As a CAD service company, you must be flexible and adaptable. CAD technology is evolving continually; to that end, your business must also change. You must be able to provide a varied and robust service to your end customers. Diversity is key, as is the ability to meet the requirements of a range of customers in different industries.

This is why using a robust and high-quality CAD software suite is important. In the following article, we look at the reasons why a robust software package is important. Moreover, we consider the ramifications of choosing the wrong CAD software.

Why Choosing the Right CAD Software Is Important

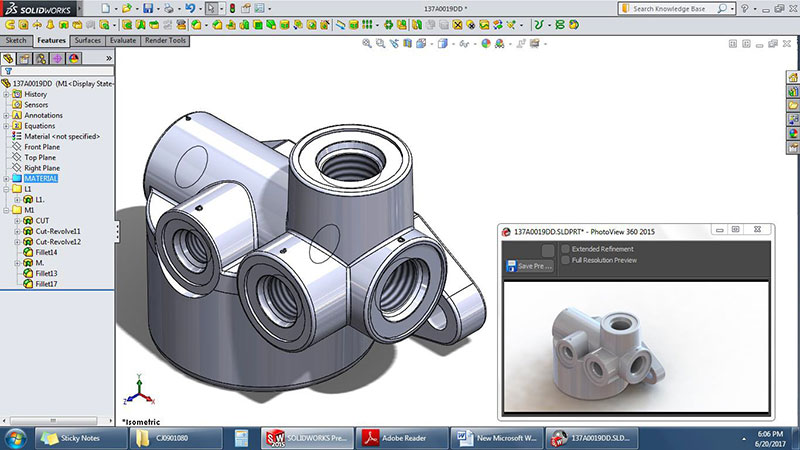

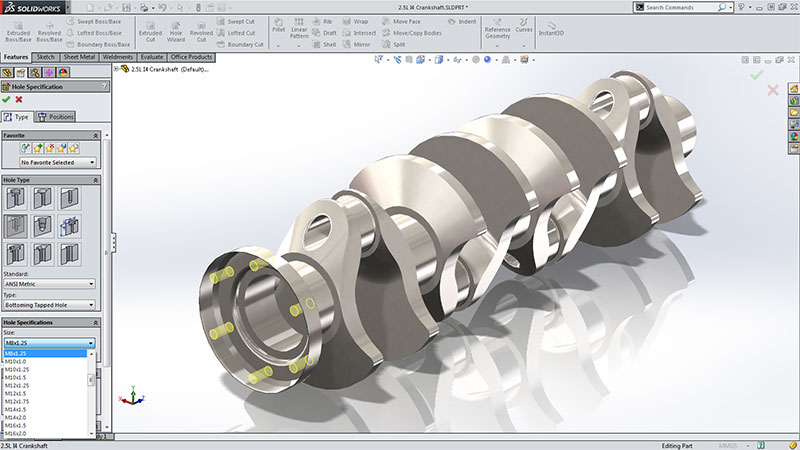

The software market is flooded with different CAD programs. We have popular titles such as AutoCAD, SolidWorks, CATIA, FreeCAD, and Fusion360. These are just some of the well-known products – there are hundreds more available. If you choose the wrong program, you could encounter the following issues:

- Insufficient tools to create design specifications for customers

- Poor workflow management resulting in a slow process

- Ineffective costing for the design process

- Inability to react to customer demands

- Lost time rectifying errors

As you can see, the issues are various and can be severe. Your CAD service business revolves around the usage of CAD software. Obviously, choosing the wrong program can, therefore, affect your whole operation.

Some businesses may opt for a cheap CAD suite. This may seem like a fantastic solution – the software cost is negligible – fantastic! But what costs will you incur and what business will you lose when you find that the cheap CAD software is inadequate for your requirements?

Low cost is not always beneficial. Indeed, in the CAD industry, this can be a hindrance. As you will see below, a robust CAD design program (that may be more expensive) will pay for itself in numerous ways. The investment is almost always justified in the long term.

Reasons Why Robust Design Software Is Essential for CAD Service Companies

We have discussed the implications of choosing the wrong software. Now we can look at how choosing the right CAD software is actually beneficial. We have listed seven main reasons why robust design software is imperative for this type of business:

Greater Design Control Using Freestyle Modeling

Control and flexibility is an important part of CAD design. You must have 100% control over the design process. Without this, you may not be able to meet your customers’ demands. For example, let’s say your customer wanted a specific design element with extremely tight tolerance. What would you do if the CAD software you were using couldn’t achieve this? You could potentially lose the job and have to turn away revenue.

