arcylic box

in

3D Modeling Design

held by

keenlycheerylicence

Last seen:

Contest Closed

-

Open

-

Choosing Finalist

-

Ended

Description:

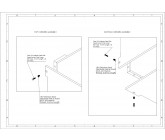

End product is a flat pack clear (acrylic box) - without one side.5 clear plastic sheets snap together to make a box without any tools and for it to be fairly easy to assemble and dismantle but when assembled for it to remain sturdy.

Thickness of plastic sheet 3mm+

L50cm x H50cm x W50cm for box approx

Wants:

design of locking the sheets together, and how they dismantle.

Don't Wants:

The sheets need to be as flush as possible with the least amount of material protruding.

Ask for Sample:

I want samples

Software:

- SolidWorks (2)

Entries

#6 Acrylix boX

by Donis

Download Files

#5 Enclosure

by MonilSolanki

Download Files

#4 perfect clear box

by franznoise

Download Files

#3 perfect clear box

by franznoise

Download Files

#2 BOX

by Marco B

Download Files

#1 arcylic box

by REDA

Download Files

Discussion

Showing last 20 comments - View All

Hi all,

I hope buyer prepaid this contest and announce the winner soon.

If this contest still pending without winner, Cad Crowd must do something to prevent it happen for upcoming contest.

Buyer must be professional and respect all designer effort.

Good luck to all.

Regards,

BRAVO

I hope buyer prepaid this contest and announce the winner soon.

If this contest still pending without winner, Cad Crowd must do something to prevent it happen for upcoming contest.

Buyer must be professional and respect all designer effort.

Good luck to all.

Regards,

BRAVO

Hi Jay Singh,

Yesterday I have uploaded my modified design. The number is 55. Have you checked it?

Regards,

Rupak B.

Yesterday I have uploaded my modified design. The number is 55. Have you checked it?

Regards,

Rupak B.

To solve your problem, May i Know the purpose of use to 12 year kids

dear jay sighn,

can you open my drawing?

thanks

can you open my drawing?

thanks

Hi Jay Singh,

Could you please fuelling us (Designers) a little, by removing the condition “Payment Pending”?

Could you please fuelling us (Designers) a little, by removing the condition “Payment Pending”?

Hi,

after all these Entries , is still pending here ... has

after all these Entries , is still pending here ... has

27 is the number

@ Jay - Have you checked the design I reposted,  ?

?

Does it fulfill your requirements?

?

?Does it fulfill your requirements?

@ Jay Singh,

Yes, you are right. Sorry for taking time. Actually I am preparing a revised design by eliminating all sorts of negative possibilities, which is requiring a thorough analysis.

However, I will return to you as soon as possible with a best design.

Regards,

Rupak B.

Yes, you are right. Sorry for taking time. Actually I am preparing a revised design by eliminating all sorts of negative possibilities, which is requiring a thorough analysis.

However, I will return to you as soon as possible with a best design.

Regards,

Rupak B.

@ Rupak B - It& ;s great idea but the 5 sides aren&

;s great idea but the 5 sides aren& ;t truly flat pack they have a wide footprint or surface area rather than being able to stack ontop of each other - they must come 100% apart for upgradeability too. We await your new designs.

;t truly flat pack they have a wide footprint or surface area rather than being able to stack ontop of each other - they must come 100% apart for upgradeability too. We await your new designs.

@joshhubbuch - Yes but its going to be costly + heavy so whatever design you do will score less due to this.

;s great idea but the 5 sides aren&

;s great idea but the 5 sides aren& ;t truly flat pack they have a wide footprint or surface area rather than being able to stack ontop of each other - they must come 100% apart for upgradeability too. We await your new designs.

;t truly flat pack they have a wide footprint or surface area rather than being able to stack ontop of each other - they must come 100% apart for upgradeability too. We await your new designs.@joshhubbuch - Yes but its going to be costly + heavy so whatever design you do will score less due to this.

Is one centimeter thick acceptable??

Dear Jay,

Thanks for your opinion.

