Product design involves developing a new product that is achievable with the appropriate technical expertise, an innovative idea, and effective collaboration skills. This includes the collaboration of expert product designers and mechanical engineers, which Cad Crowd can help you connect you with these professionals, with over 94,000 experts, ready to create your idea into a tangible one. Their collaboration blends functionality with creativity, with the needs of the identification of design aesthetics and the application of engineering principles.

In this article, we’ll look into the details of product design services offered by mechanical engineering companies, including the steps involved, key benefits, and how to identify the right partner for your project.

🚀 Table of contents

The mechanical engineering firms’ role in product design

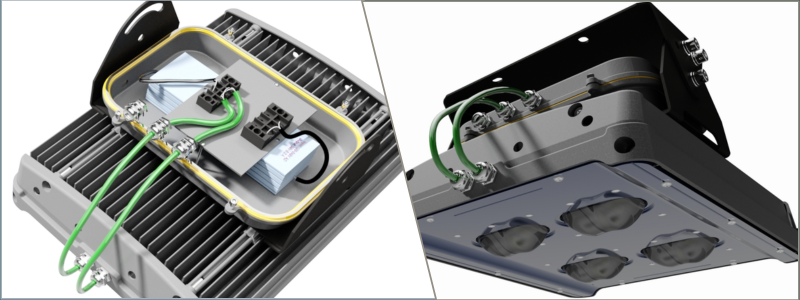

Mechanical engineering companies ensure that the product ideas are turned into reality using end-to-end product design solutions. The solution is used to translate raw ideas into producible, functional, and usable products. Starting from rough concept creation and initial sketching during the initial stages and all the way to precise CAD modeling, prototyping, testing, and being production-ready, mechanical engineering companies are responsible for the entire process.

The greatest argument that can be made on behalf of these companies is that they can equally balance technical innovation and feasibility. The mechanical engineers ensure that not only does the product look innovative, but also aligns with the engineering principles, safety regulations, and the code of manufacture. Their material knowledge expertise, structural integrity, mechanical components, and manufacturability design (DFM) ensure that the product works perfectly under real-world conditions.

Successful product design is an interdisciplinary effort. Mechanical engineering firms will usually use industrial designers to address functionality along with style, and manufacturing firms contribute expertise in cost-effective manufacturing. Cross-functional development, in which style, use, and production considerations align, makes this possible.

By providing end-to-end solutions, mechanical engineering companies allow business organizations to save development time, avoid expensive design flaws, and ultimately benefit from successful products that understand the needs of the market as well as customers.

Product design can be broken down into an incredibly wide variety of stages. Each needs a different set of skills, and mechanical engineering firms are meticulous in completing each one of them with the highest care. The following are the basic steps of the product design process:

RELATED: 10 design principles for product development & industrial design services teams

Conceptualization and ideation

This is where the ideas and brainstorming happen. This is where the engineers and designers will be trying to discover the problem that the product is designed to solve, the market, and the product’s features. A mechanical engineering company will be focusing here on determining the functional specifications, probable materials, and manufacturing procedures.

There is innovation needed here. Companies conduct market research with their fingers crossed to obtain the latest trends, customer needs, and discover other opportunities wherever possible. A product not only must satisfy the need of the customer but also get heard in a competitive space so it survives.

Design development and prototyping

Following the selection of a good idea, the next step is to plan in detail. The technical plans, CAD models, and 3D models will be drawn up by the mechanical engineering experts. These models are the master plan of the structure and product functionality.

Prototyping is the high point now. The engineers will create a prototype to witness the design in action. Prototypes enable the team to ascertain how the product’s performance, ergonomics, and solidity are and where issues can arise in making it. It’s all done iteratively before actually arriving at the end product.

Engineering analysis and testing

A product should be tested before they are made. Mechanical engineering businesses typically carry out a set of analyses in their effort to determine that the design is up to standard. In such instances, analysis can mean stress analysis, thermal analysis, vibration analysis, among others, to mention but a few.

In this case, engineers apply software such as Finite Element Analysis (FEA) to model the product’s behavior in various circumstances. They attempt to locate defects in design and correct them before they make the product in volume.

Final design and manufacturing preparation

Once the design has been finished and verified through analysis and testing, the product will be ready to manufacture. Including enough specifications, choice of material, and identifying the most appropriate way of manufacture will be involved. The manufacturing design service will be aided by the mechanical engineering company in the economical, efficient, and highest quality manufacture of the product.

