So, you’re ready to design a brand-new product. Congratulations! You hired that freelance product designer and you’re knowledgeable enough in SolidWorks to be dangerous. You’re ready to hit the ground running and create a brand-new product design that will change the world. Maybe it’s a new spacesuit for astronauts to use or the newest form of an ergonomic office chair.

Here’s the problem. What’s next? Don’t get me wrong—it’s great that you’ve taken the first steps and hired a freelance designer or drafter. But now you have to actually come up with a new product, and that is not exactly an easy task. If it were, you would already have done it and probably wouldn’t need a specific designer to get your new product created and off the ground. Every new product that you’ve ever seen has gone through the process and has been reiterated many times before getting through to the customer.

Think about Apple products or a new car. These products have all transformed and been redesigned throughout their existence. Even the iconic Apple phones weren’t fully formed in the heads of Steve Jobs and his employees when they first conceived of the idea. CAD services and New product development is a process, one that takes significant time and investment.

If you’re not to the point of starting the actual product design process, you can take a look at hiring a freelance 3D modeling designer on many of the other articles on this site. You may still be investigating whether you want to start a business to develop this product or whether you’re interested in creating something simply for your own personal use. Once you know that you want to design a new product, we can look at the process of product and industrial design.

There are seven main steps to the process of creating a new product or performing industrial design. These stages come in different shapes and forms, and you don’t necessarily have to follow or complete every single one of them. However, this process is the most common sense and direct way to get your product from just being an idea in your head to being a product on a shelf.

1. Idea Generation

You may think that at this stage in the game, you should already have a product idea, and that is in many ways true. However, you likely only have a general idea. This is the point where you have to come up with some concrete ideas. Idea generation is the time for sketch pads, sticky notes, and lots of coffee in a conference room to try and come up with numerous iterations of your product.

Let’s say you were designing a brand-new cell phone for Apple back in the early 2000s. You need to make a few decisions and craft them to see what they might look like when they’re complete. Perhaps you have an idea for another flip phone, as those have been on the market for a while, and the world is fairly familiar with them—so you sketch one up as an idea.

Then, you think of other iterations, including the all-too iconic iPhone. Your goal here is actually quantity over quality—you want as many different ideas and iterations as you can imagine so that you have plenty to work with. The more choices you have, the better.

