I offer hydraulic systems design and engineering services

About this service

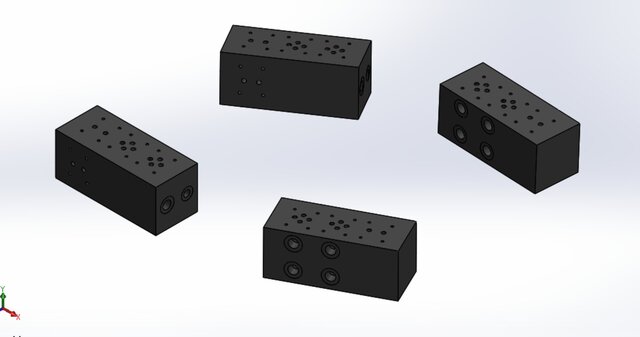

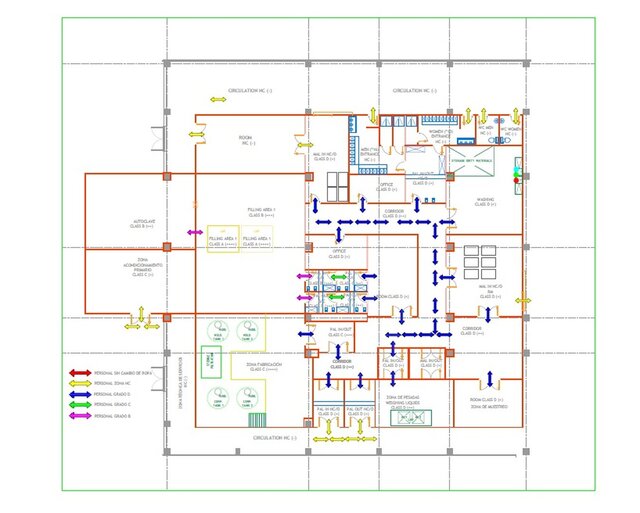

Conceptual and Detailed Design: The ability to convert your specifications into detailed 3D models and 2D manufacturing drawings utilizing industry-standard software like as SolidWorks, AutoCAD.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

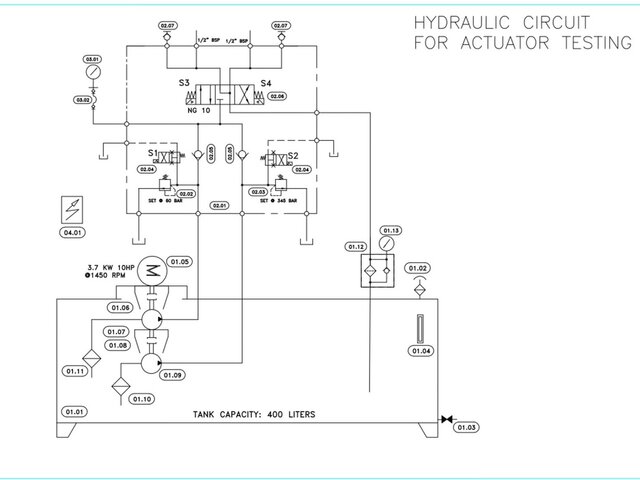

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications.

Conceptual and Detailed Design: The ability to convert your specifications into detailed 3D models and 2D manufacturing drawings utilizing industry-standard software like as SolidWorks, AutoCAD.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications.

Conceptual and Detailed Design: The ability to convert your specifications into detailed 3D models and 2D manufacturing drawings utilizing industry-standard software like as SolidWorks, AutoCAD.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria... read more

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria... read more

Conceptual and Detailed Design: The ability to convert your specifications into detailed 3D models and 2D manufacturing drawings utilizing industry-standard software like as SolidWorks, AutoCAD.

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications. read less

System and Component Sizing: Proficiency in performing the necessary calculations to accurately size hydraulic pumps, motors, cylinders, valves, and accumulators to meet your specific performance criteria.

Hydraulic Circuit Design: A deep understanding of creating efficient and reliable hydraulic circuits, including open-loop, closed-loop, and load-sensing systems.

Actuator Design and Selection: Expertise in designing and selecting the optimal linear or rotary actuator for your application, considering factors such as force, speed, and environmental conditions.

Material and Component Selection: A thorough knowledge of materials and components suitable for hydraulic systems, ensuring longevity and reliability.