CAD software with freestyle modeling can help give fantastic control and design freedom. Freestyle modeling allows you to design a myriad of free-form surfaces and concept designs without constraints. This all still works within the basis and discipline of parametric. However, you get the best of both worlds. Freestyle modeling is not freely available in every CAD program. Generally, only robust software programs will offer this design feature.

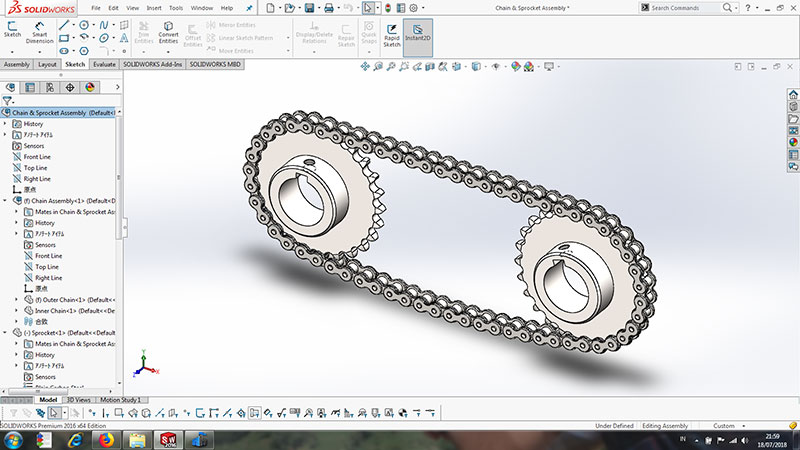

Improved Time-Saving Due to Parametric Modeling

Within the CAD industry, time is important. If you can create a design two days quicker than your competitors, you have an edge. This is why any time-saving measures you can use should be jumped upon immediately. Parametric modeling is one such way that you can save time (and subsequently costs).

When creating CAD designs and 3D models, parametric modeling is a huge time saver. In traditional modeling, if you edit one element of the design, you would then have to edit the whole design too. For example, you have designed a new machine. The customer has requested changes to a specific part of the machine’s mechanism. Without parametric modeling, you would have to change the parts, and then change the whole design – this would be a lengthy process.

Parametric modeling removes this duplication of work. Parametric modeling allows for the automatic updating of the whole design. If you edited that one mechanism using parametric modeling, the whole design would automatically update to reflect the change. Obviously, this is a superb time-saver. It means that you can easily make changes to your work without a detriment to your workflow.

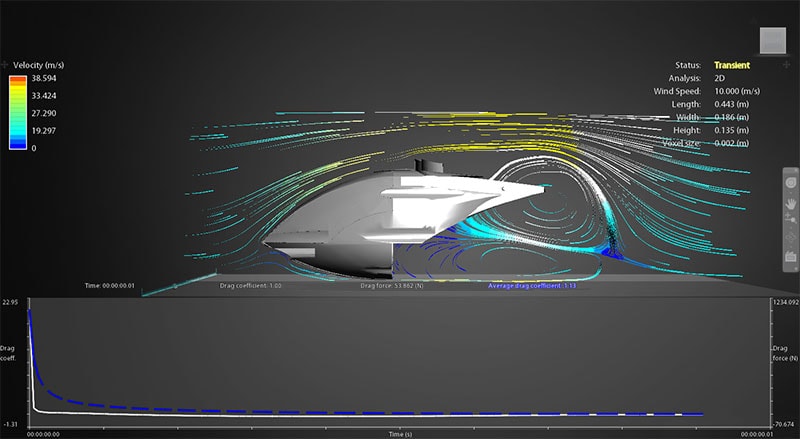

Pre-Prototype Simulation to Reduce Errors

Simulation is a vital aspect of the CAD design industry. The ability to design a product or object is one skill. Ensuring that design can be translated into a working product is another. This is why simulation is key. The ability to create complex simulations with your CAD designs greatly improves the whole process. It can also reduce costs and time wasted.

If we look at an example – you have designed a new hand tool. In principle, the internal mechanics within the tool should work. You come to create and test a prototype, however, and the tool jams and can’t perform its primary function. As a result, you have to spend time re-creating the design and working with a prototype design service – this is obviously expensive and time-consuming.

