Artspace

Discussion

Howdy, Everyone! We would like to thank each of y'all for your work in helping us to design the best possible locking mechanism for our product! There were some incredible designs that really were innovative, minimalistic, and simplistic. We would like to congratulate RBL Designs on being chosen as the winner and for his help along the way!

Thanks again and be on the lookout for future contests from us!

Landon and John

1310 Ventures

Thanks again and be on the lookout for future contests from us!

Landon and John

1310 Ventures

So you want to design an attaching system to join different brush heads to a common handle. Also could you please tell if the brush+handle device will be manually operated or by a machine. Also tell what are you going to apply with the brush, whether a powder/oil/paint etc. Thank you.

you left a space between the handle and your locking mechanism

must this area be free?

must this area be free?

Yes The pieces will need to be locked and unlocked multiple times per day

Yes it will be injection molded

Is it plastic injected part?

does it have a lot of going in and out?

or you want to make the part in its place for a long time or for product life

or you want to make the part in its place for a long time or for product life

How does the head detach once it's been Locked?

How does the head detach once it's been Locked?

Howdy guys,

So we do not have a hard number or unit for the force applied that it needs to withstand. With that being said, this is a paint brush head, so think of the force that is applied to a paintbrush while you are holding it at an angle. We want it to obviously be able to withstand that force with possibly a safety factor of around 3 or 4, just to ensure that there is no possible way whatsoever that the brush will accidentally pop out of place while painting. Please let us know if you have any other questions. Thanks!

So we do not have a hard number or unit for the force applied that it needs to withstand. With that being said, this is a paint brush head, so think of the force that is applied to a paintbrush while you are holding it at an angle. We want it to obviously be able to withstand that force with possibly a safety factor of around 3 or 4, just to ensure that there is no possible way whatsoever that the brush will accidentally pop out of place while painting. Please let us know if you have any other questions. Thanks!

It would also be most helpful to attach a basic sketch of the forces directions. There are to be 2 things to consider, the force required to attach and disconnect the 2 pieces together, but also the eventual force or stress when using the assembled tool. We can design an attachment that fits the first set of force but that might not be appropriate for the second set of forces/stress when the tool is being used. We also need that to consider mechanical clearance between the 2 parts. Thanks.

It would be really helpful if you attached a similar product to the one you want. just so we don't get lost.

Howdy All,

The product is a painting tool and will be made of injection molded plastic, so the forces shouldn't be that great. Honestly, I'm not completely sure what they'll be, but lets just say that its somewhere around 5-7 pounds at its maximin that will be trying to force the pieces apart.I'm working on verifying payment. Sorry for the holdup on that.

Thanks!

The product is a painting tool and will be made of injection molded plastic, so the forces shouldn't be that great. Honestly, I'm not completely sure what they'll be, but lets just say that its somewhere around 5-7 pounds at its maximin that will be trying to force the pieces apart.I'm working on verifying payment. Sorry for the holdup on that.

Thanks!

But, as optibild said we need its application and forces involved to solve it better.

Cool project. I will participate.

What is the force applied in the lock position that could cause this lock to open unexpectedly?

Please make the contest prepaid hence will intend to give you right and best solution ...

verify payment.

Similar Contests on Cad Crowd

SuperSuv to be hand built for personal use

Off/On Road Super SUV, 3 seater Central driving position like a Mclaren. Rear engined, removable roof which when not in use goes over engine bay. 26 inch rims. Very clean lines. Will use donor lights (pictures included in files). Car must be dramatic with very clean simple lines. Interior must be very simple and clean lines.

I have uploaded many files for inspiration. Countach for rear. Corvette for door treatment. White lotus for air vents. Diablo for roof and body lines.

Jowalla Konnekt

we are looking to design a casing that will hold a BLE chip and NFC tag the product will be adhered to or clamped onto the likes of entrances to malls, bus stops , inside of taxi cabs, on board trains and buses and adhered to ATM machines.

3D Modeling and Roof Design

I would like an exterior and roof designed based on my floor plans. Project MUST be done in Chief Architect. Looking for a modern style home, shed roofs, similar to the contemporary home on our website http://www.inartifex.com/#!untitled/zoom/cqxa/image1ido

Material can be a mix of stucco, board and batten, limit the use of stone as the home is budget conscious.

Feel free to be creative. You do not need to use the existing material etc.

KLEIN 2-Way Radio

This is a small desktop 2-way radio. Instead of having it on your hip, or a big bulky dispatch radio, this is the size of a portable radio in a desktop box.

Bas Relief Panels

Create bas relief panel models to be CNC routed from MDF sheet. I will provide exact panel dimensions, sketches of the design and images to be modeled. Photos of similar examples attached.

Prepaid Prize

Prepaid Prize

lkharr

Buyer