Simulation and Analysis: Experience with simulation software to analyze system performance, identify potential issues, and optimize designs before manufacturing.

Prototyping and Testing Support: The ability to provide guidance and support during the prototyping and testing phases to ensure the final product meets all specifications. read less

Service offer categories

Mechanical Design Services

SolidWorks Design Services

AutoCAD Design Services

Software & skills

2D Drawings

2D/ 3D Solidworks

Actuator Design

AutoCAD

Automation Studio

Material Selection

Simulation

Testing

+5 more

This service includes

| Service tiers | Simple $125 | Standard $250 | Advanced $750 |

|---|---|---|---|

| Summary | Basic Hydraulic Circuit Concept | Detailed Hydraulic Circuit Design | Production-Ready Hydraulic System |

| Details | Functional hydraulic schematic (ISO symbols) Basic component selection (pump, valves, cylinder, tank) Flow direction & logic explanation Operating pressure and flow assumptions | Fully calculated hydraulic circuit Cylinder sizing & force calculation Pump flow and motor power calculation Pressure loss estimation Relief valve, flow control & safety logic | Final hydraulic circuit with all safety & service features Manifold logic or piping layout concept Port sizes, hose & fitting selection Bill of Materials (BOM) Installation & commissioning notes Design review support |

| Delivery time | 2 days | 4 days | 7 days |

| Number of revisions | 2 | 3 | 4 |

Member since

December 2025

Languages

Telugu,

Kannada,

Hindi,

English

Avg. response time

1 hour

Hydraulic Systems and Actuator Design Specialist

I’m a Mechanical & Hydraulic Design Engineer with 4+ years of hands-on experience in hydraulic systems, cylinders, power packs, manifolds, and industrial machinery. I specialize in calculation-driven design, clear documentation, and production-ready drawings that installers and manufacturers can trust.

I’ve helped clients with:

Hydraulic circuit design & validation

Cylinder & actuator design (cal... read more

I’ve helped clients with:

Hydraulic circuit design & validation

Cylinder & actuator design (cal... read more

Questions and answers

calculate cylinder size based on required force, available system pressure, and safety factor. Load calculations include static load, dynamic forces, friction, and shock factors. I then verify buckling (for long strokes), rod strength, seal pressure limits, and duty cycle to ensure reliability and long service life.

design according to widely accepted standards such as ISO, DIN, and SAE. My approach emphasizes correct pressure ratings, proper sealing methods, contamination control, fail-safe logic, and maintainability. All designs are focused on manufacturability and real-world operating conditions, not just theoretical layouts.

I minimize losses by correctly sizing pipes and hoses, selecting valves with appropriate flow coefficients, avoiding unnecessary restrictions, and optimizing circuit layout. Heat generation is controlled by efficient pump selection, correct relief valve settings, and proper return-line design to maintain oil temperature within safe limits.

Yes. I convert hydraulic schematics into clear 2D manufacturing drawings and 3D CAD models, including manifolds, mounting details, and assemblies. I also provide a structured Bill of Materials with component specifications, pressure ratings, seal types, and part descriptions suitable for procurement and fabrication.

I diagnose issues by analyzing flow paths, suction conditions, pressure drops, valve behavior, and system feedback. Common causes such as undersized lines, air ingress, incorrect valve settings, or pump mismatch are identified and corrected through design improvements rather than temporary fixes.

Cad Crowd Billing Security policy

Service quality is protected by Cad Crowd Billing Security policy.

More similar services

See related services

- 3D Design services

- 3D Modeling services

- CAD Design services

- 2D & 3D Design services

- 2D & 3D Modeling services

- CAD Modeling services

- 2D & 3D CAD Design services

- Drafting services

- Engineering Design services

- Product Design services

- AutoCAD services

- CAD Drafting services

- Rendering services

- Mechanical Design services

- 2D Drafting services

- 3D Models services

- 3D Rendering services

- 2D Drawing services

- 3D Mechanical Design services

- Mechanical 3D Design services

- 2D AutoCAD services

- Architectural Design services

- SolidWorks services

- 3D Solidworks services

- 2D & 3D Drafting services

- 2D & 3D Mechanical Design services

- Mechanical Engineering services

- 2D/3D AutoCAD services

- 2D & 3D Modeling Solidworks services

- Floor Plans services

- Assembly Design services

- Interior Design services

- Industrial Design services

- FEA services

- Mechanical Engineer services

- Design Engineer services