3D printable mount to turn 'tiny whoop' drone parts (+paper) into a remote control paper airplane with FPV

in 3D Printing Design held by Drone Bites ManDiscussion

FLIGHT VIDEO OF THE WINNING DESIGN. (design  ) Congratulations! https://youtu.be/iMGbn0osrTA

) Congratulations! https://youtu.be/iMGbn0osrTA

) Congratulations! https://youtu.be/iMGbn0osrTA

) Congratulations! https://youtu.be/iMGbn0osrTA

FIRST PLACE:  (and

(and  ) by Andy Cripps. When I started the contest, I did not realize how important durability would be. The camera mount has snapped off of every one of the designs I have flown except these. Basically, the camera mount ends up taking the impact of a lot of crashes (which isn&

) by Andy Cripps. When I started the contest, I did not realize how important durability would be. The camera mount has snapped off of every one of the designs I have flown except these. Basically, the camera mount ends up taking the impact of a lot of crashes (which isn& ;t good for the camera either). This designer&

;t good for the camera either). This designer& ;s camera mount, which has three connectors, outperformed the other designs. Also, the battery clip and motor clips are exactly the right size (or perhaps a bit small?) and therefore do a better job at holding the parts in place, which also important for durability. Congratulations.

;s camera mount, which has three connectors, outperformed the other designs. Also, the battery clip and motor clips are exactly the right size (or perhaps a bit small?) and therefore do a better job at holding the parts in place, which also important for durability. Congratulations.

(and

(and  ) by Andy Cripps. When I started the contest, I did not realize how important durability would be. The camera mount has snapped off of every one of the designs I have flown except these. Basically, the camera mount ends up taking the impact of a lot of crashes (which isn&

) by Andy Cripps. When I started the contest, I did not realize how important durability would be. The camera mount has snapped off of every one of the designs I have flown except these. Basically, the camera mount ends up taking the impact of a lot of crashes (which isn& ;t good for the camera either). This designer&

;t good for the camera either). This designer& ;s camera mount, which has three connectors, outperformed the other designs. Also, the battery clip and motor clips are exactly the right size (or perhaps a bit small?) and therefore do a better job at holding the parts in place, which also important for durability. Congratulations.

;s camera mount, which has three connectors, outperformed the other designs. Also, the battery clip and motor clips are exactly the right size (or perhaps a bit small?) and therefore do a better job at holding the parts in place, which also important for durability. Congratulations.

SECOND PLACE:  by ahmadnazree. The design is extremely light, and yet the clips are spaced far apart -- hence in in line-of-sight flight it has the best flight characteristics of any of the designs. (Probably because it is light; possibly something about the center of gravity vs where the propellers are?) However, the problem with the design is it is extremely fragile and therefore hard to use despite many times super-gluing it back together after crashes. Also the battery clip is a bit too big so the battery slides around. I might try printing it in glass-filled nylon, which is expensive...but maybe more durable?

by ahmadnazree. The design is extremely light, and yet the clips are spaced far apart -- hence in in line-of-sight flight it has the best flight characteristics of any of the designs. (Probably because it is light; possibly something about the center of gravity vs where the propellers are?) However, the problem with the design is it is extremely fragile and therefore hard to use despite many times super-gluing it back together after crashes. Also the battery clip is a bit too big so the battery slides around. I might try printing it in glass-filled nylon, which is expensive...but maybe more durable?

by ahmadnazree. The design is extremely light, and yet the clips are spaced far apart -- hence in in line-of-sight flight it has the best flight characteristics of any of the designs. (Probably because it is light; possibly something about the center of gravity vs where the propellers are?) However, the problem with the design is it is extremely fragile and therefore hard to use despite many times super-gluing it back together after crashes. Also the battery clip is a bit too big so the battery slides around. I might try printing it in glass-filled nylon, which is expensive...but maybe more durable?

by ahmadnazree. The design is extremely light, and yet the clips are spaced far apart -- hence in in line-of-sight flight it has the best flight characteristics of any of the designs. (Probably because it is light; possibly something about the center of gravity vs where the propellers are?) However, the problem with the design is it is extremely fragile and therefore hard to use despite many times super-gluing it back together after crashes. Also the battery clip is a bit too big so the battery slides around. I might try printing it in glass-filled nylon, which is expensive...but maybe more durable?