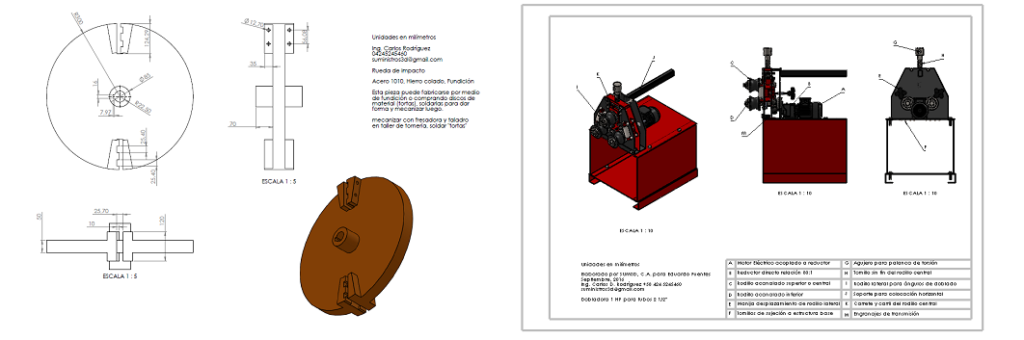

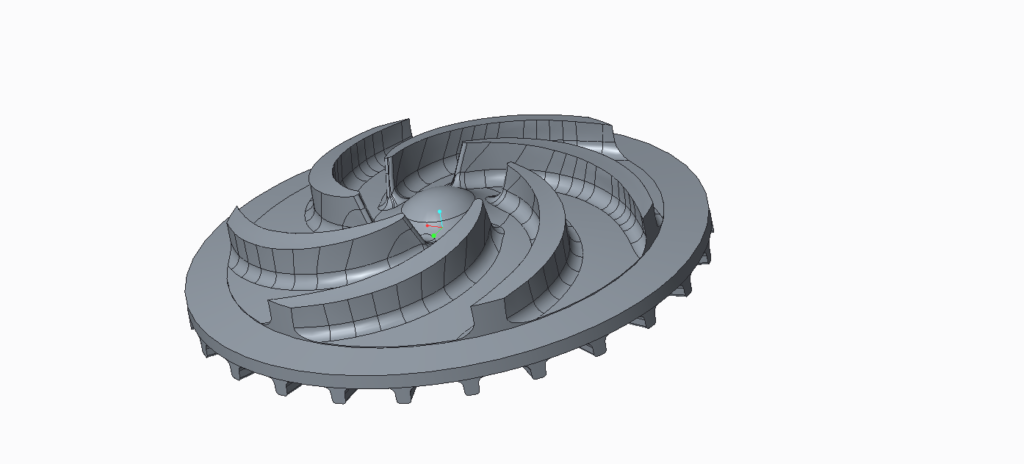

Now, where does 3D CAD design come into all of this? There are a couple of ways in which CAD can be incorporated into this part of the process, or at least must be considered. If you take the appropriate steps with your freelance designer now, you will save yourself some trouble later. First, your sticky notes and sketches could be in the form of CAD designs. When you are going through all of these iterations, you may choose to simply put them down in a virtual format from the get-go. This will be a time-consuming process, but there are ways to make it simpler.

Using CAD, your designer can just put the bare bones of the idea in, allowing you to start from scratch to have a simplistic design that acknowledges the necessary design aspects. The initial drawing may take a bit longer than sketching the idea on a piece of paper, but it will be well worth it.

You will notice as you go through your idea generation process that many of the designs are strikingly similar, especially after one idea has been thrown out. Other ideas tend to flow naturally from the bones of what we see in front of us, so the structure of an idea will help us come up with more. Because of that, your CAD sketch will suddenly become extremely useful. You can take that initial sketch and modify it, making new copies for each different idea you generate. Maybe you end up coming across a completely different idea that can’t use the same structure. That’s fine, you’ll still have created a basis for numerous ideas that may be useful to yourself or other groups later.

Having this design in place at this stage is extremely useful, as well. You can ensure general features and size are accurate and start to piece together a larger project. When you come to the actual design phase, you’ll be thankful because you started with an actual CAD design—so the beginning stages of that process have already started.

2. Idea Screening

Idea screening is where you get to be mean. You have probably generated somewhere in the neighborhood of ten to twenty legitimate ideas at this point. That’s a great number, but now your goal is to get it down to one or two. Idea screening is the step where you have to take an honest and critical look at each of the designs you made in the last step and decide whether or not they are valid and worthy of sticking around.

The idea generation stage can tend to get a little bit crazy, which is perfectly acceptable. Many great ideas have come out of the chaos of an idea generation meeting gone off the rails. The question “What if?” can have some interesting answers that can end up being extremely useful when you want to create a groundbreaking product.

However, more than likely, these designs have become trash that needs to be scraped away so that you can get to the real heart of the design. Idea screening is where you take these designs and hold them up to a scrutinizing microscope and ask if they are feasible, and beyond that, if they are worth it.

Let’s say you have designed your twenty different phone ideas and come up with some excellent possibilities. You have your flip phone, your iconic iPhone, and many other ideas. Perhaps you even have some crazy ones, like a phone that simply projects the information onto your retina, or one that has a foldable screen (which is now a reality, but fifteen years ago was a bit difficult). You have to look at these designs honestly and decide what to do with them.

The projector phone is easy—that one you can quickly and clearly say is too much and is extremely infeasible. Maybe in fifty years, it will become a reality, but it is not worth wasting your time trying to develop. The folding screen phone, however, is more feasible but requires a lot more work and energy. Your question now is—is that phone idea worth the effort? In this case, it’s not, so you can remove those ideas from your list and move on. You’ll be better off for it.

