In the world of design and construction, accuracy is an important quality. Technical drawings are what architects, engineers, component fabricators, and builders rely on to ensure accuracy and precision throughout any project. It also serves as a tool to help architects, engineers,and other professionals in the design and construction to help them visualize design concepts and communicate,and reconstruct design ideas efficiently. One of many construction documents required and produced in an architectural project are shop drawings and as-built drawings. These drawings play a big role in the component fabrication process and for project review purposes.

Cad Crowd is a leading platform providing the best architectural design companies with vetted and highly experienced shop and as-built drawing services. Let’s take a look at their differences.

🚀 Table of contents

Shop drawings

Shop drawings are technical documents that describe and define the design of pre-fabricated components in a project, such as buildings. It is usually encountered in architectural projects that are dedicated to the construction and installation of MEP (mechanical, electrical, and plumbing) systems. The key term “prefabricated” indicates that the components to be used are of a mass-produced kind, such as piping, precast concrete, trusses, fire protection, metal ductwork, appliances, and so forth.

MEP components need shop drawings, but you might encounter similar documents referring to some furniture products. This is true, but only if the clients want their furniture pieces constructed from prefabricated parts. In case they specifically ask for custom furniture built from milled components, what you need is a millwork drawing instead. Shop drawings are among the “must-haves” in most architectural projects, both residential and commercial, and now with the rise of prefab and modular construction technology, chances are you’ll see quite an increase in the shop drawing services sector, too.

One of the main points of shop drawings is to provide specifications and detailed illustrations of how the prefabricated components should be procured and assembled to build a specific component. Architects, designers, and engineers provide the design intent as a general visualization of the final product, but the actual shop drawings must be produced by the person in charge of sourcing and assembly. In a typical architectural design firm, this person could be the general contractor, subcontractor, or supplier. Shop drawings are not general blueprints; they’re tailored to highly specific systems, designs, or structures in a project. You’d have a better guarantee of accuracy when the drawings are produced by someone who actually understands the ins and outs of the components.

RELATED: BIM vs. CAD: Which is better for modern architectural design services companies

What to watch out for in a shop drawing

Shop drawing isn’t an artistic drawing; it is a visual representation of a construction plan proposed by either an architect or a designer. It’s pretty technical, filled with information on materials, dimensions, assembly instructions, etc. A shop drawing is practically a communication tool to bridge the gap between the design plan and the actual build. To minimize the possibility of miscommunication, a shop drawing needs to include important points as follows.

| Points | Purposes |

| Sections and elevations | Every single component must be attached with dimension information, including height, length, width, diameter, and all other relevant measurements. It goes without saying that all the prefab components must fit precisely within the structure. A shop drawing also has to provide a view of the final product with the correct dimensions. |

| Dimensions | A shop drawing service must specify the materials used for the prefabricated components. Additional details may include material grade, finish, type, and characteristics if needed. |

| Materials | Certain prefabricated components may require further processing, such as cutting and shaping to match the defined design specifications, so you should be able to find the instructions in the shop drawings as well. In case the design uses a lot of raw materials that need some more elaborate treatments, you can use another document (fabrication drawing) to provide the instructions. |

| Detailed views | When the design is complex enough that it requires small mechanisms or intricate details, the shop drawing provides enlarged views of those specific parts for clarity. Fabricators and installers refer to these “detailed views” to understand how the parts must be assembled. |

| Shaping | Certain prefabricated components may require further processing, such as cutting and shaping to match the defined design specifications, so you should be able to find the instructions in the shop drawings as well. In case the design uses a lot of raw materials that need some more elaborate treatments, you can use another document (fabrication drawing) to provide the instruction. |

| Bill of materials (BOM) | `Every single part and component you need for the design is listed in the BOM. Details include quantities, part numbers, specifications, and descriptions, and are essential for architectural planning and design companies. |

| Symbols | Symbols are used to indicate welding locations, sizes, and types. In many cases, you can omit these symbols entirely if you have a separate fabrication drawing. Usually, this is used in a design where metal components need welding. |

| Assembly information | An illustration of how the various components are assembled together. Some assemblies require different fasteners and connections, so you should make sure that all those details are clearly specified. |

| Finishing | An instruction on how to apply the specific types of coating, textures, or colors. |

As mentioned earlier, shop drawings are custom blueprints for specific designs. They’re quite elaborate, for they must convey all the information you need to fabricate components and build the assembly correctly.