THIRD PLACE:  by walxo. The interlocking modular mechanism works very well, and is very clever. The battery clip works the best of any of the designs. The designer noticed that the camera I am using is actually different from the original camera (which I had not noticed) and corrected the camera mount accordingly. The big problem with the design is the clips that connect to the airplane body; they are too fragile and bendy and cause the mount to oscillate which makes it hard to fly the drone

by walxo. The interlocking modular mechanism works very well, and is very clever. The battery clip works the best of any of the designs. The designer noticed that the camera I am using is actually different from the original camera (which I had not noticed) and corrected the camera mount accordingly. The big problem with the design is the clips that connect to the airplane body; they are too fragile and bendy and cause the mount to oscillate which makes it hard to fly the drone

by walxo. The interlocking modular mechanism works very well, and is very clever. The battery clip works the best of any of the designs. The designer noticed that the camera I am using is actually different from the original camera (which I had not noticed) and corrected the camera mount accordingly. The big problem with the design is the clips that connect to the airplane body; they are too fragile and bendy and cause the mount to oscillate which makes it hard to fly the drone

by walxo. The interlocking modular mechanism works very well, and is very clever. The battery clip works the best of any of the designs. The designer noticed that the camera I am using is actually different from the original camera (which I had not noticed) and corrected the camera mount accordingly. The big problem with the design is the clips that connect to the airplane body; they are too fragile and bendy and cause the mount to oscillate which makes it hard to fly the drone

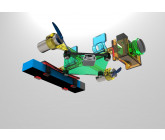

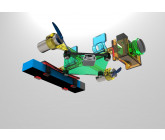

FOURTH PLACE:  by design territory. The mounts for the flight controller are a nice touch.

by design territory. The mounts for the flight controller are a nice touch.

by design territory. The mounts for the flight controller are a nice touch.

by design territory. The mounts for the flight controller are a nice touch.

Note that I think only first place gets the money, I& ;m afraid

;m afraid

;m afraid

;m afraid

As a reminder, I do not wish to have exclusive rights to any of the designs; please feel free to post them anywhere. After a bit more flying I will probably post another contest to build on what I& ;ve learned from here. Eventually I&

;ve learned from here. Eventually I& ;ll post some flight video at my youtube channel "Drone Bites Man FPV"

;ll post some flight video at my youtube channel "Drone Bites Man FPV"

;ve learned from here. Eventually I&

;ve learned from here. Eventually I& ;ll post some flight video at my youtube channel "Drone Bites Man FPV"

;ll post some flight video at my youtube channel "Drone Bites Man FPV"

OK, I& ;m ready to announce the winner. First, some things I learned, which I did not expect and were not in the contest requirements. 1. The two-clip design is crucial, because otherwise the mount starts to oscillate. 2. a durable design is crucial when printing in nylon -- this stuff is just not as robust as plastic.

;m ready to announce the winner. First, some things I learned, which I did not expect and were not in the contest requirements. 1. The two-clip design is crucial, because otherwise the mount starts to oscillate. 2. a durable design is crucial when printing in nylon -- this stuff is just not as robust as plastic.

;m ready to announce the winner. First, some things I learned, which I did not expect and were not in the contest requirements. 1. The two-clip design is crucial, because otherwise the mount starts to oscillate. 2. a durable design is crucial when printing in nylon -- this stuff is just not as robust as plastic.

;m ready to announce the winner. First, some things I learned, which I did not expect and were not in the contest requirements. 1. The two-clip design is crucial, because otherwise the mount starts to oscillate. 2. a durable design is crucial when printing in nylon -- this stuff is just not as robust as plastic.