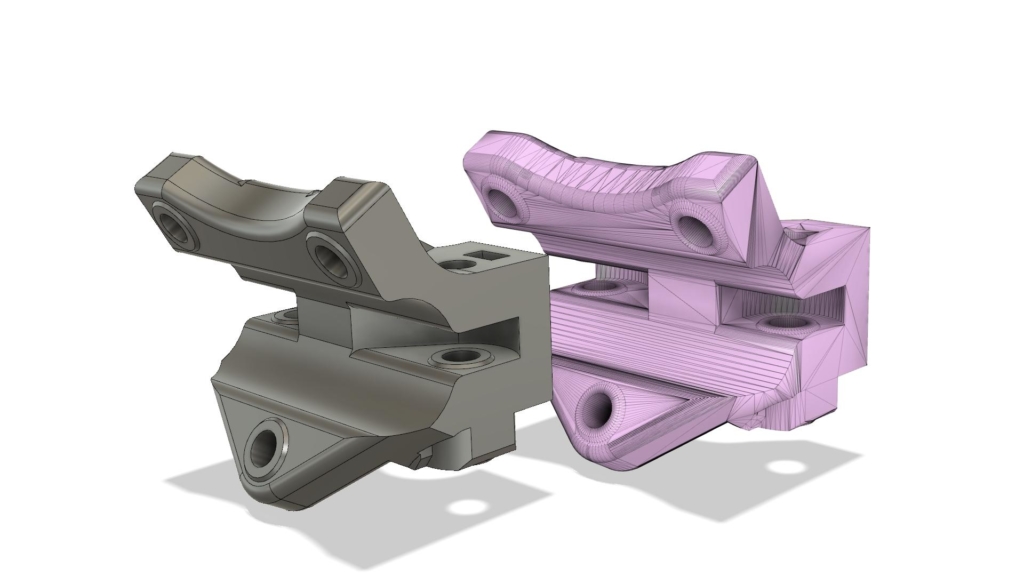

When you incorporate your 3D designs into this stage of the process, you can be even more scrutinizing. Obviously, you don’t have completely fleshed out ideas that are fully realized in the digital realm yet, but you have a general overview. This can still tell you a lot about the future product and whether it is worth attempting to create.

Maybe the CAD design will show you that it already looks too complex with the various features you want to incorporate—or perhaps it seems like it will be too bulky. An accurately scaled drawing in a CAD program can give you a bit more insight into the project than a sketch can—even if it is just a stick diagram. This can help you screen your ideas more effectively.

3. Concept Development and Testing

Onto development and testing! The previous couple of steps can be time-consuming, and oftentimes, they may take a lot longer than you initially imagine. For instance, you could repeat those steps multiple times, especially if you end up scrapping all of your initial ideas. Or, on the other end of the spectrum, you realized you could incorporate entirely new ideas, but you have to change the scope of the project to accommodate them.

A lot can change in a short period of time, and so those two steps can become quite repetitive. Stick with it, and you’ll find yourself as the development and testing stage—preparing you for the creation of a new product. This is the moment you’ve been waiting for. No, you won’t be manufacturing it yet, but at the end of this stage, you will have a virtual product.

Let’s say you ended up with three designs that were feasible at the end of the last stage. That’s fine. In this phase, we’ll narrow it down all the way to your final product. If you’ve already centered your efforts on one, even better! This stage is more a lesson in a concentrated effort, whereas the first two were more about the breadth of ideas.

Take your ideas and begin fleshing them out. You get to incorporate the meat of the design into the products during this stage, creating artistic and visually appealing designs. Your CAD design service will work with you to create a mock-up of the fully finished piece, whatever it looks like. You will spend a great deal of time and effort trying to finalize the different portions of your ideas and get them on the computer screen. Take your time here, because the more detail and specificity you incorporate now, the easier it will be in the end.

Once you have crafted your designs, you will have one or a handful of fully-fledged concepts. These are your products, and one of them will be your final creation—the product of all of your efforts in this stage. However, now you have to test them. Even if you only have one, testing is crucial, because there are issues that may arise that need correcting, and you don’t want to have to correct them later.

