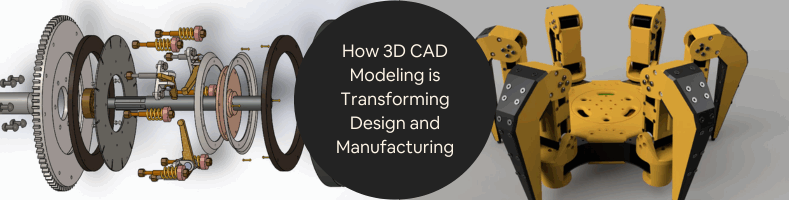

Think of the most recent time you were impressed by a great product—be it a new sleek phone, a futuristic car, or a beautifully crafted piece of furniture. Behind the product is a powerful and sophisticated tool that helps in converting abstract ideas into tangible products: 3D CAD modeling design services.

Cad Crowd is a leading agency that can help you connect with over 94,000 experts and professionals who use 3D CAD Modeling as a game-changer in every design. Sector by sector, 3D CAD modeling has changed the way products get designed, tested, and manufactured, rendering it the building block of innovation for design firms globally.

At the end of this article, you’ll be able to understand the potential and advantages of using 3D CAD Modelling in leveling up your design, whether you’re a small company or a well-known company.

🚀 Table of contents

- The magic behind 3D CAD modeling

- From concept to creation: A new era for product design

- Testing without limits: Simulations in the virtual world

- Cutting costs and cutting timeframes

- Collaborative design and communication: A solution in one

- Revolutionizing manufacturing processes

- A sustainable future: Reducing waste and increasing efficiency

- The road ahead: The future of 3D CAD modeling

- Conclusion

- How Cad Crowd can help?

The magic behind 3D CAD modeling

Essentially, 3D CAD modeling involves the computer-produced replica of three-dimensional representations of objects in real life. Through the use of specialized software, designers and engineers create accurate virtual models that have every nuance of the final product. In contrast to traditional 2D drawings, 3D models give product design companies a fuller and more accurate idea of how a product will function and look through simulations.

But what’s so potent about 3D CAD modeling, anyway? The answer lies in its versatility, productivity, and the staggering advantages it brings to every stage of the product lifecycle.

From concept to creation: A new era for product design

Imagine you’re working on a cutting-edge electric car prototype. Previously, developing a vision like this involved creating physical models, testing them, and repeatedly refining them, which cost both time and money. With 3D CAD modeling, however, all of that is done within the virtual space before a single part is manufactured. The design team can design and visualize every part of the car’s system in half the time it would take to construct and test real-life models.

The “magic” in this case is the precision of 3D CAD modeling. When designers can see how parts go together in a virtual environment, they can spot issues early on—issues that might only be found after a few rounds of physical prototypes. This reduction of errors in the initial design phase alone translates into massive cost savings, less downtime, and faster time-to-market for new products.

Second, this software isn’t for freelance CAD designers alone. Cloud-based systems bring everyone involved in the project—whoever they may be—into the picture, from engineers and producers to customers and stakeholders, to see the same model at the same time, allowing them to offer immediate feedback and collaboration. The days when design teams used to work in isolation are over. Now, everything fits into one virtual arena.

RELATED: 10 design principles for product development & industrial design services teams

Testing without limits: Simulations in the virtual world

One of the greatest benefits of 3D CAD modeling is that the design can be tested in a virtual space prior to creating something physical. That is where simulation technology takes place. With virtual prototypes created, design teams can have the performance analyzed, stress tested, and mimicked in real-life scenarios. Whether it’s testing how a new machine will handle hot temperatures or how a new smartphone design will handle drop testing, these simulations provide key information to finalize the product.

CAD software allows us to perform simulations that would be too time-consuming, too costly, or even impossible to perform using physical prototypes. For instance, imagine testing a highly intricate mechanical part that needs to endure significant wear and tear. With traditional methods, you’d have to create multiple iterations of the part and test each one—an expensive and resource-draining process. However, with 3D CAD models, this can all be done in a matter of hours or days, cutting down on costs and boosting efficiency.

This also opens up avenues for design experimentation. Engineers have the freedom to innovate and experiment with new shapes, geometries, and structures in their models without worrying about the physical expenses of prototype design engineering services. It is this liberty that has given birth to innovations ranging from automobiles to consumer electronics.

Cutting costs and cutting timeframes

In short, 3D CAD modeling lowers the cost of product development considerably. Previously, manufacturers used to spend money on multiple prototypes, testing stages, and changes—all of which consumed a lot of time, effort, and resources. With 3D CAD models, companies can easily identify defects, enhance designs, and make changes without the need to produce physical prototypes.

For example, in industries like aerospace and automotive manufacturing, parts can be simulated, tested, and refined in the virtual world before they’re even built. This reduces waste generated during the prototype stage and accelerates the entire time horizon for getting a product to market. With smaller development cycles, companies are able to stay competitive and react more quickly to shifting marketplace demands or new technological advancements.