Note about metal components: depending on the design, some metal components must be welded together or fabricated in a particular fashion before you can assemble them with all the other parts, for example, in piping or plumbing installation.

Some welding jobs are simple enough that you can actually include the instructions for them in the shop drawing. For anything more complex than the simplest kind of MIG welding, you’ll need to provide instructions in a separate technical document known as a fabrication drawing through metal design and fabrication services. The design drawing, especially between the shop drawing and fabrication drawing, can be different depending on the level of detail pertaining to the fabrication technique. Fabrication drawing provides details even up to the smallest information, welding tasks, and provides symbols and measurements for every section.

RELATED: 3D apartment rendering and how revolutionized real estate with 3D visualization firms

Why is shop drawing important

Not every construction project needs shop drawings, but it doesn’t change the fact that they’re important to ensure design accuracy and speed up project completion. Here are some key aspects in an architectural project where you might find shop drawings invaluable:

- Coordination: Shop drawings are technical construction documents. As such, they function as a means of communication between all parties involved in the project, including but not limited to the architect, engineers, designers, contractors, subcontractors, fabricators, builders, and clients. Shop drawings are the points of reference when you’re coordinating the construction, keeping everyone on the same page.

- Design visualization: architects, engineers, or designers produce the design intent – sketches that represent the basic geometry and dimensions of a design. Contractors or suppliers interpret those sketches and transform them into a much more detailed visualization, albeit a two-dimensional one.

- Shop drawings provide a more detailed view that consists of specific dimensions, construction methods, materials, etc, compared to sketches. After finalizing shop drawings, the architectural design expert reviews for approval and checks if the interpretation is exactly as needed. In case there are inconsistencies between the drawings and the original plan, it must be revised. From there, it can only proceed to the construction/fabrication when all details are correct.

- Guidance: If an architectural project involves a lot of designs, objects, or products constructed from prefab components, shop drawings must be treated as the only fabrication guidance. So long as the drawings have been approved by the architect or engineers in charge of the project, there’s almost no need to look for any other references.

There’s also quality control. Because shop drawings provide detailed fabrication guidance, you should be able to identify any mistakes in the finished work by cross-referencing it with the drawings, too. Assuming the project is large enough that the construction requires permits, shop drawings are also part of the documents to ensure compliance with local building codes; as in, you can’t acquire the permit or even apply for it without having shop drawings.

As-built drawings

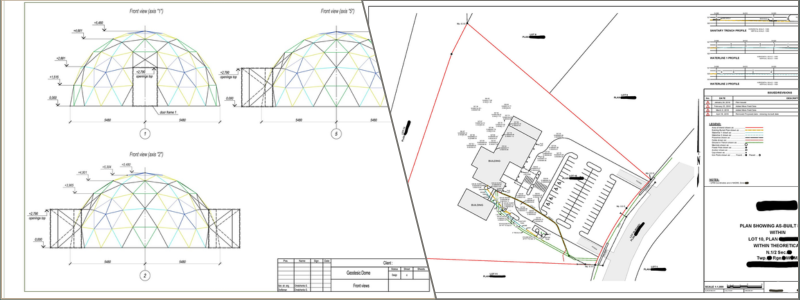

A construction “as-built” drawing (also known as red-line drawing or record drawing) is the technical document that offers an overview of the final design. It might be used as a comparison tool to verify whether the end product comes out exactly as planned. Think of it as a blueprint compiled after the project concludes. Of course, the point is to showcase, in detail, how the project is actually built.

