If you are new to CAD software, the array of features stuffed into many high-end programs can be dizzying. Truly learning all of the features in a CAD program is time-consuming and may not be part of the training in a typical office. Some companies providing CAD drafting and design services deliberately choose very simple CAD software because it’s easy to learn, but that’s not necessarily the best solution.

The trade-off of using easy-to-learn software is that it’s usually simple to learn because it’s almost featureless. By narrowing a program down to just a few popular features, you cut the many hours it takes to learn the product and make navigation simpler. Yet, you also reduce the number of things you can do with a product.

Rather than choosing design software that is simple but limited, there are a lot of great reasons why you should choose a more robust software that gives you the freedom of choice.

Here are a few reasons why you should choose a robust CAD design software over a simpler product.

6 Reasons to Use Robust CAD Design Software

1. Robust Software Offers Parametric Modeling

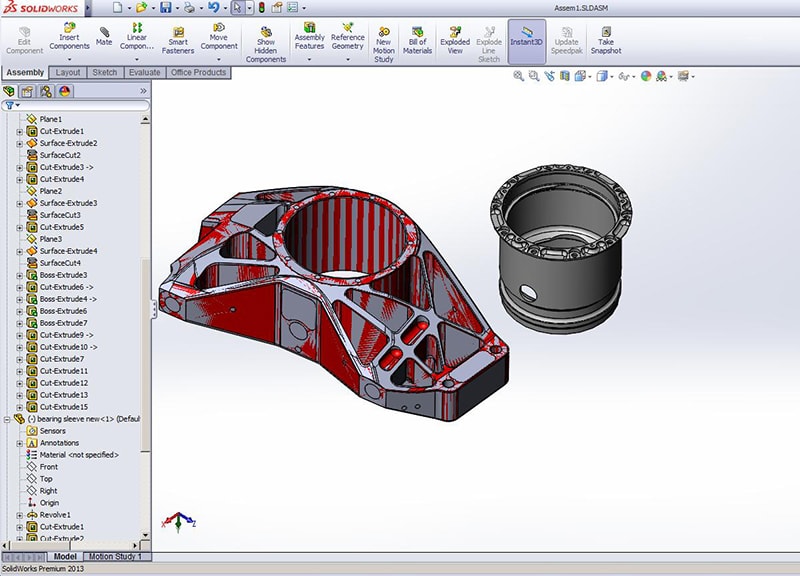

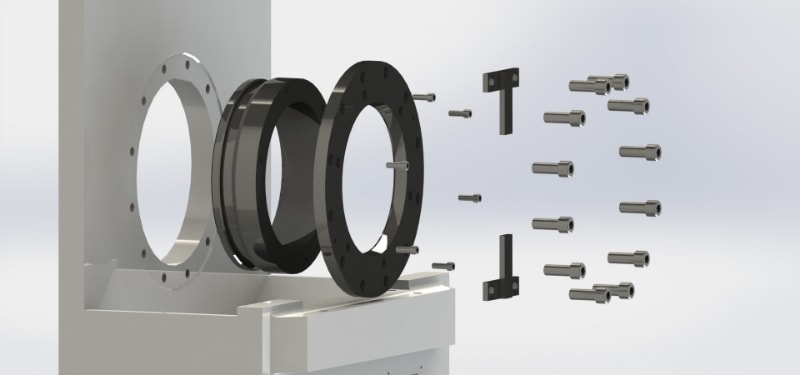

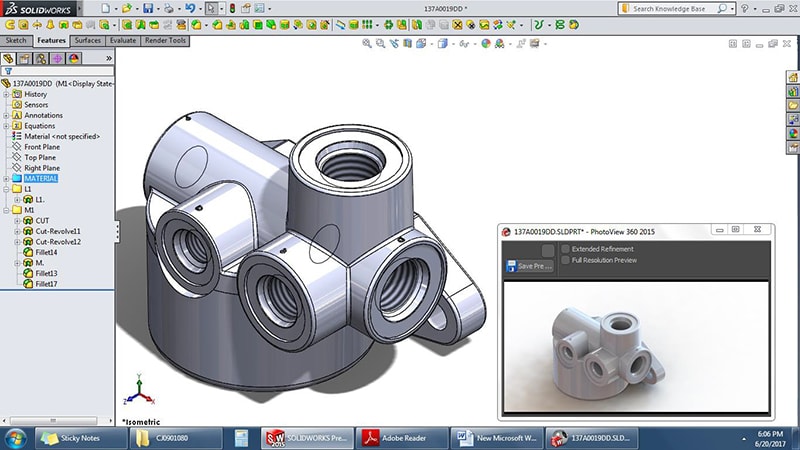

There are two basic forms of 3D modeling design services. Direct modeling, which allows you to work directly on the 3D image, and parametric modeling, which works on the model piece by piece. Direct modeling tends to be faster and is more popular, but parametric modeling has a full range of uses that are not to be ignored.

