Gridseed Scrypt ASIC Mining Frame - Acrylic Waterjet & CNC

in

Electronic Devices

held by

Billy Nare

Last seen:

Contest Ended, Winner(s) have been selected.

-

Open

-

Choosing Finalist

-

Ended

Description:

Howdy!Let's do something futuristic.

Cryptocurrency mining, heard of it? There's specialty computer hardware used to hash mathematical algorithms in a distributed network to generate digital money!

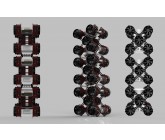

This project is to build a frame to sexily mount 10 of these specialty computers to in hopes of cleaning up some messy mining rigs out there.

Speaking of messy rigs, here's a video of some good and some bad examples of the Gridseed ASIC miners. www.youtube.com/watch

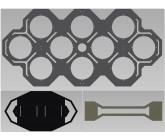

In the attached image TheDrawingBoard.jpg you'll see some ideas but I welcome your own input if you believe you've got something that equals win.

Ask questions, let's do this!

Wants:

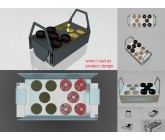

The Gridseed miners measure 95mm in diameter and 70mm tall, so roughly 3.75" D x 2.75" H. I will have mine in hand within a couple weeks, they're just now coming out of China, then I will know the distance between the mounting holes to secure them to the frame.The power supplies on the lower level of the frame measure (215 x 115 x 50)mm / (8.46 x 4.52 x 1.96)inch(L x W x H)eBay link for more images; www.ebay.com/itm/SUPERNIGHT-12V-DC-30A-360W-Regulated-Switching-Power-Supply-for-LED-Strip-Light-/261401107652

The USB Hub measures 190 x 58 x 28mm, eBay link; www.ebay.com/itm/USB-2-0-10-Port-Powered-Portable-HighSpeed-External-Hub-Multi-Outlet-Power-Strip-/200994217600

Let's keep the top plate of the frame within 24" L x 12" W x 0.25" thick acrylic sheet.

The lower frame just needs to be slightlu larger than the power supplies that will sit on it.

The CNC Aluminum struts to separate it should work well in the 3-4" range.

Don't Wants:

Put extra mayo on my McChicken sandwich at McDonald's next time, that's some shit I don't like.

Software:

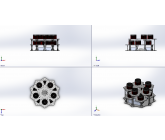

- Autodesk Inventor

- SolidWorks

Additional Information

Please make all future submissions from flat parts only. This includes the struts.Laser cutting will be used.

0.0625 inch/1.5875 mm thick aluminum for the mounting plates. 0.25 inch/6.35mm thick aluminum for the separating struts.

Detail, futuristic design and stackable are desired traits in new submissions.

Thanks!

Entries

1st Winner

#24 Edit

by Sergiu.Nasta

Download Files

2nd Winner

#27 Gridseed Scrypt ASIC Mining Frame - Acrylic Waterjet & CNC

by Ovi

Download Files

3rd Winner

#23 Gridseed_8

by jnatzic

Download Files

#9 Frame

by Sergiu.Nasta

#11 _ASIC Minning Frame

by Ovi

#14 Frame

by Sergiu.Nasta

#26 Gridseed Scrypt ASIC Mining Frame V02

by CAD SPARKLES

#21 frame

by Sergiu.Nasta

#20 Frame

by Sergiu.Nasta

Download Files

#17 Gridseed_7

by jnatzic

Download Files

#16 Gridseed_6

by jnatzic

Download Files

#15 Gridseed_5

by jnatzic

Download Files

#13 Frame

by Sergiu.Nasta

Download Files

#10 Gridseed_4

by jnatzic

Download Files

#8 _ASIC Minning Frame

by Ovi

Download Files

#4 Gridseed_3

by jnatzic

Download Files

#2 Gridseed_2

by jnatzic

Download Files

#1 Gridseed_1

by jnatzic

Download Files

#12 bandeja

by N.J.Brizuela

Download Files

#7 _ASIC Minning Frame

by Ovi

Download Files

#6 _ASIC Minning Frame

by Ovi

Download Files

#22 BTC miner rig tower

by asdfasf

Download Files

#5 _ASCI Minning Frame

by Ovi

#25 Gridseed Scrypt ASIC Mining Frame

by CAD SPARKLES

#3 Support

by jnatzic

Download Files

Discussion

Showing last 20 comments - View All

rig for gridseed very efficient and tidy.

God forbid the place on to stick the usb hub and its controller gridseed and it would be a compact stand alone. really well done.

I really like the version of Rhinoceros 5 - Version 1.

I wish I could do on my gridseed. you can also download the file to dwg?

God forbid the place on to stick the usb hub and its controller gridseed and it would be a compact stand alone. really well done.

I really like the version of Rhinoceros 5 - Version 1.

I wish I could do on my gridseed. you can also download the file to dwg?