You don’t need to build the actual product to complete testing on it at this point. Certainly, there are tests that should eventually be performed on a finished product, but at this point, you need to find potential issues with production and manufacturing, or obvious issues. You can run stress tests in the CAD software, or you can examine the size and shape of the different designs to see which are most feasible and which will be most appealing to consumers. These tests will narrow down your product and likely send you back to the beginning of this stage to do a few quick redesigns before presenting the product to the market.

4. Marketing Strategy Development

You may be thinking at this point, “didn’t I hire a marketing team to take care of the marketing strategy for me? Why do I need to develop a marketing strategy for this new product design?” Or, you may have already assumed you’ll be involved with the marketing strategy because you are the product designer, and you know the product best.

Either way, let’s make it clear—you are going to be involved in the marketing strategy. When you design a product, you automatically become an expert in that product and should be intimately involved in the marketing process because you can speak to its strengths and address its weaknesses better than any hired hand.

We don’t need to get into the nitty-gritty of how to develop a marketing strategy, but there are a few things that you need to know and include that will be informed by the decisions and actions you have made in the previous steps. A marketing strategy is the beginning of your sales process, and this is how your product will get off the shelves when it is finally released. You need to make the customer want it.

First off, you should let your customers know what problem you’re trying to solve. They’ll want to see a cool product, but if you advertised the first iPhone and didn’t tell anyone that it was a smartphone, you wouldn’t have seen sales as drastic in the first few months. Sure, it likely would have eventually taken off, but it would have taken longer, and it may not have been as successful. Let them know why you built this product and what you wanted to create for them.

After that, tell the customers what you’ve done—let them know why it was the final design (it was the most rugged or had the most features, etc. This is your opportunity to brag on the design). When you’ve gone through all of the design and testing steps that we have examined here, you should have a lot of things to say about your design, and these will all be features you want to capitalize on in your marketing strategy.

If you’ve been diligent and have created a CAD design throughout this process, you’re only a couple of steps away from creating a stunning visual display. Your freelance industrial designer will take the ideas you’ve created and put them into a real-world simulation of the product. With virtual reality, you can create designs that look as real as the world around you, and this will be your best marketing tactic yet. Create a realistic rendering of the product and plaster it on web pages, advertisements, and more. Suddenly, you have a real, visual marketing campaign.

5. Business Analysis

The next step in the process is business analysis. This is the part of the journey where you start to examine profits and sales margins, price and quantity, and the like. You need to know that your new product will be profitable because the end goal here is always to help your business grow.

Take a look around you at similar products and companies to see what they’re doing. This can help you set price targets and comparable goals. While you’re doing all of this, however, take a look at what your initial goals were. You likely set out with the idea in mind that you wanted to create a product that would sell well so you could earn $1 million or some other target. Will your product make that much? And what price do you need to sell it at to make that happen?

This is a very business and economics heavy question, so it’s difficult to answer all in one go. But it is another area your CAD design can help you, surprisingly.

If you look at your design, this finalized and realized product sketch, you can see many small details that will help with this decision. Most fundamentally, it will give you an idea of how much it will cost to make the product. For your new cell phone, for example, you’ll notice that your sketch has incorporated a screen, an aluminum case, microprocessors in the interior, screws, and similar assorted parts and pieces. You can begin looking at these individual pieces and pricing them out to see how much money you need to spend on the product to even create it. You obviously will need to offset your expenses and sell at a higher price, so this gives you the absolute minimum baseline you need to begin making a profit.

Additionally, your product design should show you some of the selling features of your product. Being new and advanced, you’ll likely be able to command a higher price than similar products on the market, so you can look at the included features and try to assess how much they will be valued at.

Depending on this, you can increase the price target from there and set a goal in mind for how much money you want to make. When this is complete, you will have an idea in mind of your product and the profit you are shooting for. There are many other considerations with a business analysis, but the CAD design helps you to accurately assess the product itself so you can set your prices and target margins accordingly.