Parametric modeling has several advantages. If you work on products where a certain part is used frequently, you can save the individual piece of that model for later, saving time by not having to individually model that piece over and over again. These models can also be passed on to other CAD designers.

Long-term convenience isn’t the only reason parametric modeling has been the gold standard in 3D modeling since its inception in the 80s. It’s also a favorite because you can use it to analyze the strength of the materials you are using, and figure out how strong a product will be before you even create it.

This might not seem important, but if you’re working in architecture and are planning a building, knowing the strength of your materials is extremely valuable information.

Of course, parametric modeling has its downsides. Its very nature makes it fairly inflexible, something direct modeling excels at. It also takes longer since the product must be made piece by piece rather than all at once. Still, having all the options is important if you want to be one of the best in your field.

2. Freestyle Modeling

Another style of modeling involves building a 3D model using methods similar to that of working with clay. Freestyle modeling is ideal for organic shapes, which for a long time have been difficult to create in CAD.

That’s because while CAD, with its mathematically based design, excels at creating pre-defined shapes, in a freeform world where you might be designing an ornate chandelier, what might seem like a simple piece is in fact very complex.

Freestyle modeling makes designing free form shapes easier and gives you yet another tool in your arsenal to be more creative.

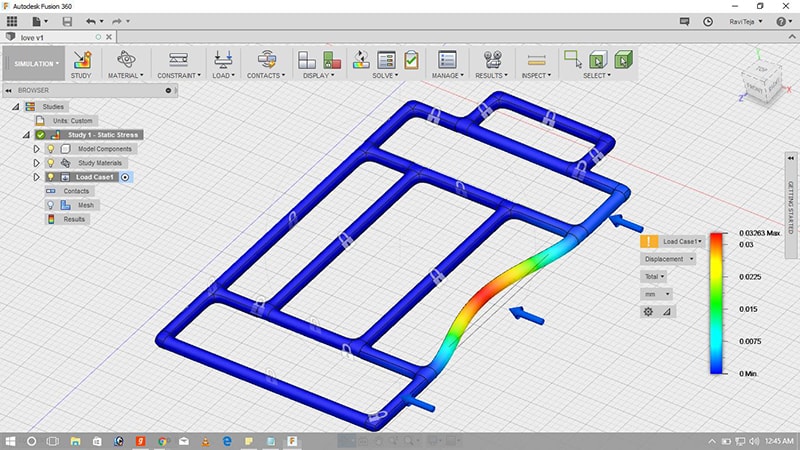

3. Simulations

Making a 3D design of a product isn’t just about product visualization. 3D models provide critical data before testing of a physical product, to cut down on the need for multiple testing phases, and increase the safety of the devices being used.

In the case of architecture, you don’t want to find out after a building is finished that the frame was too weak, so testing it without physically creating the building is a must.

Simulation modeling is a safe, cost-effective, and valuable solution for collecting this data. By modeling the product or building in the CAD software, you can test various junctions and materials to see whether an arm or joint will give way, and if so, in what situations.

The applications on this are universal and can save lives. Checking the safety of a doll with moving parts is sensible before giving it to a child. Testing parts on a car before creating multiple test vehicles both increases safety and reduces the number of cars needed for testing.

Every year, dozens of products make the news for spectacular fails, some of which resulted in the death or injury of the customer. Testing the product via CAD software can help make sure that your company isn’t the one making the news.