In an ideal world, every architectural project goes exactly as planned. But this is rarely, if ever, the case at all. An as-built drawing is submitted upon the completion of a project to reflect all the changes made during the construction process.

Such changes might include alterations in specifications, design geometry, locations of components, and basically all other works completed over the duration of the project and under the contract. Even the changes in shop drawings, for example, when prefab components need further treatments to fit the desired specifications, are also included in the as-built documents. Keep in mind that none of those modifications are made without approval from the architectural design and drafting firm and the clients.

But just because the drawings are submitted upon completion, it doesn’t necessarily mean they’re created as soon as the project ends. If you can allocate the time and budget, it’s best to schedule as-built surveys throughout the duration of the project. The surveys track how the construction progresses over time and create “partial” as-built drawings as they go. As long as there are no further modifications to the already “surveyed” sections of the project, you can simply compile the partial maps into one single drawing in the end. This makes the process much easier and quicker than having to retrace everything all over again.

RELATED: 6 types of residential design & CAD services for companies

What to include in an as-built drawing?

To make an as-built drawing as clear as possible, so that it may serve its purpose well as a review tool, you must include quite a lot of documents containing a lot of details. At the very least, these are the things you should see:

- Record of changes in scale, but ideally, this should not be a problem as long as you use the same scale as the original blueprint.

- Clear labels to identify changes, instead of vague phrases like similar to, equal to, taller, bigger, or any potentially ambiguous terms, without mentioning additional details.

- All records of changes in sizing, dimensions, locations, fabrications, installations, assemblies, materials, textures, and so on.

- Specific dates when every single one of those changes occurs.

- Notes on unexpected challenges encountered during the project, and the solutions implemented to solve them.

- Notes about changes proposed during the final inspection.

- Shop drawings, original blueprints, and appendices.

As-built drawings are usually signed by the architect associated with the original blueprint, and shop drawings are created by contractors and suppliers during their contract with the project. In case you hire your own architect, their role is to record all the changes made to the design, as they are the most qualified to do the task because of their familiarity with the intended design.

If you’re running a small architectural firm without in-house drafters, you can always outsource the task to third-party CAD service providers or freelancers. However, since the architects have the final say to approve the design, it doesn’t really matter who actually produces it. In case there are mistakes in the drawings, you’re allowed to ask for revisions, too. The same thing applies to shop drawings.

Why should contractors care about as-built drawings?

Although submitting as-built drawings is not always mandatory in every project, the documents serve as important components of any finished project. They’re the most accurate representation of what was actually built in the first place, and will be indispensable references when you need to modify, expand, renovate, and build on top of the old work.

If you’re a general contractor, you might be wondering why you should prioritize producing and submitting an as-built at the end of a project. As a matter of fact, you shouldn’t be focusing on creating an as-built throughout the project at all; instead, you should strive to maintain or improve your work and quality to be reflected in the as-built.

The truth of the matter is that as-built drawings can’t really affect the construction at all. But it can do wonders for your reputation as a company and bring more businesses in the future. As for subcontractors, as-built drawings are especially important if you’re hired to do a renovation and a maintenance project. Once again, the as-built will be your most dependable document of reference to improve your chances of completing the job with great success.

Finally, as-built drawings are proof that the architects, contractors, engineering design firms, designers, subcontractors, and fabricators have moved on from the project. They’ve done what they’re hired to do, and you can always take a closer look at what they made from the submitted and approved as-built drawings.

RELATED: How design drawings help avoid interior design mistakes for 3D design companies

How Cad Crowd can help

Whether you need a shop drawing for specific building components, an as-built drawing after the completion of a big project, or as-built surveys to help you compile the final document, Cad Crowd has just the right professionals to get the job done. We are home to some of the most experienced drafters in the country, offering services to companies and individual clients alike at affordable rates. Contact Cad Crowd now to get your free quote.