Number 23, 24 and 27 - you guys are the winners. Thanks for your hard work, I will be in contact through PM to finalize any last details of the design as I begin to work closely with the laser cutting facility this week.

You 3 wont have to argue about 1st, 2nd or 3rd places either - they're worth $200 each to me even if they wont all be mass produced.

You 3 wont have to argue about 1st, 2nd or 3rd places either - they're worth $200 each to me even if they wont all be mass produced.

UPDATE: Hardware in hand! See file attachment meas.jpg for product measurements and get those designs updated!

The files look great, thanks for the simplification. (He attached an older render, but simplified the frame design, in case you're wondering.)

The files look great, thanks for the simplification. (He attached an older render, but simplified the frame design, in case you're wondering.)I am going to get a quote on these parts. The number of "features", as the shop puts it, is lower so we will see.

Thanks!

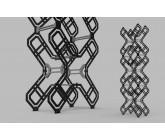

I like this because the flat side can face the wall and hide a lot of the cables nobody wants to see.

I like this because the flat side can face the wall and hide a lot of the cables nobody wants to see.As described in PM the usage of the thicker aluminum would make it more expensive. Perhaps in future projects we will go for a higher price for mounting 50-100 miners to a single frame and could afford the stronger materials.

Thanks again for your creativity on the project!

ATTENTION DESIGNERS:

I spoke with the shop that will produce the laser cut parts today and here's what he had to say when comparing submission 2/4 with submission 17:

"I took a look at the new top and although it looks more simple it would actually be about the same cost.

We quote laser cutting based on the number of pierces and the linear cutting inches. Each time the laser has to get through the material it can take 3-30 seconds depending on material type and thickness.

The original .dxf had approximately 60 features and 400 linear inches of cutting. The revised .dxf had around 70 features and 325 linear inches of cutting. The changes basically cancelled each other out and the revised .dxf would actually take just slightly longer to cut.

The revised .dxf is positive in that it may make sense to move these to a CNC Turret Punch. This type of machine runs at a lower rate and might work for the parts out of .060 aluminum."

The current goal is to cut the costs down. Submission 2/4 would be close to $60 before tapping the struts for mounting holes and plating the metal to look cool. I'd like to get each frame produced for $50 including the strut mounts and plating.

I spoke with the shop that will produce the laser cut parts today and here's what he had to say when comparing submission 2/4 with submission 17:

"I took a look at the new top and although it looks more simple it would actually be about the same cost.

We quote laser cutting based on the number of pierces and the linear cutting inches. Each time the laser has to get through the material it can take 3-30 seconds depending on material type and thickness.

The original .dxf had approximately 60 features and 400 linear inches of cutting. The revised .dxf had around 70 features and 325 linear inches of cutting. The changes basically cancelled each other out and the revised .dxf would actually take just slightly longer to cut.

The revised .dxf is positive in that it may make sense to move these to a CNC Turret Punch. This type of machine runs at a lower rate and might work for the parts out of .060 aluminum."

The current goal is to cut the costs down. Submission 2/4 would be close to $60 before tapping the struts for mounting holes and plating the metal to look cool. I'd like to get each frame produced for $50 including the strut mounts and plating.

I love it and hope it fits within the target budget, will get a quote on the parts this week and update you then.

I love it and hope it fits within the target budget, will get a quote on the parts this week and update you then.Thanks!

Thanks for your revisions. That should hit the target price point with the simplifications.

Thanks for your revisions. That should hit the target price point with the simplifications.  XXX Porno, super hot mining rig stack.

XXX Porno, super hot mining rig stack.  Brilliant, compact design that I am liking a lot!

Brilliant, compact design that I am liking a lot!Thanks for coming up with that new design. It's much more do-able.

Thanks for your submission.

Thanks for your submission.I feel it is too simple in design, but I do like how you made everything work off a single piece of metal. That would obviously cut costs down a lot.

More detail, futuristic design and stackable are desired traits in new submissions. Number 11 is a great reference point.

Nicolas, we do have time for additional submissions. Thanks for your interest.

Our current target for materials is 0.0625 inch/1.5875 mm thick aluminum for the mounting plates. 0.25 inch/6.35mm thick aluminum for the separating struts.

All flat parts that can be cut on a laser cutter. I will have the struts finished at the cnc shop for mounting holes.

Thanks

Our current target for materials is 0.0625 inch/1.5875 mm thick aluminum for the mounting plates. 0.25 inch/6.35mm thick aluminum for the separating struts.

All flat parts that can be cut on a laser cutter. I will have the struts finished at the cnc shop for mounting holes.

Thanks

Billy;

I'm Nicolas; from www.i-cad.es

got time for another idea?

best regards

I'm Nicolas; from www.i-cad.es

got time for another idea?

best regards

This is an interesting concept.

This is an interesting concept.Don't you agree that the middle plate supporting the weight of the upper plates would be under stress and bend?

