Universal Coupling

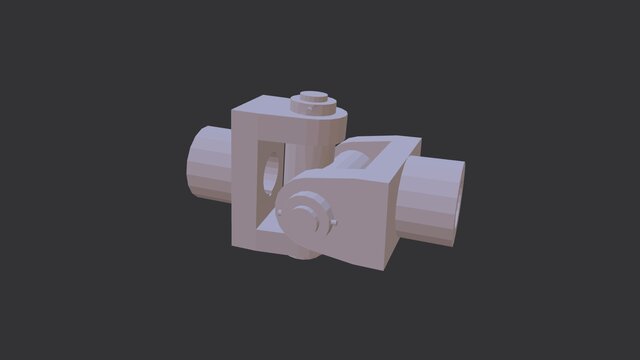

Universal Coupling (Hooke’s Joint)

The Universal Coupling is a precision-engineered mechanical joint designed to transmit rotary motion between two non-collinear shafts that are inclined at an angle. Unlike rigid couplings, it accommodates misalignment by enabling smooth torque transfer through its cross-and-bearing assembly, ensuring continuous power flow even under dynamic angular variations.

Geometric Elegance: The coupling’s symmetric cross structure with forked yokes on each shaft makes it an excellent showcase of parametric modeling and assembly constraints in CAD.

Functional Purpose: Enables reliable power transmission where shafts are not coaxial - widely applied in automobile drive shafts, machine tools, and marine propulsion systems.

Design Considerations: Emphasizes tolerancing for pin–bush connections, clearance for angular swing, and material optimization for fatigue resistance under cyclic loading.

Visualization Value: Its motion simulation in CAD highlights velocity fluctuations (non-uniform angular velocity), making it a classic demonstration for kinematic studies.

The Universal Coupling is not just a mechanical component - it’s an educational tool. Modeling it showcases mastery in assembly relations, joint constraints, motion analysis, and the ability to blend functionality with manufacturability. It’s a component that tells a story of how design meets real-world mechanics.

Files (9)

License:

CC - Attribution

Learn more

Published