But the hamster will not get access to the zipper by any means. It is because, the zippers are completely at outside of the box and when the sides are closed by a zipper, the inner edge of each side will completely pressed each other to make the box rigid in assembling condition. Only we have to paste the zipper on the outside of box edge, in such a way, so that, it will completely pressed each other side when the zipper will close.

So, you can think over it further, and in the meanwhile I am also trying to develop further better solution for the above said box.

Regards,

RB

Thanks for your opinion.

But the hamster will not get access to the zipper by any means. It is because, the zippers are completely at outside of the box and when the sides are closed by a zipper, the inner edge of each side will completely pressed each other to make the box rigid in assembling condition. Only we have to paste the zipper on the outside of box edge, in such a way, so that, it will completely pressed each other side when the zipper will close.

So, you can think over it further, and in the meanwhile I am also trying to develop further better solution for the above said box.

Regards,

RB

I like the idea but the gap(zip) between the each sheet will be chewed by the hamster.

I like the idea but the gap(zip) between the each sheet will be chewed by the hamster.

@CS ok waiting - @Yontash I really don& ;t mind as long as manufacture can read but solidworks preffered.

;t mind as long as manufacture can read but solidworks preffered.

@Reda please read all the description + comments. The box can& ;t have anything on the outside - needs to 100% flush.

;t have anything on the outside - needs to 100% flush.

That&

That& ;s a great fiting but can&

;s a great fiting but can& ;t see how it fixes to the bottom - concerned about it coming out - when slided out and moved.

;t see how it fixes to the bottom - concerned about it coming out - when slided out and moved.

Great interlocking system will it hold without any screws - need technical drawing ot see how thin/thick things are becoming, but really good, I think this could work but I think we need to go up 6-8mm per sheet due to the thin cuts.

Great interlocking system will it hold without any screws - need technical drawing ot see how thin/thick things are becoming, but really good, I think this could work but I think we need to go up 6-8mm per sheet due to the thin cuts.

Nothing can be protroding needs to be 100% flush -please read description + comments

Nothing can be protroding needs to be 100% flush -please read description + comments

I like the concept but same as 27

I like the concept but same as 27

;t mind as long as manufacture can read but solidworks preffered.

;t mind as long as manufacture can read but solidworks preffered. @Reda please read all the description + comments. The box can&

;t have anything on the outside - needs to 100% flush.

;t have anything on the outside - needs to 100% flush. That&

That& ;s a great fiting but can&

;s a great fiting but can& ;t see how it fixes to the bottom - concerned about it coming out - when slided out and moved.

;t see how it fixes to the bottom - concerned about it coming out - when slided out and moved. Great interlocking system will it hold without any screws - need technical drawing ot see how thin/thick things are becoming, but really good, I think this could work but I think we need to go up 6-8mm per sheet due to the thin cuts.

Great interlocking system will it hold without any screws - need technical drawing ot see how thin/thick things are becoming, but really good, I think this could work but I think we need to go up 6-8mm per sheet due to the thin cuts. Nothing can be protroding needs to be 100% flush -please read description + comments

Nothing can be protroding needs to be 100% flush -please read description + comments I like the concept but same as 27

I like the concept but same as 27

Hi jay singh,

I do not understand you want screws or other elements that take? or self-snap?Please ..

we explain what is not clear

Thanks

REDA

I do not understand you want screws or other elements that take? or self-snap?Please ..

we explain what is not clear

Thanks

REDA

You only want the designs in Solidworks? Not Autodesk Inventor?

Hi Jay,

I am working on it. It can be made sleek and user friendly.

Regards,

Chintan

I am working on it. It can be made sleek and user friendly.

Regards,

Chintan

the tabs need to be inside rather than outside and then a countersunk hole ofsetted. Can sheets be moulded like this or bent rather than glued - I&

the tabs need to be inside rather than outside and then a countersunk hole ofsetted. Can sheets be moulded like this or bent rather than glued - I& ;m trying to keep optical clarity 100% - glueing PMMA will make that section blurry. Great idea though just need weight out cost.

;m trying to keep optical clarity 100% - glueing PMMA will make that section blurry. Great idea though just need weight out cost.@adam I agree with 3mm thickness is too thin I was thinking of bending the sheet somehow the way sheet metal is and somehow fixing.