Currently in the lead are  by ahmad nazree and

by ahmad nazree and  and

and  by andy cripps. I have got these designs to fly successfully using line of sight.

by andy cripps. I have got these designs to fly successfully using line of sight.  by ahmad nazree is a little fragile though and the camera mount broke off on the second flight. I have not tried anything FPV yet.

by ahmad nazree is a little fragile though and the camera mount broke off on the second flight. I have not tried anything FPV yet.

by walxo and

by walxo and  by design territory also appear to meet all requirements. I have had trouble getting

by design territory also appear to meet all requirements. I have had trouble getting  to fly successfully; it turns out if a mount is too short the propellers and mount start to oscillate. I did not realize that would happen.

to fly successfully; it turns out if a mount is too short the propellers and mount start to oscillate. I did not realize that would happen.

by supra 77 has only 1 clip;

by supra 77 has only 1 clip;  by vit gean has only 2 clips. Technically, I wanted both 1 clip and 2 clip designs, so these do not meet requirements, but I have tried printing them anyway.

by vit gean has only 2 clips. Technically, I wanted both 1 clip and 2 clip designs, so these do not meet requirements, but I have tried printing them anyway.

by sava has only 1 clip. Sava also has another 2 clip design,

by sava has only 1 clip. Sava also has another 2 clip design,  , but the flight controller would be mounted upside down. Technically one can flip a flight controller in betaflight so I will try printing those as well even though there are some issues with meeting requirements.

, but the flight controller would be mounted upside down. Technically one can flip a flight controller in betaflight so I will try printing those as well even though there are some issues with meeting requirements.

by ahmad nazree and

by ahmad nazree and  and

and  by andy cripps. I have got these designs to fly successfully using line of sight.

by andy cripps. I have got these designs to fly successfully using line of sight.  by ahmad nazree is a little fragile though and the camera mount broke off on the second flight. I have not tried anything FPV yet.

by ahmad nazree is a little fragile though and the camera mount broke off on the second flight. I have not tried anything FPV yet. by walxo and

by walxo and  by design territory also appear to meet all requirements. I have had trouble getting

by design territory also appear to meet all requirements. I have had trouble getting  to fly successfully; it turns out if a mount is too short the propellers and mount start to oscillate. I did not realize that would happen.

to fly successfully; it turns out if a mount is too short the propellers and mount start to oscillate. I did not realize that would happen. by supra 77 has only 1 clip;

by supra 77 has only 1 clip;  by vit gean has only 2 clips. Technically, I wanted both 1 clip and 2 clip designs, so these do not meet requirements, but I have tried printing them anyway.

by vit gean has only 2 clips. Technically, I wanted both 1 clip and 2 clip designs, so these do not meet requirements, but I have tried printing them anyway. by sava has only 1 clip. Sava also has another 2 clip design,

by sava has only 1 clip. Sava also has another 2 clip design,  , but the flight controller would be mounted upside down. Technically one can flip a flight controller in betaflight so I will try printing those as well even though there are some issues with meeting requirements.

, but the flight controller would be mounted upside down. Technically one can flip a flight controller in betaflight so I will try printing those as well even though there are some issues with meeting requirements.

I am about halfway through testing at this point. There were some submitted in the latter half of the contest that unfortunately I could not print or did not appear to meet the requirements in the powerpoint (PPT). I printed using 3dhubs; if 3dhubs returned errors I could not print them.  by Alzazari_tech returned printing errors.

by Alzazari_tech returned printing errors.  and others by sherifelsheikh also returned printing errors.

and others by sherifelsheikh also returned printing errors.  by vipin kadambur had holes that were a bit too large for the flight controller screws.

by vipin kadambur had holes that were a bit too large for the flight controller screws.  by Fadi Sayegh the camera mount was too small or flight controller mount too large.

by Fadi Sayegh the camera mount was too small or flight controller mount too large.  by R.Vasanth did not have all three designs required in the PPT.

by R.Vasanth did not have all three designs required in the PPT.  by Darcas had a battery mount of an incorrect size. (The batteries&

by Darcas had a battery mount of an incorrect size. (The batteries& ; cross-sections are rectangles not squares.)

