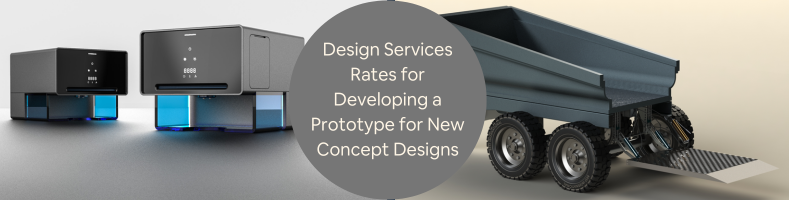

The post for today discusses design services rates for developing a prototype of your firm’s new product concept design. But why do you even need a prototype in the first place? Some need prototypes in the hopes of proving their product’s new technical features. Others may want to develop a prototype for their Kickstarter or GoFundMe campaign. And then, there are those who wish to make a prototype for testing the product and whether it has a spot in the market or not. Alas, there are many aspects to prototype design services.

However, the moment you get all the answers, you’ll notice that all of them share one thing in common. That’s none other than risk. The main purpose of a prototype is to evaluate, qualify, and reduce design risk as much as possible. This risk can take on many forms, which include manufacturing, technical, business, and user risk. As expected, a one-off prototype will cost more if the risk involved is also bigger.

Cad Crowd is the leading agency that can help you connect with experts providing prototypes for your firm. Consisting of over 94,000 freelancers, we pride ourselves on our ability to give reasonable service rates while still exceeding your highest standards. Whether you’re looking for innovative solutions, new concept design, strategic insights, or top-tier execution, Cad Crowd has the expertise and the talent to bring your vision to life.

🚀 Table of contents

Prototype development at a glance

The prototype development stage in the process of creating a product starts with a unique design idea. This idea is a representation of a descriptive state in a verbal or written form. The idea then undergoes polishing into a product concept that will include the benefits and features of the product.

The same concept then gets developed into a prototype to represent the working model, including its size. The prototype becomes the final product after a number of repetitions. Prototypes come in different types, and the initial stage is used for verifying the content’s form.

Following the validation stage, the next step is the pre-production before the development of the final version for new product concept design services. This one is almost the same as the completed product, which includes the appearance, packaging, and instructions. However, the final prototype can be quite costly, ranging between $3,000 and $10,000.

RELATED: 6 industries revolutionized by 3D rendering freelancers & design services companies

How much should you expect to spend for your prototype, then?

To determine how much it would cost you to develop a prototype for the new product concept design of your firm, it’s imperative that you know exactly where you are already in your journey on product development. You can do this by following the product development process.

Below are the four stages involved in prototyping. Take a moment to review the different types of prototypes and the risk identification at every stage.

1st stage: concept design starts at $1,000

This particular stage in prototype development services focuses on user and chooser prototypes for product research. These prototypes simulate user experience with adequate fidelity to give third parties a chance to comment on the new product and its value.

Some of the risks identified in this stage include the following:

- Determine the device’s constraints in terms of physical size.

- Methods of interaction and the handiest solution.

- Risk of device rejection or user confusion.

The most common types of prototypes used for this stage include:

- Foam models

- User interface mock-ups

- Virtual 3D renderings and wireframes

- Wizard of Oz functionality or beauty models

The cost and design time of prototypes may also vary. The overall design time may be a week or less, and the design costs for the preliminary mock-ups and sketching can start at $1,000. Materials are mainly off-the-shelf, including 3D custom prototype parts, tape, canned software, glue, module electronics, and cardboard paper.

RELATED: How cutting-edge medical prototyping design services help your firm design new products

2nd stage: design engineering starts at $5,000

Prototype design engineering services focus on the bench model engineering prototypes that quantify the choices for making important decisions regarding the design.

Some of the identified risks at this point include:

- Functionality of the mechanism

- Test specific parts of the design

- Risks of structural, stress, fluid, and thermal engineering

- Management of wires and sub-components

- Limitations of wireless protocol

This stage uses two main types of prototypes:

- Proof of concept or hand-built models

- Product’s scale models

The costs involved are medium and depend on the validation metrics for user testing and the required customized sub-systems. The starting estimate for the bench model prototyping testing and the costs of materials is $5,000.