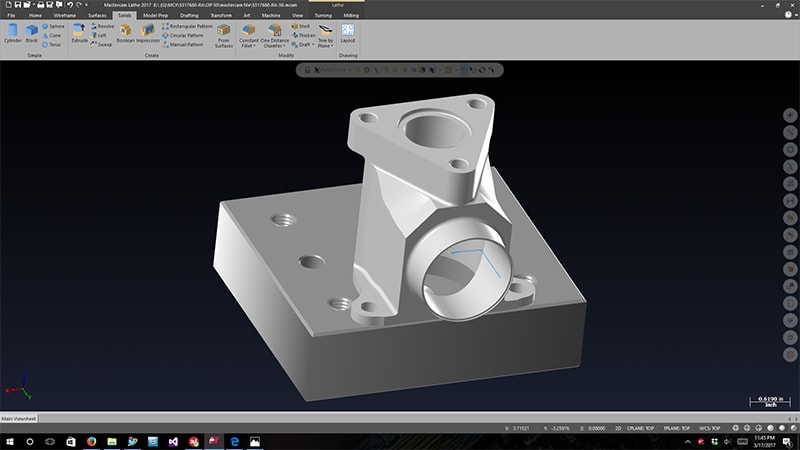

4. Skeletons/Top-Down Modeling

In many situations, you are not the only designer working on a product. You may be asked to work with a team of other CAD services, or you may be working on the upgraded version of a previous product.

In the case of an upgrade, it makes little sense to start from scratch and build the whole thing from the very beginning or to create the parts made by other designers yourself.

Top-down modeling works by giving you a core set of files to base your work off of. Instead of working independently and doing everything from scratch, you work within the parameters already put in place.

In some cases, the skeleton of the model is already in place, or there may simply be an assembly file or parts file available for reference. In either case, this method of modeling is a lot faster than developing the same file from scratch and can help create products that are cost-effective and obviously from the same line.

5. Design for Downstream

Looking ahead to who will be handling the product at every stage of development is also an important factor in business. If the product involves hazardous material, thinking about the employees who will be handling the material on a daily basis is an important safety step.

Today’s consumers are conscious of the safety of employees, as evidenced by their demand for fair trade products, and the popularity of various logos that look after the safety of employees, such as the fair trade logo and the B corps logo.

Employees aside, if the product contains hazardous material (such as the lithium in certain reusable batteries), it’s necessary to make sure that it is as safe as possible for the end-user.

Thinking about things such as occupational exposure and user safety are both clear examples of downstream modeling, but they’re not the only important aspects of this type of modeling.

Other downstream people to take into consideration include the advertising department and other team members who are not part of the design process. All of these people may need to handle the product or the 3D model, but may not necessarily have the understanding of how to operate CAD.

Robust CAD software has several downstream applications that can make your product safer or more efficient. This includes things like being able to share the model in easy-to-use readers so that other members of the team can stay updated in the process.

Some software also has tools that allow you to easily email it. So, the model can be used by others for advertising purposes, or by team members reviewing it for safety.

The flexibility of the model is important to ensure the whole process of turning it into a real product or building is very important, and having the option to email it or view it in a reader is one more valuable tool robust software has that simpler program might not.

6. Multi-CAD Capability

It takes a long time to fully learn a complex piece of robust CAD software. There can be hundreds of different tools in a program, and learning how to use them all proficiently takes more than just the few weeks of training CAD designers often receive.

The solution is usually to have designers use one or two fairly simple programs with fewer tools, and switch between them when new tools are needed. While this may be less confusing, the results can be a mix of different CAD software—an average of 2.6 per office worldwide.

A robust program not only limits the number of CAD programs needed; some of them have a multi-CAD capability, allowing you to use different CAD programs all rolled into one.

Don’t Let the Price Deter You

If using a program with a whole lot of features (and yes, usually a larger price tag) scares you, face your fears and try out the more robust software anyway. Despite the longer learning curve, you’ll have more tools at your disposal, allowing you to be more creative, get more done, and helping you to resolve more of today’s problems.

Robust software is packed with tools because all of them are useful, and all of them are necessary to be well-rounded in CAD. Give a robust program a try, and see how exploring new tools can help you be more efficient, design safer products, and reduce the need for dozens of testing stages. There are plenty of CAD programs available with great tools; all you need to do is explore them.

Cad Crowd Has Freelance CAD Designers

If robust CAD software isn’t an option for you at the moment, you can always rely on the services of freelance CAD designers. Cad Crowd has a database freelance CAD design professionals from all corners of the globe. They are skilled, experienced, pre-vetted, and confidential.

Find out how it works and start enhancing your CAD projects today.