Like I said we can go upto 10mm but remember a 12 year old girl or even younger is going to open and assemble this - we are trying to make it that easy but keeping in mind weight + cost of each process, we save in shipping + storage.

what happened to the 3mm thickness specification. you& ;re not going to get anything that snap together in this large of a sheet size that is structurally sound.

;re not going to get anything that snap together in this large of a sheet size that is structurally sound.

;re not going to get anything that snap together in this large of a sheet size that is structurally sound.

;re not going to get anything that snap together in this large of a sheet size that is structurally sound.

Hi Jay Singh,

To be confirmed, what is mean by 5 clear plastic sheets snap together to make a box "without any tools"? Is screw accepted? Sorry but I just confuse by your description of without any tools.

Thanks

@bravo screws are accepted i want to change the description I doesn& ;t let me so. Screws, pins other fasterns are accepted was thinking even metal cam system one turn and its locked but you need to understand these fixtures aren&

;t let me so. Screws, pins other fasterns are accepted was thinking even metal cam system one turn and its locked but you need to understand these fixtures aren& ;t usually used in sheet platic plus you need to make the thickness of the sheet 6-10mm which is ok but thinner the better not too thin but 6mm is about right. We dont mind going up to 10mm but doing so needs to solve the problem in the best way.

;t usually used in sheet platic plus you need to make the thickness of the sheet 6-10mm which is ok but thinner the better not too thin but 6mm is about right. We dont mind going up to 10mm but doing so needs to solve the problem in the best way.

To be confirmed, what is mean by 5 clear plastic sheets snap together to make a box "without any tools"? Is screw accepted? Sorry but I just confuse by your description of without any tools.

Thanks

@bravo screws are accepted i want to change the description I doesn&

;t let me so. Screws, pins other fasterns are accepted was thinking even metal cam system one turn and its locked but you need to understand these fixtures aren&

;t let me so. Screws, pins other fasterns are accepted was thinking even metal cam system one turn and its locked but you need to understand these fixtures aren& ;t usually used in sheet platic plus you need to make the thickness of the sheet 6-10mm which is ok but thinner the better not too thin but 6mm is about right. We dont mind going up to 10mm but doing so needs to solve the problem in the best way.

;t usually used in sheet platic plus you need to make the thickness of the sheet 6-10mm which is ok but thinner the better not too thin but 6mm is about right. We dont mind going up to 10mm but doing so needs to solve the problem in the best way.

Similar Contests on Cad Crowd

SuperSuv to be hand built for personal use

Off/On Road Super SUV, 3 seater Central driving position like a Mclaren. Rear engined, removable roof which when not in use goes over engine bay. 26 inch rims. Very clean lines. Will use donor lights (pictures included in files). Car must be dramatic with very clean simple lines. Interior must be very simple and clean lines.

I have uploaded many files for inspiration. Countach for rear. Corvette for door treatment. White lotus for air vents. Diablo for roof and body lines.

Bas Relief Panels

Create bas relief panel models to be CNC routed from MDF sheet. I will provide exact panel dimensions, sketches of the design and images to be modeled. Photos of similar examples attached.

create a parametric CAD model

I have a 3d model of an upright that was produced using topology optimisation software. The optimised model provided must be used as a guide to create a parametric CAD model.

The optimised solution will be provided as a solid works file and

I will require the finished CAD model as a SolidWorks file.

I will also provide the original upright design so that you can use it as a reference when creating the new design

I will need the job done by the 15th of october

Engineering design: extending foundation pile support

3 different components need to join together to form 1 piece.

The combined assembly is a clamp on system, that clamps onto 36" diameter pipe, then when hydraulic pistons are activated the arms extend and lock out to approximately 45deg.

I have attached schematics showing in 2d what I am after. Potential for significant future work for winning designer.

Easy Tool Redesign

We are redesigning an existing tool, it is a very simple tool which combines existing parts, Our focus is on portability and a modern sleek design, we require 2d and 3d tech drawings

Payment Pending

Payment Pending

BRAVO