3rd stage: prototype and test costing $10,000 and higher

The third stage outputs a fully functional production alpha prototype. However, it also involves several identified risks, such as:

- Risk for the business and the cost of the components and parts in volume

- Risk for the business in terms of high volume and yield outputs

- Wireless connectivity and custom electronics

As mentioned earlier, alpha prototypes that are fully functional are used at this point. In terms of costs, the stage has a medium price range, which depends on the output volume and product complexity. The average time for development is at least four to six weeks. The costs of the alpha prototype material range from several hundred to thousands. It depends on the required fidelity, electronics, and custom parts.

4th stage: manufacturing set-up and ready for production at $30,000

The last stage is the production of parts in a prototype that is ready for manufacturing design services. It is basically a fully manufactured early-stage unit. There are two identified risks involved here. First is the business risk related to the lead time of the parts, assembly, and components. Second is the risk in the manufacturing process, which includes wall thickness of the parts, color matching, and surface finish, just to name a few.

Early small runs of pilot pre-production units are used in this stage. The costs involved are medium, which depend on the volume of output and the complexity of the product. The development time can run for at least three months.

The costs often start at $30,000 for the basic products, and it can go higher depending on the development time, volume, and manufacturing process involved.

Challenges involved in estimating the costs of prototype development

The latest research has revealed three significant hindrances involved in estimating the costs of developing a prototype for a new product. These challenges include the following:

- Fluctuations in the costs of raw materials

Even though it may have no effect on some products, you might want to be more strategic here during the conceptualization and design stage. The main idea here is to opt for materials whose market prices are less volatile and then invest in the said items.

- Lack of complete perspective

The shortage of a complete perspective has something to do with taking a look at the bigger picture during the project’s early stage and then rolling out all the costs without even understanding the entire process, including the costs for prototyping designers. It results in the evaluation of the costs throughout every stage of the prototype development and placing in the data to affect the earlier estimations.

- Spending time to understand the cost

Most of the time, decisions are just held up rather than being taken at the soonest time possible. A designer, for example, might be interested in knowing if you will be using aluminum or magnesium to finalize the model. However, having loads of calculations for doing that might result in the project being held up. But things will be so much faster if you plan and try to understand the entire variable cost as early as you can.

Being familiar with these challenges and taking advantage of them in determining the estimated costs of prototype development can serve as your guide in choosing the appropriate material you should use that best suits your project.

What about the fixed costs, though? For industrial design jobs, this will come with a few fixed costs as compared to someone willing enough to pin their idea. A fixed cost is literally a payment that you pay that won’t change at all, no matter the external factors involved. It doesn’t really matter at which stage you are in the production process because the cost will still remain the same.

RELATED: How much does NPD cost? Rates & pricing for services at top design companies

Factors that affect prototyping costs

Several factors affect the cost of prototyping. Each factor has a different effect on the total price and must be taken into consideration.

- Choice of materials

The chosen materials determine the cost of the prototype development. The cost of raw materials is not dependent on the specific tools used. If the material is of higher quality, it will also cost more, as expected.

- Complexity of the design

The complexity of the design also has a direct impact on the costs of the prototype. If the prototype has a more straightforward design, for example, its cost will be lower than that of one that is more complicated. If you need rapid prototype services, it will add to the costs, especially for more complex designs. The idea here is that a simple geometry will be easier to produce than its complex counterpart.

- Cost of labor

The cost of labor may also differ depending on the workers’ geographical location. The labor rates also differ depending on the country. There might also be hidden charges that you’re unaware of during the prototyping.

When complex parts are being produced, it’s a must to hire professional and highly skilled technicians who can add more value to the prototype and the product afterward. The level of skill and experience has a significant influence on the cost of the prototype development.

- Tolerance

The prototype’s level of tolerance is another important factor. What kind of accuracy do you like the product or prototype to have?

RELATED: Using 3D visualization services to communicate design intent to clients and firms

Conclusion

Turning your concept design into a prototype might surprise your fixed expenses, especially if you’re new to the industry. However, it can still be avoided by doing thorough research about it. A simple awareness regarding the prototype process and stages your design needs to undergo is important to carefully plan your budget. Also, knowing what your final product is like in terms of choice of material and detailed functionality and design will speed up the process of prototyping and, therefore, will lessen the cost.

How Cad Crowd can help

Cad Crowd will help ensure that the whole process of prototyping will be smooth and seamless. We will connect you with an experienced prototyping team that can bring your product to life. Schedule a consultation with us to talk about your project and embark on your journey to successfully developing your prototype and launching your new product. Get a quote today!