Mechanical engineering companies play a vital role in ensuring the procurement of mechanical tools required and production ramp-up whenever needed. Mechanical engineering firms make assembly lines easy and prepare the tools ready for production at full capacity, since it needs to be accomplished without affecting production quality.

Advantages of hiring the services of mechanical engineering firms

Collaboration with mechanical engineering companies in product design has a host of benefits. The companies are highly skilled and experienced in their line of work, and they bring a lot of quality into the final product. Some of the best benefits of collaborating with mechanical engineering companies in product designing are:

Technical competence

Technical ability in mechanical engineering allows them to design a product not only good-looking but also economical and easy to produce. From what they learn in strength of materials, thermodynamics, and material science, they can make the final product safe and efficient.

Cost effectiveness

With the assistance of experienced mechanical engineers, businesses can prevent expensive design and manufacturing flaws. The engineers can be instructed on how to engineer so that they can minimize the wastage of the material and the additional expenditure. The engineers can establish how they can make the manufacturing process streamlined so that it leads to enormous amounts of money saved through consumer product design services.

Savings of time

On-time timing is of most importance in product design. Mechanical engineering firms are able to accelerate the design cycle by utilizing their talent and expertise. From quicker-than-a-before-published-version-of-design to accomplishing revisions within a half-year required timeframe, firms bring them to the marketplace doorstep earlier.

Reduction of risks

Product design itself poses risk if it involves new materials or the use of technology. They are sorted out by mechanical engineering firms through thorough testing and inspection. Given a chance to locate mistakes beforehand, they sort out money-redesigns or safety concerns at mid-product development stages.

Collaborative innovation

The mechanical engineering firms would be moving in the direction of product design according to a multidisciplinary approach. Through a multidisciplinary interaction between software experts, manufacturing specialists, and industrial designers, they can form revolutionary products. Multidisciplinary design does have a scope to bring forth design innovation, increased functionality, and better usability.

RELATED: How to improve product development for your company with engineering firms & design consultants

How to choose the perfect mechanical engineering partner

Selecting the most appropriate mechanical engineering firm to design your product is a make-or-break choice that will kill or give life to your project. The most important factors to observe while selecting the right engineering partner are as follows:

Familiarity in your industry

While the majority of mechanical engineering companies provide various services, a company that previously worked in your business should be sought after. Whether it’s designing consumer products, medical equipment, or manufacturing machinery, working with a firm that knows about the regulations and complexities in your business is the key to success.

Established track record

Seek out a mechanical engineering company with a past record of timely, within-budget project completion. Check their list of comparable projects they have previously completed and inquire of past customers for references or case studies to determine whether or not they are able to complete it on time, on budget, and to spec.

Communication and cooperation

Product design is highly team-oriented, and communication is excellent. Select a mechanical engineering company that loves to communicate and will bring your ideas to life. A company that loves being part of a team will be more enthusiastic about your success and best suited to assist you in creating better designs and solving problems.

Innovation and creativity

Product design needs technical expertise and forward-looking minds. Choose a mechanical engineering firm that is evolving new developments and is willing to challenge standard principles and procedures. Good companies are innovators who will challenge what can be accomplished and bring in new thinking to their product. Though it’s worth noting that some companies specifically offer open innovation services for clients needing a little bit of professional insight.

Dedication to quality

Quality must be of the highest concern in every step of the product design process. Make sure the company you select adheres to some extent to industrial standards and regulations and prioritizes quality in creating long-term products as a first priority. Quality control processes must be followed at every step, from conceptualization to production.

Scalability

If your product is successful, you’ll need to scale production quickly. Choose a mechanical engineering company that has the resources and capabilities to support increased production volumes. They should be able to work with manufacturers to ensure smooth scaling and that quality is maintained as production ramps up.

RELATED: Proven tips to build a strong engineering team for your firm with freelance services

Conclusion

Product design is a lengthy and complex process that requires collaboration by several experts, the most notable of whom are mechanical engineers. With the collaboration of the right mechanical engineering firm, companies can design products that not only save them money and last long, but also use less energy. Conceptualization of the product is derived from the interaction between product engineers and designers, such that the product has a good quality in each and every aspect, starting from design to production.

Cad Crowd to the rescue

When selecting a prospective business partner in product development, inquire about the qualifications, experience, and compatibility as a team. You will be developing a winning product that is customer-focused, a market trendsetter, and has a fantastic foundation. The best news is that Cad Crowd can lead you to suitable mechanical engineering companies today. Call us now and get a free quote.