6. Product Development

Is it done yet? Are we there yet? Your product is now ready to be created. You have worked hard up until this point to define the different parts of this product and to develop a business and marketing plan. Your preparation has led you to the point of having a product waiting to make you money when it’s complete.

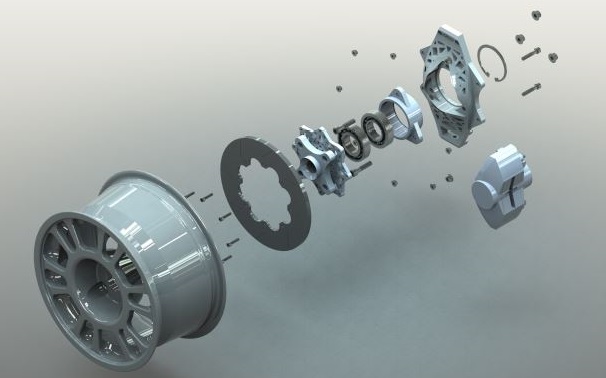

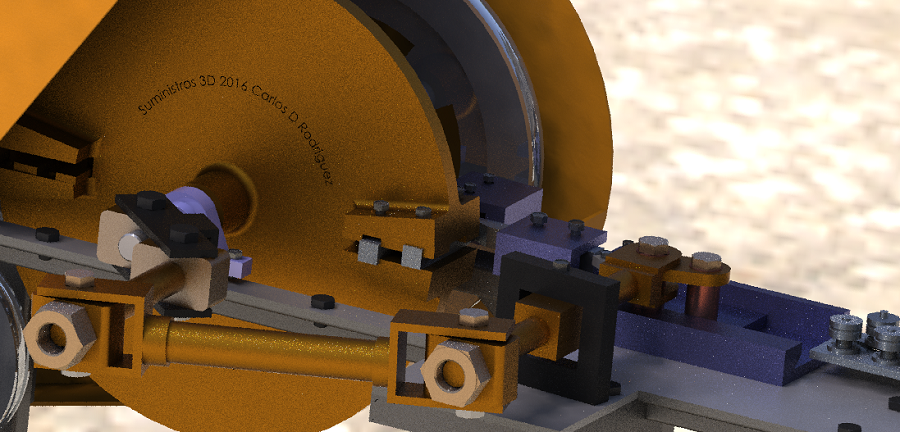

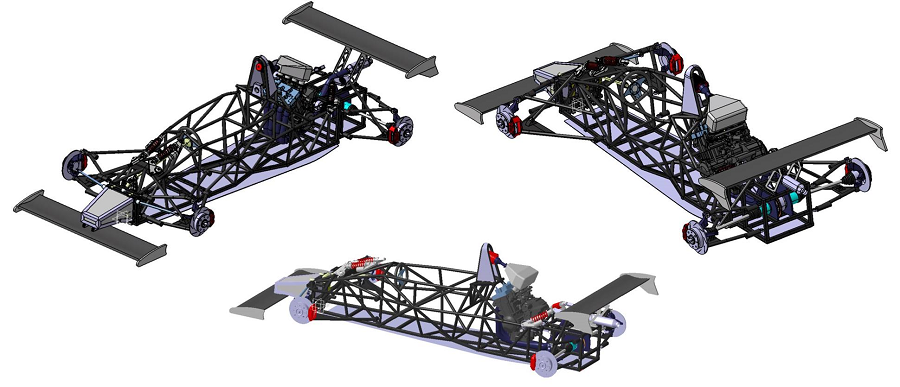

This part can be one of the most difficult because you actually have to create a product. The first thing to do is to take the concept sketch from your CAD designer and create a prototype. That in and of itself can be a lengthy process, but you will need to fabricate an initial product so that you can start the process of testing and marketing, as well as redesigning and preparing for manufacturing. Design for Manufacturing is an incredibly beneficial skill, so you can look out in advance for someone who has the necessary ability to create an initial design that will be easily manufactured and won’t take up too many resources.

