I offer automotive wheel design engineering & OEM-level validation services

About this service

I deliver complete automotive wheel (rim) design engineering, covering the full development cycle - from early design and CAS, through Class-A surfacing, engineering coordination, supplier CAD refinement, and final OEM-level polishing and validation.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

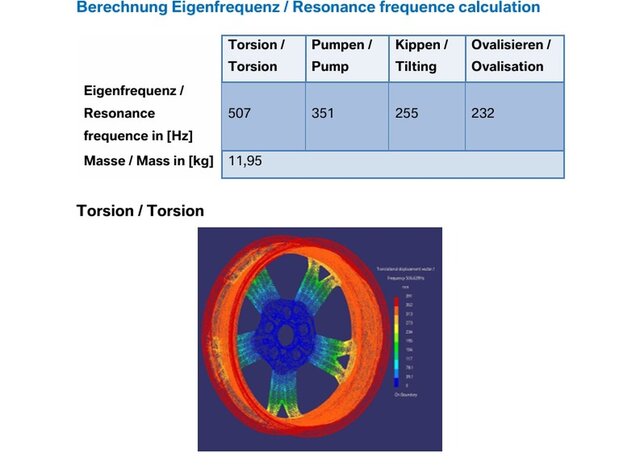

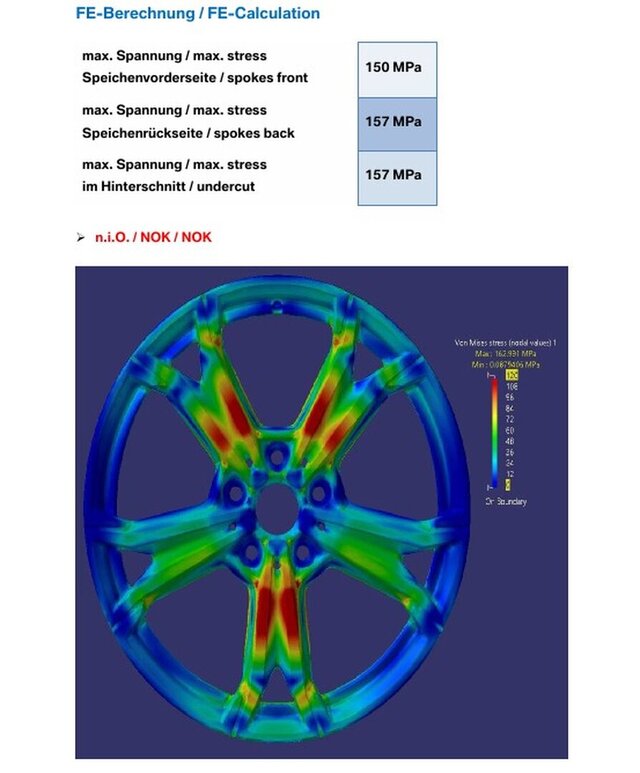

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling.

I deliver complete automotive wheel (rim) design engineering, covering the full development cycle - from early design and CAS, through Class-A surfacing, engineering coordination, supplier CAD refinement, and final OEM-level polishing and validation.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling.

I deliver complete automotive wheel (rim) design engineering, covering the full development cycle - from early design and CAS, through Class-A surfacing, engineering coordination, supplier CAD refinement, and final OEM-level polishing and validation.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation prot... read more

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation prot... read more

I deliver complete automotive wheel (rim) design engineering, covering the full development cycle - from early design and CAS, through Class-A surfacing, engineering coordination, supplier CAD refinement, and final OEM-level polishing and validation.

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling. read less

My experience is built on real production wheel programs for BMW, where wheel development is governed by strict internal guidelines, validation protocols, and cross-disciplinary sign-off processes.

I work at the intersection of design, engineering, manufacturing, and validation, ensuring that wheels are not only visually refined, but also structurally correct, manufacturable, aerodynamically considered, and compliant with OEM expectations.

This includes involvement in wheel FEA interpretation, brake cooling and airflow considerations, crash behavior awareness, and supplier data correction during late development stages.