Collaborative design and communication: A solution in one

Given that teams tend to be dispersed geographically, collaboration is sometimes akin to an administrative headache. 3D CAD modeling relieves this pain by allowing design teams to collaborate on the project in real-time, regardless of their location. Cloud-based platforms ensure that any changes one designer makes can be seen instantly by everyone, generating a flow of ongoing communication and feedback.

This also has strong implications for client communication. Instead of sending clients flat outlines or 2D blueprints, designers can now send them fully interactive 3D models through 3D rendering services that provide a better sense of understanding of the product. Clients can view designs from any perspective, zoom in on specific areas, and even request changes on the fly. This degree of interactivity fosters a more interactive and open client experience that ultimately leads to higher satisfaction.

RELATED: Why architects outsource 3D modeling services and the benefits for your design company

Revolutionizing manufacturing processes

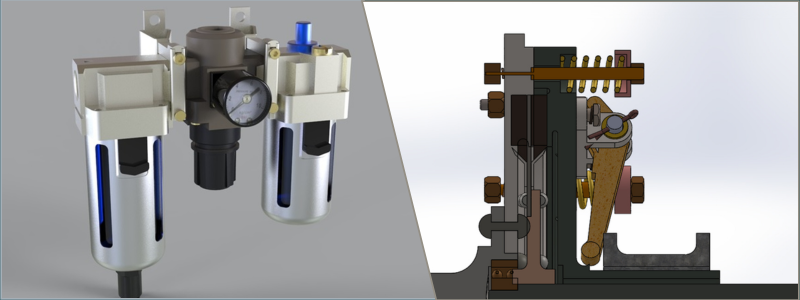

The effect of 3D CAD modeling extends far beyond the design stage—it’s transforming the very manufacture of products. When a 3D model is complete and ready to be translated into a physical product, the information contained within it can be transferred easily to machines. In advanced manufacturing environments, such as 3D printing or CNC machining, CAD files are linked directly to automated manufacturing systems, giving a smooth and streamlined process from design to production.

In fact, 3D printing has become a significant partner to CAD modeling. With the ability to transform a digital model into a physical object, typically within a matter of hours, there are newly available options for rapid prototyping and low-volume manufacturing. Design companies can quickly print out prototypes and test them in the real world virtually instantaneously, leading to faster feedback loops and improved products.

This is especially worth it in those industries that have custom or highly specialized products. From medical implants tailored to an individual patient to high-performance components for racing cars, 3D CAD modeling and 3D printing design services allow manufacturers to produce complex geometries with extremely high accuracy at a fraction of the cost.

A sustainable future: Reducing waste and increasing efficiency

Sustainability is now a foremost concern for companies in all fields, and 3D CAD modeling is assisting manufacturers in reducing their carbon footprint. With the use of simulations and optimizations, designs are more resource-friendly and still an efficient product. With precise 3D modeling, less material is wasted in manufacturing, and with the optimization of the entire product design, companies can create longer-lasting products that avoid replacements.

Also, the potential to create virtual prototypes means fewer prototypes and less material is consumed. This is particularly pertinent in those sectors whose production involves significant material or energy-consuming manufacturing, e.g., aerospace engineering services or automotive manufacturing.

The road ahead: The future of 3D CAD modeling

As technology continues to evolve, the application of 3D CAD modeling will continue to increase. Breakthroughs in artificial intelligence, machine learning, and automation will only continue to streamline manufacturing and design. In an AI-powered design software, designers are able to have an assistant in developing solutions for optimizing functions in the design, including strength, weight, and material choice.

Virtual and augmented reality are beginning to make appearances in the 3D CAD world as well. With VR, customers and designers can walk inside their 3D designs and see and feel as though they’re handling the product in real life. AR would provide real-time co-design between manufacturers and designers so that a designer could overlay a virtual model over a real environment to ensure a perfect fit.

The collaboration can potentially make 3D CAD modeling even more powerful, productive, and design-focused. What was once an indulgence reserved for large companies with fat coffers is now accessible to small start-ups and solo freelancers, leveling the playing field open for innovation.

RELATED: Concept to reality: How product rendering services transforms companies products & marketing

Conclusion

3D CAD modeling is no longer a tool; it’s the basis of modern design and manufacturing design services. From enabling rapid prototyping to improving collaboration and saving costs, it’s revolutionizing the way products are conceived, designed, and brought into being.

The ability to test, iterate, and visualize in a virtual world is simpler than ever before, producing innovative, both useful and aesthetically pleasing products. As time goes on and the pace of technology increases, there will be more advancements in 3D CAD modeling with more opportunities, paving the way to future design and manufacturing innovation.

How Cad Crowd can help?

Whether you’re an established company or a small design firm, embracing 3D CAD modeling from the experts. Here at Cad Crowd, you can ensure that every expert’s mindset is to stay ahead in an increasingly competitive market using advanced technologies and skills. Call us today for your free quote!