Design for Manufacturability is a niche skill that means you have learned how to design a product so that it is compatible with traditional manufacturing techniques. This skill puts some limitations on the design capabilities, but it can be extremely helpful at this stage. The designer will ensure that the product is designed with the final production method in mind, verifying that the component parts are interchangeable and easily procured so that you don’t have all sorts of specialized pieces in the product that are both expensive and time-consuming to make. They will also verify that the way in which a product is manufactured is compatible with the typical production methods of your company – whether it’s assembly line manufacturing, robotic assembly, or something else – and will assess every aspect of the manufacturing process to incorporate it into the design.

This entire stage of the process is very complicated, but it’s useful to have a designer who knows how to create something that is more than just a 3D printed part, or a highly customized piece. Going back to your business analysis – knowing the components will help you bring down prices, and if you keep it simple earlier on, you can ensure your profits are as high as possible.

There will be more testing needed, for sure, once you have created your prototype. You will certainly need to work with customers and salesmen to ensure that everything is properly addressed with your product. This part is the meaty portion of the project because you have boots on the ground and are taking physical action to get this product from the computer screen to the manufacturing floor. Once it is complete, you will have a product that you can put before the world proudly and start selling.

7. Test Marketing

Now that you have a product, you can begin marketing and capitalizing on that design. This is the moment you’ve been waiting for this entire process. The last phase is to begin test marketing the product. There are numerous little steps you can take, but essentially, this final phase is the introduction to selling. You need to introduce the marketing strategy and begin to test out the market to see how receptive they are to the product. This will help you gauge how to navigate the waters of selling a product to the masses.

Your CAD designer, at this point, has helped you create an entire product from scratch. Their designs will help inform the marketing and sales teams of the way to market your product. They can use images that have been designed in their product literature and sales information, and they can take the technical information that was designed into the product for additional selling points. Once you have finished the product, you have got a prototype and a sales strategy, so you are ready to take the design out for the masses to see.

The product’s sales and marketing will only be as good as the actual design is. Take a look at the new truck designed by Tesla that was recently released. It comes from a brand known for performance and style, but it is certainly underwhelming. It looks clunky and inefficient, and it didn’t pass the safety tests that it was touted as achieving. Because of this, sales will likely suffer, even though in every other area, it performs incredibly well. The design, particularly that which is provided by your CAD designer, is the foundation for how well your product performs and eventually sells.

Before you can go and sell a product, no matter how groundbreaking it seems, you need to ensure that you have done everything you can to make it the best product ever. The more effort and energy you spend on the design and ideation phases, the better your product will become in the end. By testing it rigorously and developing a solid marketing plan and business analysis, you will know exactly what you need to create a profitable product and sell it properly to your customers. The other designs you produced during the design generation phase can also inform your business decisions and give you ideas for future products.

Your CAD designer will have helped you and knows this product as well as you do, and by this point, they may even know it better. They can help inform the test marketing groups and help you create an effective strategy to begin selling your product. Remember, this is a product you are launching from a platform they helped create and know intimately well. This product launch will take the best parts of both of your efforts and combine them into something that will be profitable and successful, and hopefully will help people’s lives get better.

Cad Crowd’s Industrial Design Service Can Help

So, there you have it, you have successfully created a product. And not only that, you have developed a marketing strategy and a business analysis, and you have multiple other ideas floating around for potential future iterations or new product ideas. Honestly, you’re halfway towards starting an entire business from scratch, so you might as well keep going.

One of the most important and pervasive things we discussed in this article was the importance of your CAD designer. It may not seem pertinent immediately, but the benefits offered by a competent freelance designer, or skilled drafter of any sort, will certainly help get your product off the ground. Look at them as a resource, a well of information and talent from which to draw inspiration and ability. Their tools will help you create something truly remarkable, and in the end, you will be able to accomplish your goal of creating the most profitable product you can imagine.

There are hundreds of different steps and avenues you can take to develop a new product, and this list is anything but comprehensive. But, if you follow the steps and know what you’re doing, you should be successful. Take a look through Cad Crowd today to find yourself a designer who can help make your product a reality. Regardless of if you follow these action items exactly or if you diverge and take a different path, an industrial designer can help make your product a reality.