This service is intended for OEMs, Tier-1/Tier-2 suppliers, performance-vehicle programs, and special-purpose or military applications requiring production-ready wheel solutions—not conceptual styling. read less

Service offer categories

Automotive Design

3D Design Services

FEA Finite Element Analysis

Software & skills

Autodesk Alias Surface

Automotive Design

Automotive Engineering

Class-A Surfacing

Manufacturing

+2 more

This service includes

| Service tiers | Simple $500 | Standard $1,000 | Advanced $1,500 |

|---|---|---|---|

| Summary | Wheel Design Review & Engineering Feasibility | Wheel Design Engineering & Class-A Refinement | OEM-Level Wheel Engineering |

| Details | Expert review of an existing wheel concept or CAD from a design-engineering perspective. Includes evaluation of visual logic, manufacturability constraints, brake clearance awareness, and early engineering risks. Ideal for early-stage validation or informed go/no-go decisions before deeper development. | Hands-on wheel design engineering including CAS/polymodeling cleanup and Class-A surfacing. Focus on manufacturable geometry, visual quality, brake integration, and production-ready CAD refinement aligned with OEM expectations. | Comprehensive wheel design engineering up to OEM sign-off readiness. Includes final Class-A polishing of supplier CAD, FEA-aware geometry iteration, manufacturing and finishing compliance, brake cooling considerations, and validation against strict OEM internal guidelines. |

| Delivery time | 3 days | 7 days | 14 days |

| Number of revisions | 0 | 1 | 2 |

★ 5.0 (1)

Top designer

Top designer

Gothenburg, Gotlands Lan, Sweden – 11:34 p.m. local time

Member since

January 2019

Languages

English,

Serbian,

Croatian,

English,

German

Avg. response time

1 hour

Senior CAD & Class-A Surfacing Engineer | Aerospace, Defense & High-End Manufacturing

I am a senior mechanical design engineer specializing in complex, high-end products where industrial design, engineering, and manufacturability must work together. My background spans aerospace systems, advanced consumer products, and automotive-grade surfacing, with a strong focus on turning concepts into production-ready geometry.

I work across the full product development cycle — from early co... read more

I work across the full product development cycle — from early co... read more

Questions and answers

Both. I can develop wheels from early concepts or take over existing designs — including late-stage supplier CAD — for engineering refinement, Class-A surfacing, and OEM-level polishing.

No. Wheel design cannot be separated from engineering. My work includes structural awareness, FEA-driven geometry iteration, manufacturing constraints, brake clearance, cooling airflow considerations, and validation logic.

Yes. Refining and correcting supplier CAD to meet OEM visual and geometric standards is a core part of my work.

Yes. I work against strict internal OEM wheel development guidelines and validation processes, similar to those used in major automotive OEM programs.

I collaborate closely with CAE teams, interpret FEA results from a design perspective, and adjust geometry accordingly. I focus on balancing stiffness, mass, fatigue behavior, and compliance.

Yes. Wheels must be strong, but not excessively stiff. I am familiar with controlled deformation requirements and failure mode considerations during crash scenarios.

Absolutely. Most wheel projects are NDA-protected.

Cad Crowd Billing Security policy

Service quality is protected by Cad Crowd Billing Security policy.

More from Rade C.

More similar services

See related services

- 3D Design services

- 3D Modeling services

- CAD Design services

- 2D & 3D Design services

- 3D CAD Design services

- 2D & 3D Modeling services

- CAD Modeling services

- 2D & 3D CAD Design services

- Drafting services

- Engineering Design services

- AutoCAD services

- Product Design services

- Rendering services

- 3D Models services

- Mechanical Design services

- 2D Drafting services

- 3D Rendering services

- 2D Drawing services

- Mechanical 3D Design services

- Design for Manufacturing services

- 2D AutoCAD services

- Architectural Design services

- SolidWorks services

- 3D Solidworks services

- 2D & 3D Drafting services

- Mechanical Engineering services

- 2D/3D AutoCAD services

- 2D & 3D Modeling Solidworks services

- Concept Design services

- Assembly Design services

- Interior Design services

- Industrial Design services

- CAD Assembly services

- Design Engineer services

- FEA services

- Mechanical Engineer services