I sent the files for you submission number 4 to several different laser cutting facilities today, still waiting on a quote from the waterjet place I had in mind. Laser cutting looks so much faster and cleaner though, should be cheaper too. So we'll probably go with that for the winning designs.

UPDATE: 7.25cm distance between screw holes for mounting the miners.

I received an update today from China. This is a video of the production miners in action: https://www.youtube.com/watch?v=fyd992JqnjI

The miner design seems to be the same, but the heatsink color has changed to Gold. I was told 5.1cm distance between the screw points on the fan/heatsink, let me know if this is not looking right when modeled and I will ask for another measurement.

Thanks guys, I hope we can clean up a lot of ugly desktops like that in the video and have them looking as advanced as the currency they're mining.

The miner design seems to be the same, but the heatsink color has changed to Gold. I was told 5.1cm distance between the screw points on the fan/heatsink, let me know if this is not looking right when modeled and I will ask for another measurement.

Thanks guys, I hope we can clean up a lot of ugly desktops like that in the video and have them looking as advanced as the currency they're mining.

Amazing!

Amazing! It looks like this competition will run a while longer and I will be adding 2nd and 3rd place prizes because it will be difficult to settle one a single design!

Very nice, thanks for the adjustments.

Very nice, thanks for the adjustments.  Thanks a lot for your timely revisions. I really have no issues with anything now.

Thanks a lot for your timely revisions. I really have no issues with anything now.Let's see what the waterjet company says in the next few days for a quote. Hoping it'll be perfect with the amount of detail packed into the design, but might have to do some slight simplification to meet a price point. Retail's gotta be below $100 or it'll be a tough sell.

OMFG!

OMFG!You dudes have your work cut out for you now, jnatzic set us up the FUTURE, on that one.

Mining in style!

Thanks so much for your work dude.

Similar Contests on Cad Crowd

Mini-ITX Computer Case

Hi Everyone!

This contest is for the smallest Mini-ITX computer case with the following requirements:

-Includes rendering of a mini-itx motherboard

-Includes rendering of two nvidia 1080 video card in sli configuration

-Enough room for liquid cooling on cpu and video cards including radiator fan(internal or external).

-Includes rendering of 800watt SFX-L PSU

Klein two way radio

We are going to make a new housing / face design for our two-way radios (walkie talkies). Must be professional, not a kids-toy design. Something rugged, ergonomic, and aesthetically pleasing.

Panic Button with logo

Denis, we need your help urgently. The lighting is not working for us on the light silver shell and it's coming out really dark on our end. Can you please create a render for us where you swap out the exclamation point with this logo? And show it in a variety of colors? Here are the instructions:

1. Swap out exclamation point with this logo

2. Show it in a variety of colors - maybe 4 or 5 logo colors. Please keep the logo treatment the same as this exclamation point treatment. Nothing should be different except the exclamation point becomes this logo.

3. Shell color is the light silver shell.

4. I have attached the logo file plus a mock of what we're looking to achieve.

5. One render where it is closed as well where you can see “armed” light

6. Timeline: tonight. Is this possible? We need it for a meeting tomorrow morning PST.

A schematic development of a 100W (4-port) GaN charger

We require a full Circuit Design (Schematic) development of a 100W (4-port) GaN charger. What's expected:

-Circuit Design

-BOM (list of components)

Project information:

Technology:

GaN

Input:

100-240V~50/60Hz 2.3A Max

Output power distribution:

USB-C1/C2/C3: 5V/3A 9V/3A 12V/3A 15V/3A 20V/5A 100W Max

USB-A: 4.5V/5A 5V/4.5A 5V/3A 9V/2A 12V/1.5A 22.5 Max

Total Output:

100-122.5W Max will be effectively distributed across all active ports

Protocols:

* USB C Ports: PD3.0(PD2.0) /QC5+(QC5.0\QC4.0\QC3.0\QC2.0)/PPS /AFC/APPLE 5V2.4A/BC1.2

* USB A Port: SCP/QC3.0/AFC/FCP/APPLE 5V2.4A/BC1.2

Dimensions:

Length: 80mm

Width: 45mm

Height/Thickness: 35mm

Safety requirements:

Input over-voltage protection:

* Output over-current

* Over-voltage

* Short circuit protection

Thermal protection:

* Over-heat protection

Total cost of all components in one charger:

A single charger’s components should not cost more than $20-$35 in total, if we use the “1000-pieces” unit price of the components.

Design 2018's best selling adult product

We are a manufacture in the adult market, specialising in creating new and unique product collections for our branded customers.

Because of the new acceptance of our products, we are looking for some new and unique idea's to launch for the mainstream market. They are still used by adults for adult reasons, but with a 2018 design lead feel.

I would like you to design a new product, a Rabbit, or a vibe, handheld personal massager, couples love ring...

Prepaid Prize

Prepaid Prize

gelmo74