Having built-in simulation capabilities within your design software would eliminate these issues. You could test the product within the software without ever having to create a prototype. Once you were satisfied with the simulations, and the product was working as intended, a prototype could then be created. Only certain robust CAD programs have simulation capabilities.

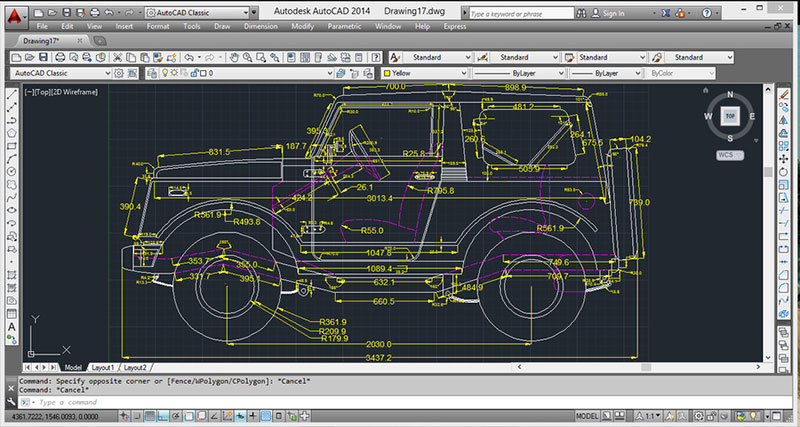

Ability to Work within a Multi-CAD Setup

When working within the CAD industry, your design team may have to cooperate with other companies. What happens if that company uses different CAD software? How would you be able to view and edit their designs and integrate them into your own systems?

This is why a multi-CAD setup is beneficial. Advanced CAD software often has multi-CAD capabilities. This means that one CAD program can be used in conjunction with a myriad of other programs and tools. It could use non-proprietary file formats such as STEP. Furthermore, it may accept plugins that extend its functionality.

Improved Integration between Teams

Interdepartmental cooperation is essential in today’s CAD industry. Ideally, a CAD design program should be usable at every stage of your business. Each team should be able to use the CAD program for their own purposes, and seamlessly pass on their work to the next section. This improves the workflow and ensures continuity within the design process. It can also reduce costs due to a decreased need for different software licenses.

Using limited CAD software, your team may not be able to cooperate effectively. Different departments, for example, could have to use different software. This is obviously ineffective and time-consuming. Each department would have to spend time ensuring their work is formatted correctly ready for the next team to use. Check that the CAD software has a diverse range of functions – look at how it could be used within your business. Robust CAD programs usually have a myriad of functions for cross-department usage.

Succinct Workflow Using Top-Down Modeling

In certain circumstances, members of your team may have to work on the same project concurrently. This, of course, can be hugely confusing. It can also lead to errors and miscommunication. If one person makes a change, for example, how can another person working on the design see that change in real-time?

Basic CAD programs will have no such functionality – they may even be limited to one person working on a project at any one time. This can greatly reduce your effectiveness. It can also slow down the design process.

Robust CAD software can have top-down modeling capabilities. As a business, you can set rules and procedures for concurrent editing. Moreover, your team could cooperatively work on designs in a non-destructive manner with updates in real-time.

Improved Communication with Customers and Third-Party Businesses

Communication is key in modern business. We now have a myriad of digital mediums that enable quick and effective communication. In the CAD design industry, communication between designers and clients has historically been difficult. Showcasing your ideas to clients can be tricky – especially if you are using proprietary files or a program that doesn’t allow document sharing.

This is why a robust CAD program can pay dividends. Some CAD programs use only proprietary file types – this would mean that your end-customer has to have the same software installed to view the design. Obviously, your customer may not want to incur costs such as these just to view their products!

Other CAD programs, however, use vendor-neutral or non-proprietary file types. Generic file types such as these may not be tied to one specific platform. This means that your customers could access them easier using standard viewing software. Furthermore, some CAD software has cloud functionality and the ability for both the customer and designers to work cooperatively on projects.

Hopefully, you now have greater insight into CAD software choice. Don’t settle for less! Cheap software is not always the right option. You must carefully weigh up your business needs. Create a detailed plan of your requirements including future scope. Furthermore, research the different type of CAD software available and ensure that the program you choose is robust.

Cad Crowd’s Design Professionals Are Experts in Every Software

At Cad Crowd, we have the honor of working with some of the best CAD design and 3D modeling freelancers around the globe. Our team has experience working on all type of projects, regardless of scope. Find out how it works today.