; cross-sections are rectangles not squares.)  by AnwarDM and

by AnwarDM and  by MS22 Design both had propeller mounts that were too small (not enlarged to 7mm).

by MS22 Design both had propeller mounts that were too small (not enlarged to 7mm).  by LickuidCAD had the camera mount upside down.

by LickuidCAD had the camera mount upside down.  by Islam Heikal the screw holes for mounting the flight controller appear to be missing

by Islam Heikal the screw holes for mounting the flight controller appear to be missing

by Alzazari_tech returned printing errors.

by Alzazari_tech returned printing errors.  and others by sherifelsheikh also returned printing errors.

and others by sherifelsheikh also returned printing errors.  by vipin kadambur had holes that were a bit too large for the flight controller screws.

by vipin kadambur had holes that were a bit too large for the flight controller screws.  by Fadi Sayegh the camera mount was too small or flight controller mount too large.

by Fadi Sayegh the camera mount was too small or flight controller mount too large.  by R.Vasanth did not have all three designs required in the PPT.

by R.Vasanth did not have all three designs required in the PPT.  by Darcas had a battery mount of an incorrect size. (The batteries&

by Darcas had a battery mount of an incorrect size. (The batteries& ; cross-sections are rectangles not squares.)

; cross-sections are rectangles not squares.)  by AnwarDM and

by AnwarDM and  by MS22 Design both had propeller mounts that were too small (not enlarged to 7mm).

by MS22 Design both had propeller mounts that were too small (not enlarged to 7mm).  by LickuidCAD had the camera mount upside down.

by LickuidCAD had the camera mount upside down.  by Islam Heikal the screw holes for mounting the flight controller appear to be missing

by Islam Heikal the screw holes for mounting the flight controller appear to be missing

GENERAL NOTICE 3 Thank you everyone for your entries! I submitted the last designs for printing today, and in at most 10 days I will come back with the winner. I thought the overall quality was very high and I received many more entries than I expected. Thank you again.

GENERAL NOTICE 2 -- since so many of the designs don& ;t print in ABS, and since I didn&

;t print in ABS, and since I didn& ;t specify ABS in the original requirements, I&

;t specify ABS in the original requirements, I& ;m printing the test runs in nylon using FDM/MJF

;m printing the test runs in nylon using FDM/MJF

;t print in ABS, and since I didn&

;t print in ABS, and since I didn& ;t specify ABS in the original requirements, I&

;t specify ABS in the original requirements, I& ;m printing the test runs in nylon using FDM/MJF

;m printing the test runs in nylon using FDM/MJF

NOTE TO ALL ENTRANTS -- please allow up to 10 days after contest closes for a winner to be selected, as I am printing and testing everything. I do not wish to own the intellectual property for any of the designs, and if you (including the eventual winner) want to post your designs to thingverse or other site you are welcome to do so

by ahmadnazree -- missing two mounting holes for the flight controller. technically, one can mount the flight controller with only two holes (and it saves weight on screws/bolts) but it makes me nervous, the flight controllers are expensive ($60ish)

by ahmadnazree -- missing two mounting holes for the flight controller. technically, one can mount the flight controller with only two holes (and it saves weight on screws/bolts) but it makes me nervous, the flight controllers are expensive ($60ish)

by walxo -- don&

by walxo -- don& ;t have all parts so can&

;t have all parts so can& ;t print, hence unrated

;t print, hence unrated

by MS22 Design -- also in the lead, although not yet flight tested anything

by MS22 Design -- also in the lead, although not yet flight tested anything

by Dev Shah -- the direction of the flight controller has been changed. For tiny whoops, traditionally the flight controller is on the diagonal

by Dev Shah -- the direction of the flight controller has been changed. For tiny whoops, traditionally the flight controller is on the diagonal

by Andy Cripps -- still in the lead, meets all requirements, although not yet tried flight testing anything

by Andy Cripps -- still in the lead, meets all requirements, although not yet tried flight testing anything

by Anwar DM -- I get errors when I try to print it

by Anwar DM -- I get errors when I try to print it

by sava -- I appreciate the creativity and rearrangement of parts. I get errors when I try to print it though, and the direction of the flight controller has been changed. For tiny whoops, traditionally the flight controller is on the diagonal

by sava -- I appreciate the creativity and rearrangement of parts. I get errors when I try to print it though, and the direction of the flight controller has been changed. For tiny whoops, traditionally the flight controller is on the diagonal

Drone Bites Man

Buyer